A kind of cable insulating material and preparation method thereof

A cable insulation and compound technology, applied in the field of materials, can solve the problems of cumbersome and complicated cable preparation, and achieve the effects of good cross-linking environment, strong controllability, and improved self-healing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the ethanol-modified bone glue adhesive in the present invention comprises: mixing bone glue particles with water, raising the temperature to 60-65° C., adding sodium hydroxide, and lowering the temperature to 40° C. after stirring. Adjust the pH value to 6-7, add epichlorohydrin dropwise while stirring, and continue to react for 2 hours to obtain a liquid. Add ethanol to the above liquid at 30-40°C, and stir for 1 h.

[0022] The transition metal compound includes any one or at least two of oxides, hydroxides and salts of transition metals; preferably, the transition metals include at least one of Mn, Fe, Co, Ni, Cu, Sn and Ti. More preferably, the transition metal compounds are oxides, hydroxides and salts of Ni and Sn. Still more preferably, the transition metal compounds are nickel oxide and tin oxide.

[0023] The rare earth metal compound includes any one or at least two of oxides, hydroxides, and salts of rare earth metals; preferably,...

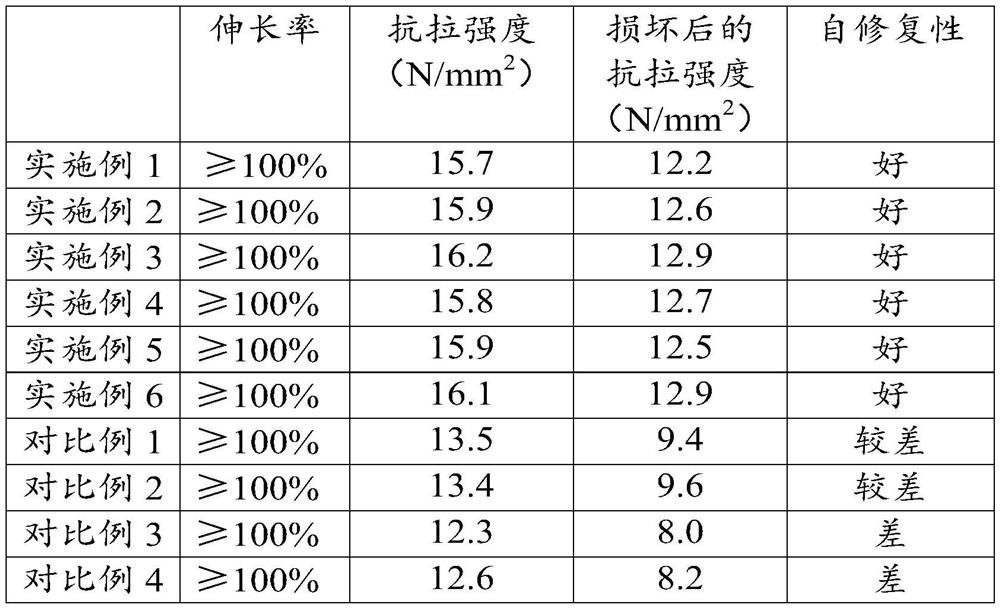

Embodiment 1

[0035] This embodiment provides a cable insulating material, which is prepared by the following preparation method:

[0036] Raw materials were weighed in proportion, 60 parts of butadiene-vinylpyridine rubber, 1 part of epichlorohydrin modified bone glue adhesive, 1 part of a mixture of copper sulfate and iron oxide, 0.5 parts of praseodymium oxide, and antioxidant BHT0.5 1 part, zinc oxide whisker 1 part. The transition metal compound and the rare earth metal compound have a particle size of 50 microns and a purity of 99%.

[0037] Mix and melt butadiene-vinylpyridine rubber and epichlorohydrin modified bone glue adhesive at 80°C for 2 minutes, add zinc oxide whiskers, mix and melt for 3 minutes, add antioxidant BHT, mix and melt for 5 minutes, and heat up to At 150°C, add a mixture of copper sulfate and iron oxide and praseodymium oxide to melt for 20 minutes. The mixed and molten mixture was stirred at a speed of 300 r / min for 0.5 h, and the viscosity was 60 Pa·s.

Embodiment 2

[0039] This embodiment provides a cable insulating material, which is prepared by the following preparation method:

[0040]Weigh raw materials in proportion, 100 parts of butadiene-vinylpyridine rubber, 15 parts of ethanol modified bone glue adhesive, 3 parts of a mixture of nickel oxide and tin oxide, 1.5 parts of a mixture of praseodymium oxide and praseodymium chloride, antioxidant 1.5 parts of BHT and dihydroquinoline, 5 parts of zinc oxide whiskers, and 1 part of flaky lignin fiber. The transition metal compound and the rare earth metal compound have a particle size of 0.1 micron and a purity of 99.999%.

[0041] Mix and melt butadiene-vinylpyridine rubber and ethanol-modified bone glue adhesive at 100°C for 8 minutes, add zinc oxide whiskers, mix and melt for 6 minutes, then add antioxidant BHT and dihydroquinoline, mix and melt for 10 minutes, Raise the temperature to 180°C, add nickel oxide, tin oxide, praseodymium oxide and praseodymium chloride to melt for 40 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com