High-toughness austenite type high-manganese steel plate and production method thereof

A production method, austenitic technology, applied in the field of metallurgy, can solve the problems of high resource consumption pressure and high production cost, achieve uniform structure, ensure the yield and performance of the product, and reduce the effect of low temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

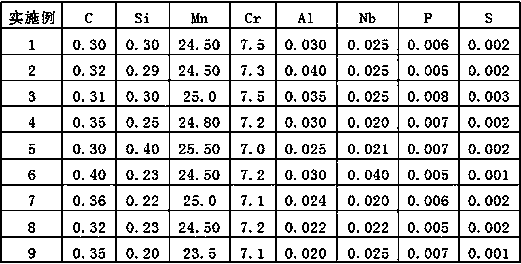

[0035] The thickness of the high-toughness austenitic high-manganese steel plate in this embodiment is 12 mm. The chemical composition and mass percentage of the steel plate are shown in Table 1.

[0036] The production method of the high-toughness austenitic high-manganese steel plate in this embodiment includes steelmaking, continuous casting, heating, rolling and heat treatment processes, and the specific process steps are as follows:

[0037] (1) Steelmaking process: molten steel is first smelted in the primary smelting furnace, using increased slag volume and multiple slag flows, and the tapping temperature is 1625°C; after slag removal, it is refined in an LF furnace to complete the alloying of Mn, Cr, and Nb. When the bag temperature is 1550°C, vacuum treatment is carried out in the VD furnace of the hanging bag; during the vacuum treatment process of the VD furnace, aluminum wire and Si-Ca wire are fed into the molten steel, the vacuum degree is 66Pa during vacuum treat...

Embodiment 2

[0046] The thickness of the high-toughness austenitic high-manganese steel plate in this embodiment is 25 mm. The chemical composition and mass percentage of the steel plate are shown in Table 1.

[0047] The production method of the high-toughness austenitic high-manganese steel plate in this embodiment includes steelmaking, continuous casting, heating, rolling and heat treatment processes, and the specific process steps are as follows:

[0048] (1) Steelmaking process: molten steel is first smelted in the primary smelting furnace, using increased slag volume and multiple slag flows, and the tapping temperature is 1630°C; after slag removal, it is refined in an LF furnace to complete the alloying of Mn, Cr, and Nb. When the bag temperature is 1545 ℃, the hanging bag is vacuum treated in VD furnace; during the vacuum treatment process of VD furnace, aluminum wire and Si-Ca wire are fed into molten steel, the vacuum degree is 66Pa during vacuum treatment, and the vacuum holding ...

Embodiment 3

[0057] The thickness of the high-toughness austenitic high-manganese steel plate in this embodiment is 30 mm, and the chemical composition and mass percentage of the steel plate are shown in Table 1.

[0058] The production method of the high-toughness austenitic high-manganese steel plate in this embodiment includes steelmaking, continuous casting, heating, rolling and heat treatment processes, and the specific process steps are as follows:

[0059] (1) Steelmaking process: molten steel is first smelted in the primary smelting furnace, using increased slag volume and multiple slag flows, and the tapping temperature is 1630°C; after slag removal, it is refined in an LF furnace to complete the alloying of Mn, Cr, and Nb. When the bag temperature is 1545 ℃, the hanging bag is vacuum treated in VD furnace; during the vacuum treatment process of VD furnace, aluminum wire and Si-Ca wire are fed into molten steel, the vacuum degree is 66Pa during vacuum treatment, and the vacuum hold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com