Optical polyvinyl alcohol-based film, method for producing the same, and polarizing film using the optical polyvinyl alcohol-based film

A technology based on polyvinyl alcohol and a manufacturing method, which is applied in the field of polarizing films, can solve the problems of increasing display defects of polarizing films and lowering the quality of displays, and achieve the effects of efficient bubble defects, less display defects, and suppressing the reduction of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0161] (Manufacture of polyvinyl alcohol-based films for optics)

[0162] 1,000 kg of polyvinyl alcohol-based resin with a weight average molecular weight of 142,000 and a degree of saponification of 99.8 mol%, 2,500 kg of water, and 0.2 kg of sodium lauryl sulfate as an anionic surfactant (0.02% by weight relative to the resin) were added to the admixture. After stirring at 90° C. in a pressure dissolving tank, 0.2 kg of polyoxyethylene lauryl ether as a nonionic surfactant (0.02% by weight relative to the resin) and 100 kg of glycerin as a plasticizer were added, and the The temperature was raised in a pressurized state by blowing steam, and it was stirred at 140° C. for 8 hours to dissolve uniformly to obtain a polyvinyl alcohol-based resin aqueous solution (resin concentration: 25% by weight).

[0163] Then, the polyvinyl alcohol-based resin aqueous solution was stored in a storage tank at 140° C. for 18 hours, and then defoamed through a foaming step and a steam exhaust s...

Embodiment 2~5、 comparative example 1~4

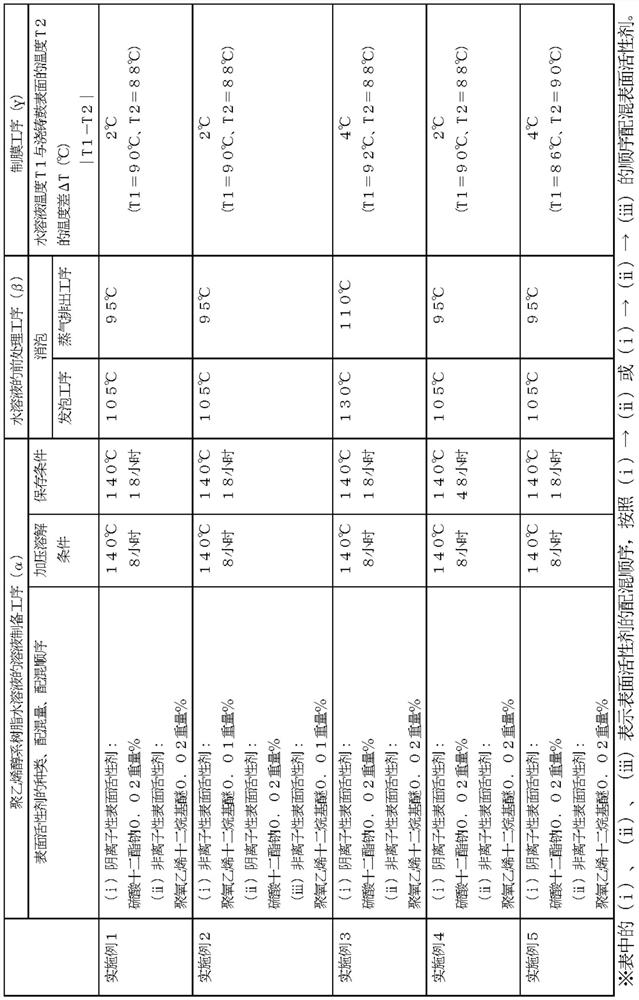

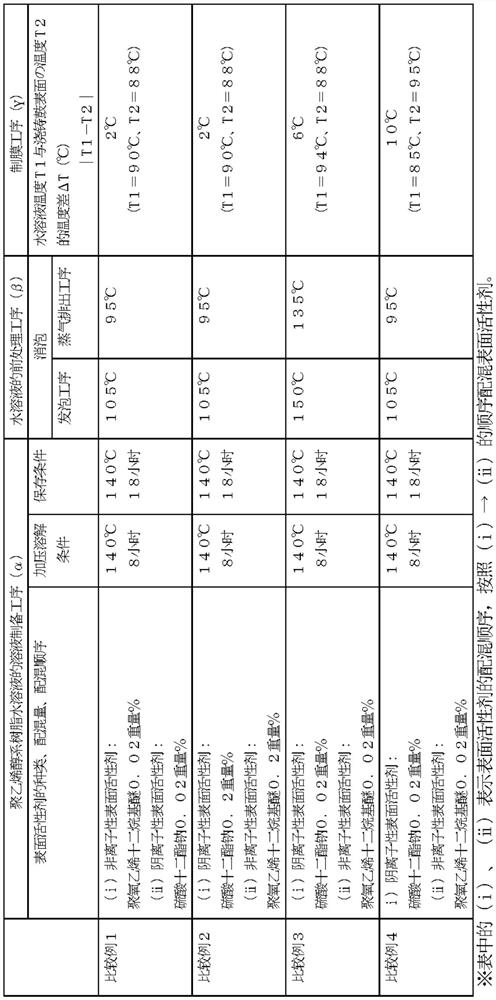

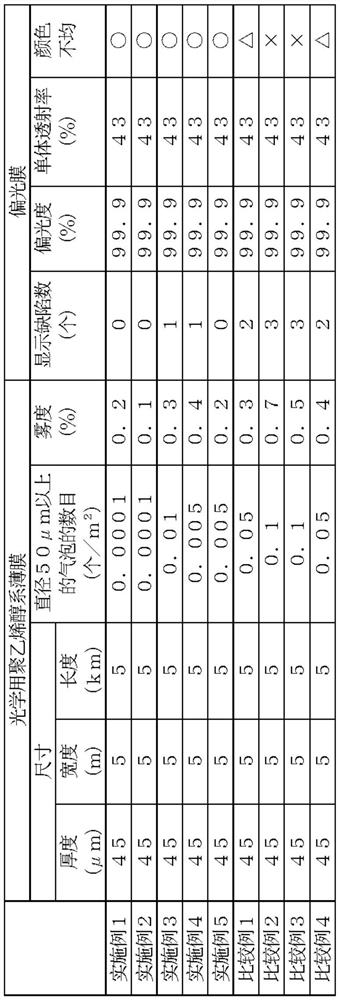

[0175] Except having manufactured under the conditions shown in following Table 1 and Table 2, it carried out similarly to Example 1, and obtained the polyvinyl-alcohol-type film for optics, and a polarizing film. The properties of the obtained optical polyvinyl alcohol-based film and polarizing film are shown in Table 3 below.

[0176] [Table 1]

[0177]

[0178] [Table 2]

[0179]

[0180] [table 3]

[0181]

[0182] From the results, it can be known that the number of bubbles of the optical polyvinyl alcohol-based films of Examples 1 to 5 is within the specific range of the present invention, so the obtained polarizing film has few display defects. Since the number of cells of the polyvinyl alcohol-based film is outside the specific range of the present invention, the obtained polarizing film has many display defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com