Quantitative bidirectional powder spreading device and laser selective melting forming device thereof

A powder spreading device and powder spreading technology are applied in the fields of laser selective melting and forming device and quantitative two-way powder spreading device, which can solve the problems of increasing the movement stroke of the powder spreading arm, increasing the size of the forming equipment, reducing the stroke, etc., so as to shorten the atmosphere. The effect of preparation time, shortened forming time, and reduced motion stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

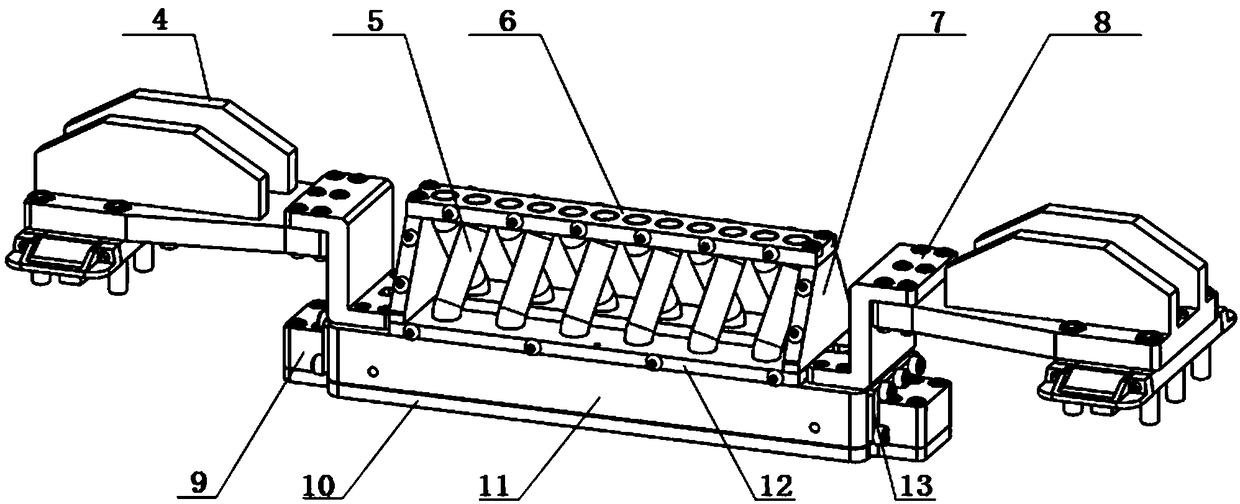

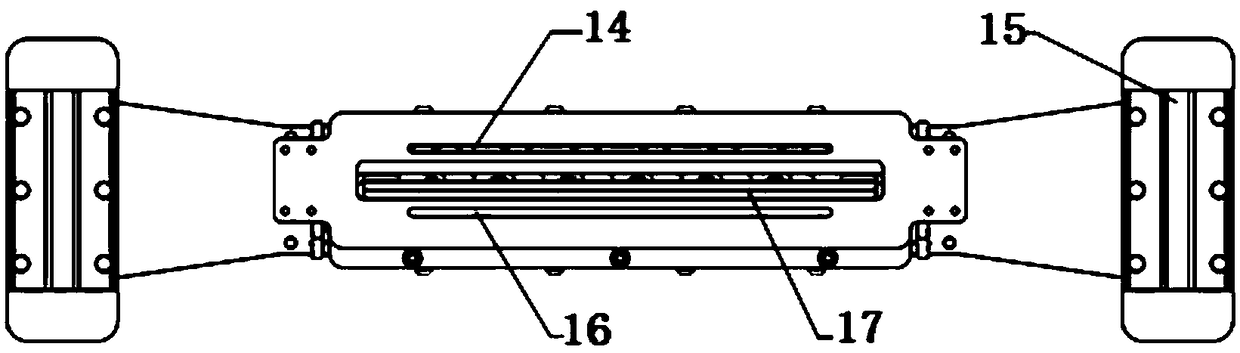

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] The invention provides a quantitative two-way powder spreading device, which comprises a powder spreading structure and a powder falling structure; the powder falling structure is arranged above the powder spreading structure.

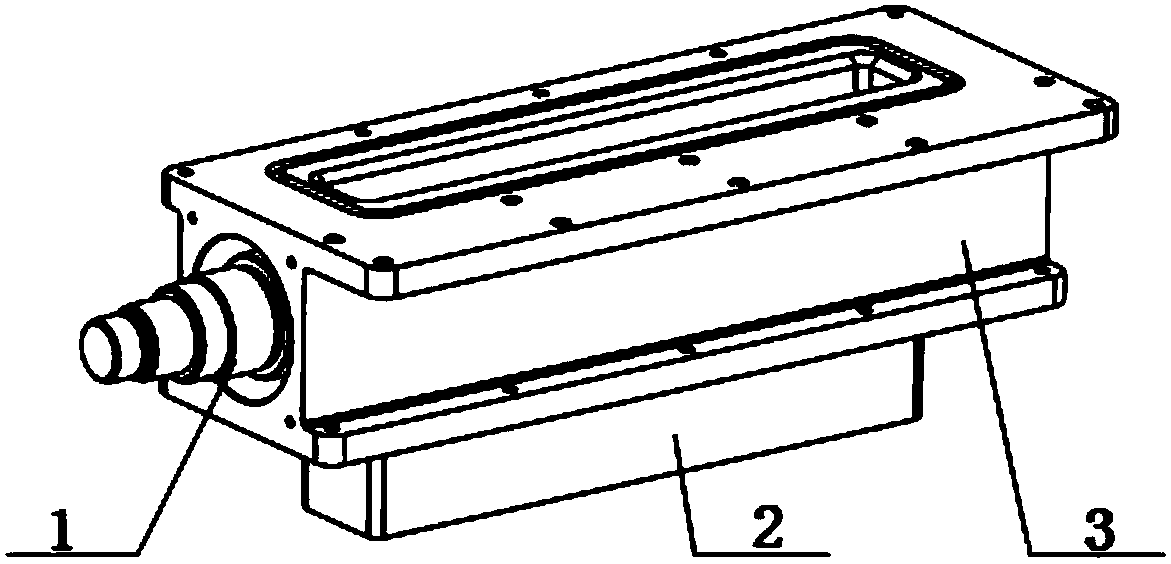

[0031] Such as image 3 As shown, the powder falling structure includes a powder falling chamber 3, and a powder falling shaft 1 is arranged in the powder falling chamber 3, and the powder falling shaft 1 can rotate in the powder falling chamber 3; specifically, the upper and lower parts of the powder falling chamber 3 are both An opening is provided, the upper opening is used to load powder, and the lower opening is used to drop powder to the powder spreading structure.

[0032] Preferably, the opening directly below the lower part of the powder falling chamber 3 is opposite to the ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com