Carbonitriding of universal joint bushes

A cross shaft and universal joint technology, applied in the direction of couplings, bearing components, shafts and bearings, etc., can solve the problems of increased wear of the universal joint cross shaft bushing, bearing damage, etc., and achieve long service life and long life. The effect of long life and good tempering stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

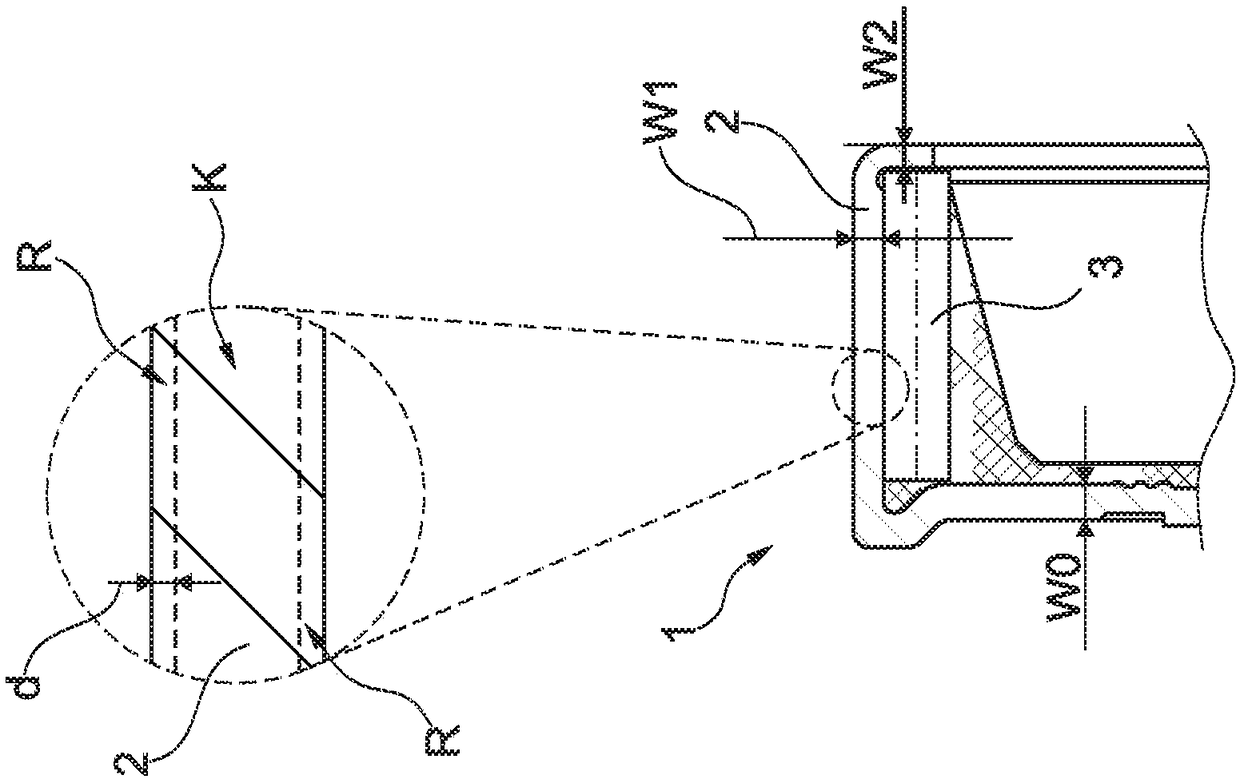

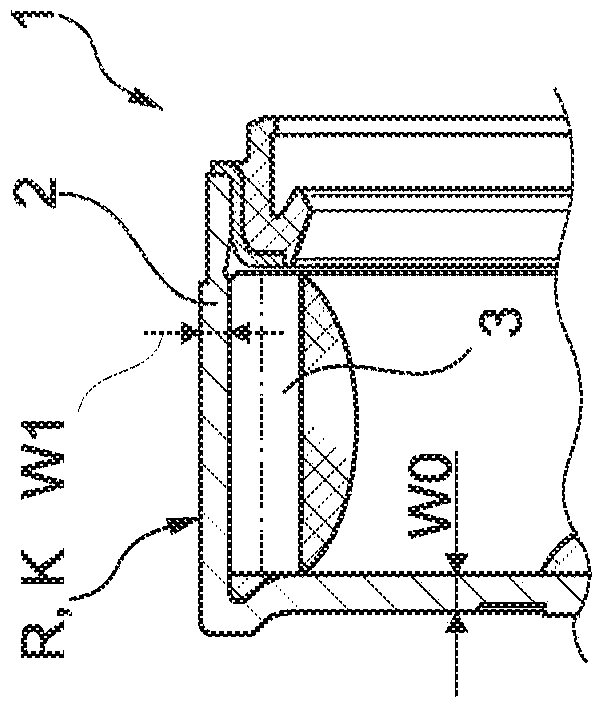

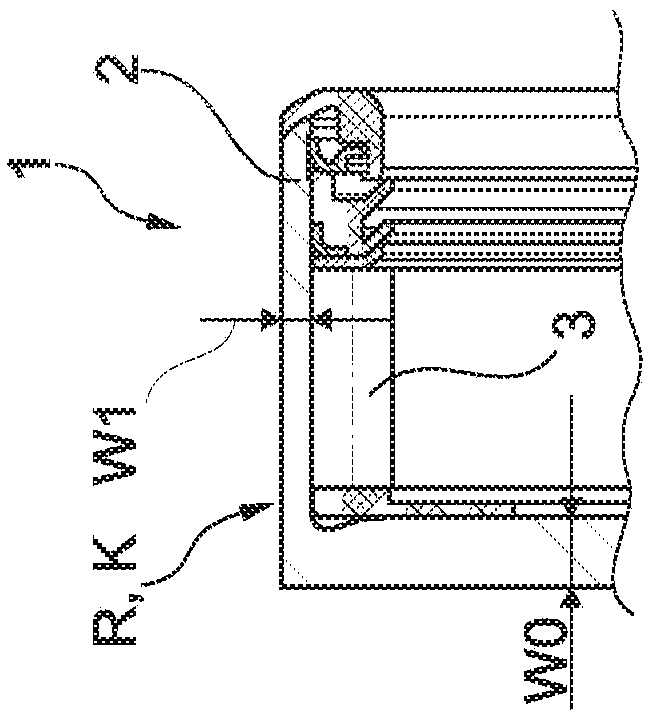

[0058] figure 1 A first embodiment of a universal joint spider bushing for a spider joint used in drive and steering axles of a vehicle is shown, wherein the universal joint spider bushing 1 comprises an outer ring 2 .

[0059] In the present example, the universal joint spider bushing 1 essentially has two vertical parts and one horizontal part, which are connected to one another, in particular constructed in one piece. The described parts together form a cup-shaped joint spider bushing 1 , wherein the shown horizontal parts form the outer ring 2 .

[0060] In the region between these three parts, the rolling bodies of the needle bearing or the rollers 3 of the needle bearing are arranged. At least on the inner side of the cup-shaped joint spider bushing 1 , the horizontal part or outer ring 2 thus forms a rolling-body raceway on which the rollers 3 can roll.

[0061] For the sake of completeness, it should be mentioned that the three described parts of the universal joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com