Large-surface spraying flexible cable robot

A surface spraying and robot technology, applied in the direction of manipulators, spraying devices, manufacturing tools, etc., can solve the problems that the working range cannot fully meet the requirements, the working range of wall-climbing robots is small, and the safety performance is low, so as to achieve easy operation and high spraying efficiency , the effect of a large working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

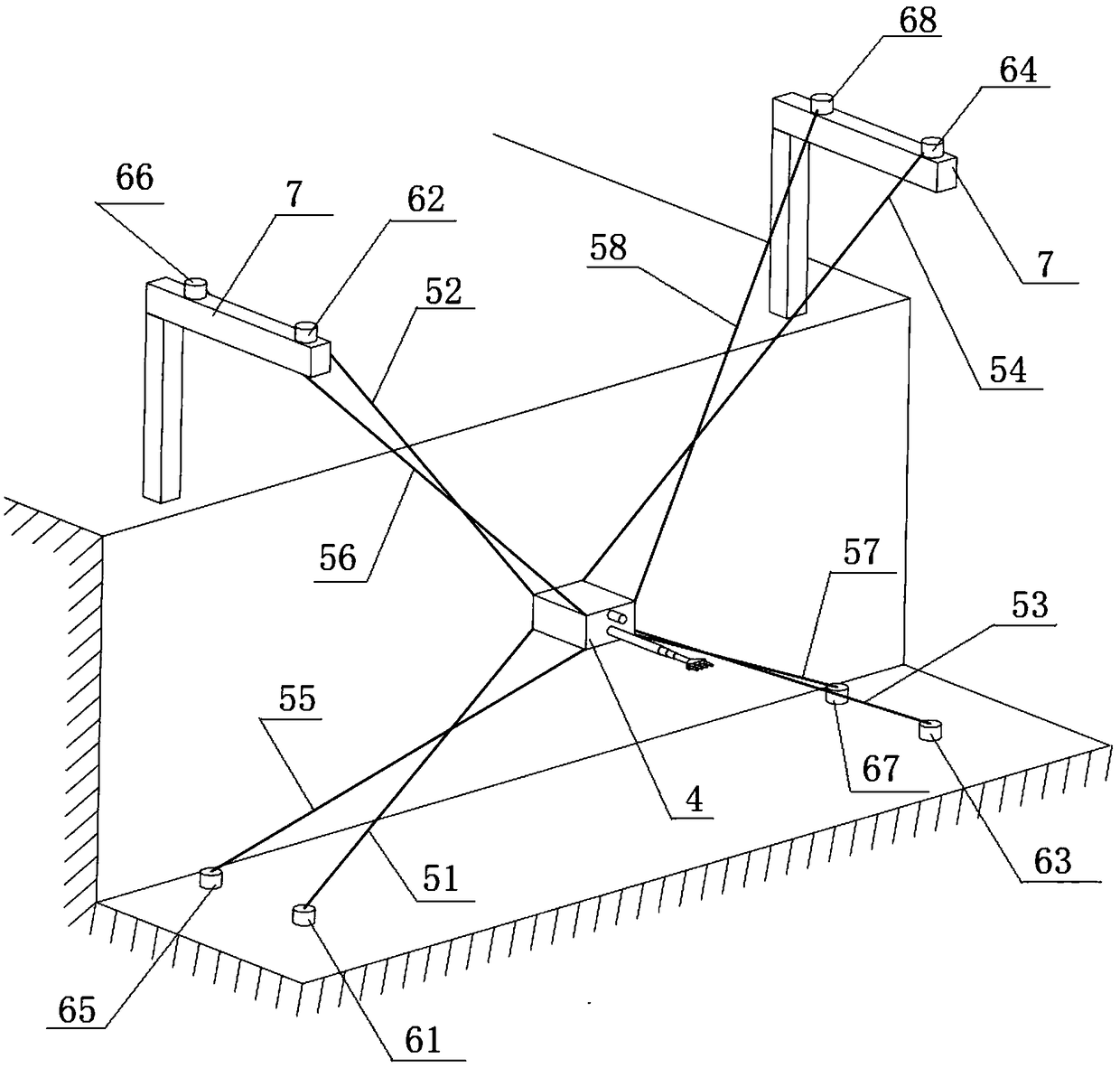

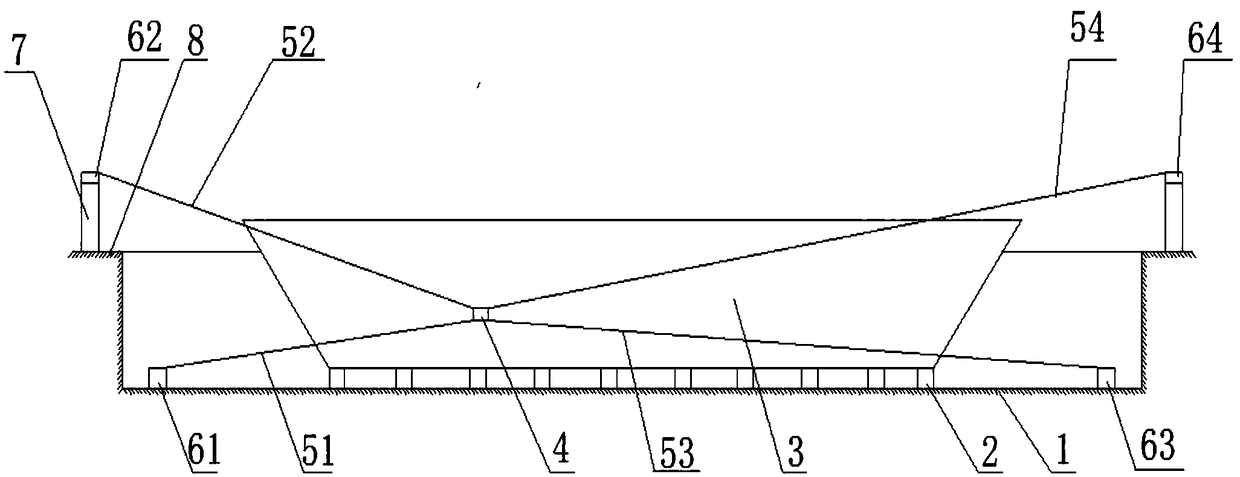

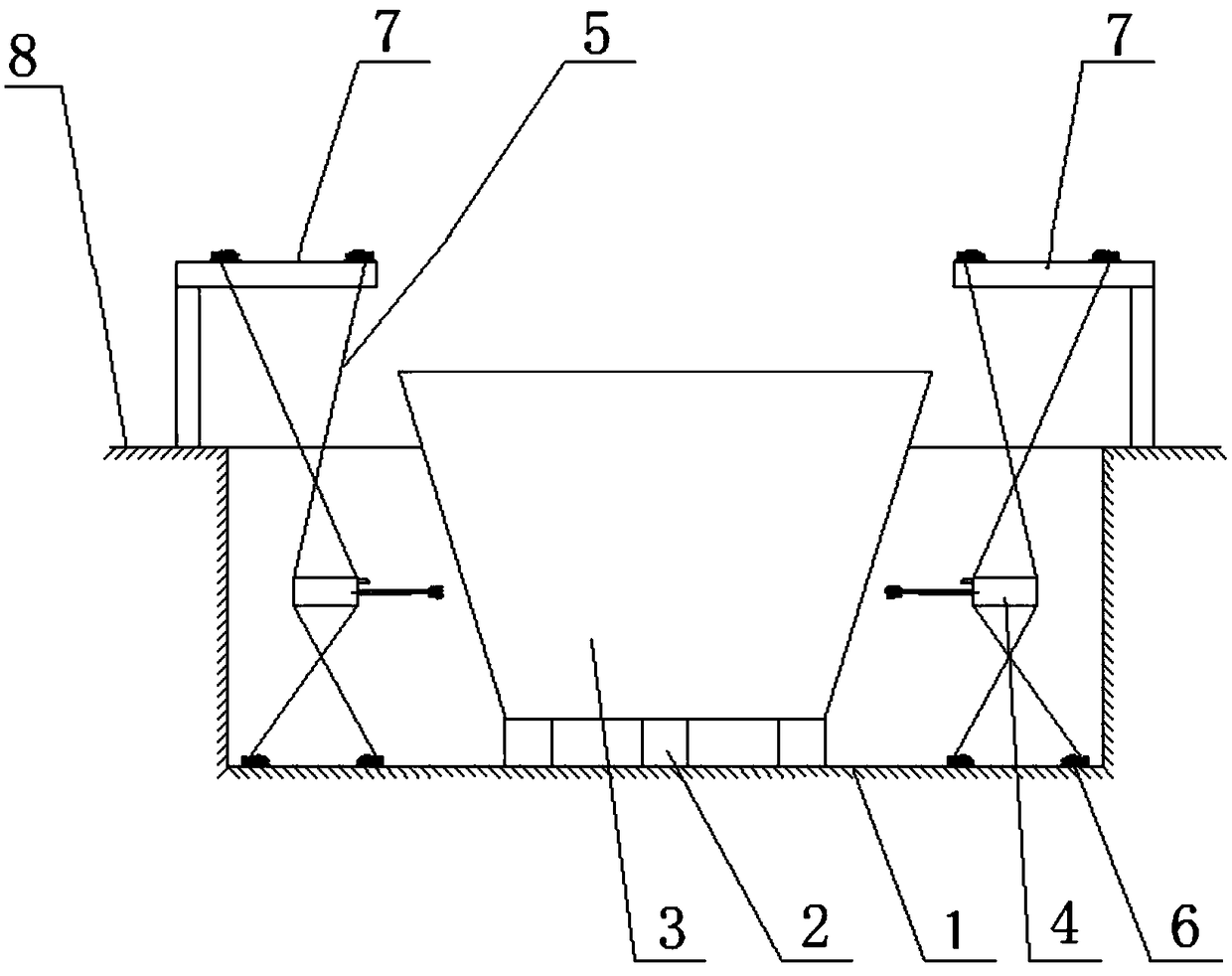

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] The definition of the present invention faces the appended figure 1 When the left side is the left side, the attached figure 1 When the back is right.

[0025] like Figure 1 to Figure 4 As shown, the large-surface spraying cable robot of the present invention is used for surface spraying of ships. The ship 3 is placed on the keel pier 2. The keel pier 2 and the ship 3 are located at the lower part 1 of the dry dock as a whole, and the top surface of the ship 3 is higher than the top of the dry dock. 8.

[0026] Wherein a large surface of ship 3 is provided with spraying device 4, and this spraying device 4 comprises distance measuring device 41, spray pipe 42 and spray gun 43, and described distance measuring device 41 and spray pipe 42 are arranged on the same side of spraying device 4, described A spray gun 43 is arranged at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com