Preparation method of insulating paper with acid-base durability and hydrophobic self-repairing function

An insulating paper and durability technology, applied in the field of power system and oil-paper insulation system inside power transformers, can solve the problems of hydrophobic surface damage, limited insulation life, insulation paper affecting mechanical properties and thermal stability performance, etc., to achieve resistance to physical Wear, surface energy reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

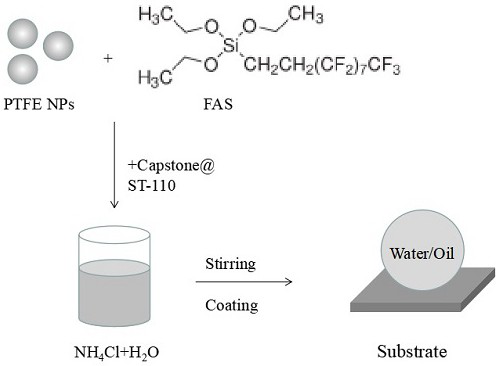

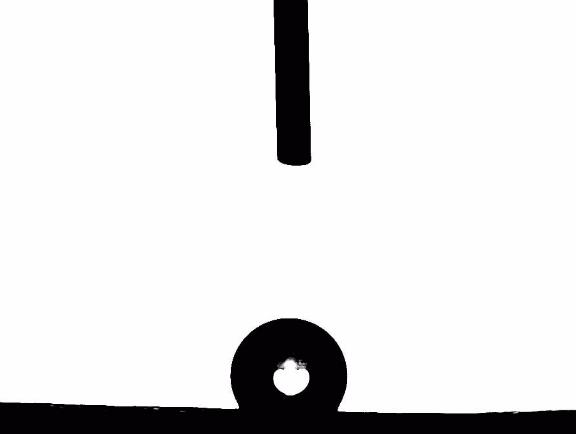

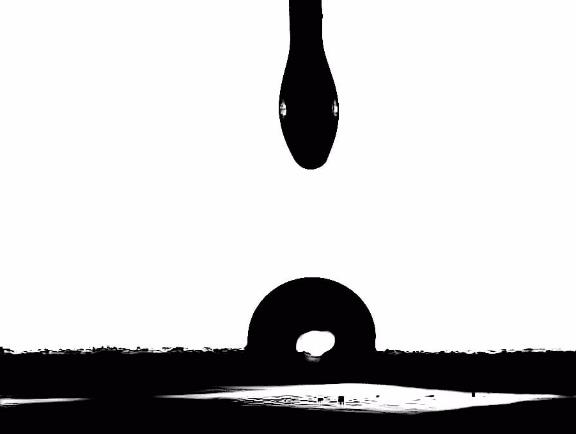

[0033] The 1 g of the polytetrafluoroethylene PTFE nanoparticles were proposed to 3.5 g of fluorocarbon surfactant ST-110, and then the fluorinated alkylsilane (FAS) 1.5 ml was added, and after preliminary mixing was dispersed, the magnetic stirrer was stirred for 20 min to form uniform Dispersions. To the dispersion, 2 g of ammonium chloride powder and a small amount of deionized water were added, and the aqueous coating solution was concentrated. To the concentrated suspension, 200 ml of deionized water was added, and the magnetic force was stirred for 30 min, a stable aqueous coating solution was obtained, and the no obvious precipitate was observed after 1 h. The insulating paper substrate was observed. The insulating paper was sprayed using a spray bottle, and the spray distance was 10 cm. When the substrate was 12 cm of insulating paper, the amount of solution was 50 ml; or the insulating paper was soaked directly in a coating solution for 5 minutes. After 20 min, after 20 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com