A passivation solution and method suitable for improving the corrosion resistance of hot-dip galvanized steel surfaces

A hot-dip galvanizing and corrosion-resistant technology, applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve problems such as unsatisfactory corrosion resistance, insufficient density of the film layer, and easy damage of the film layer. Achieve the effect of improving corrosion resistance, improving microscopic appearance, and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0022] The reagents used in the examples of the present invention are all commercially available.

[0023] The detection instrument used in the embodiment of the present invention comprises:

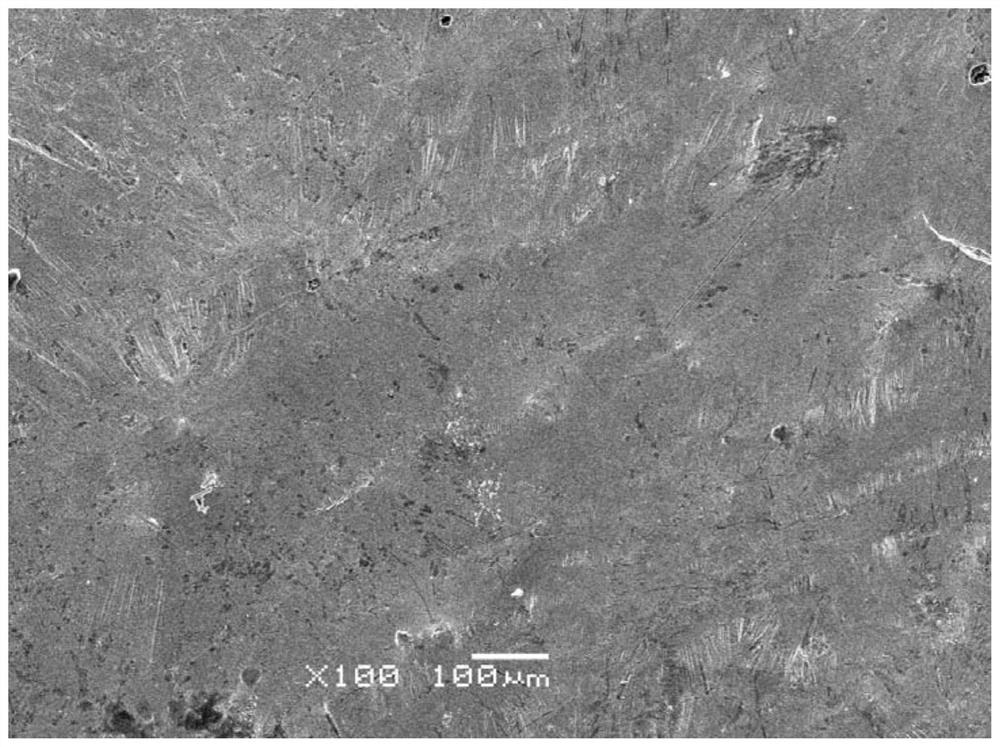

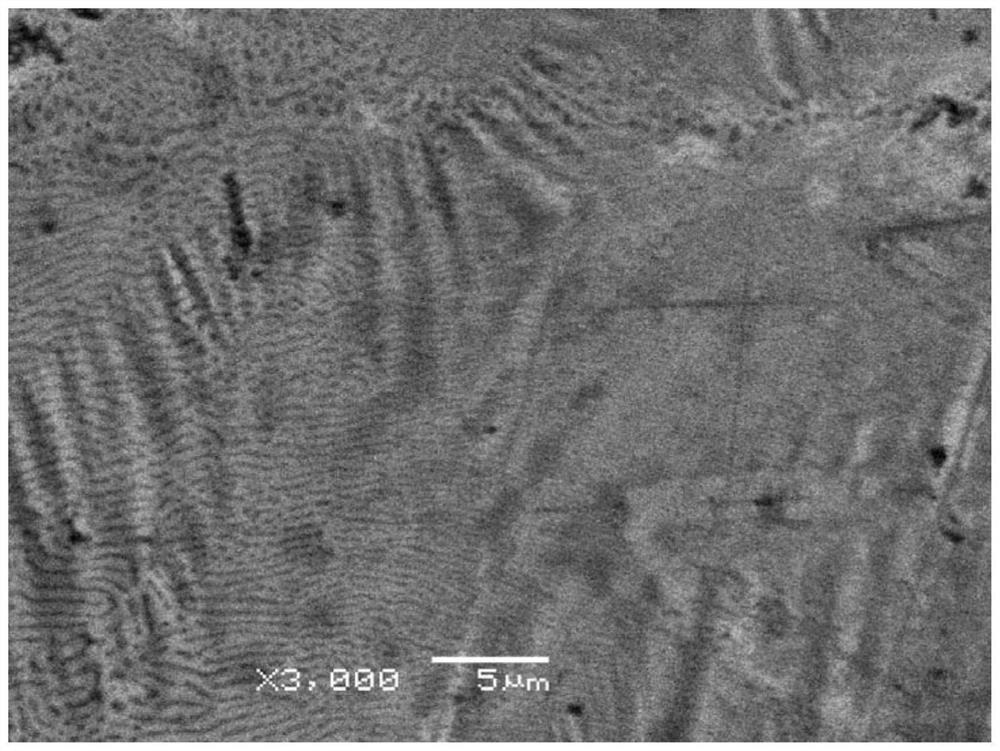

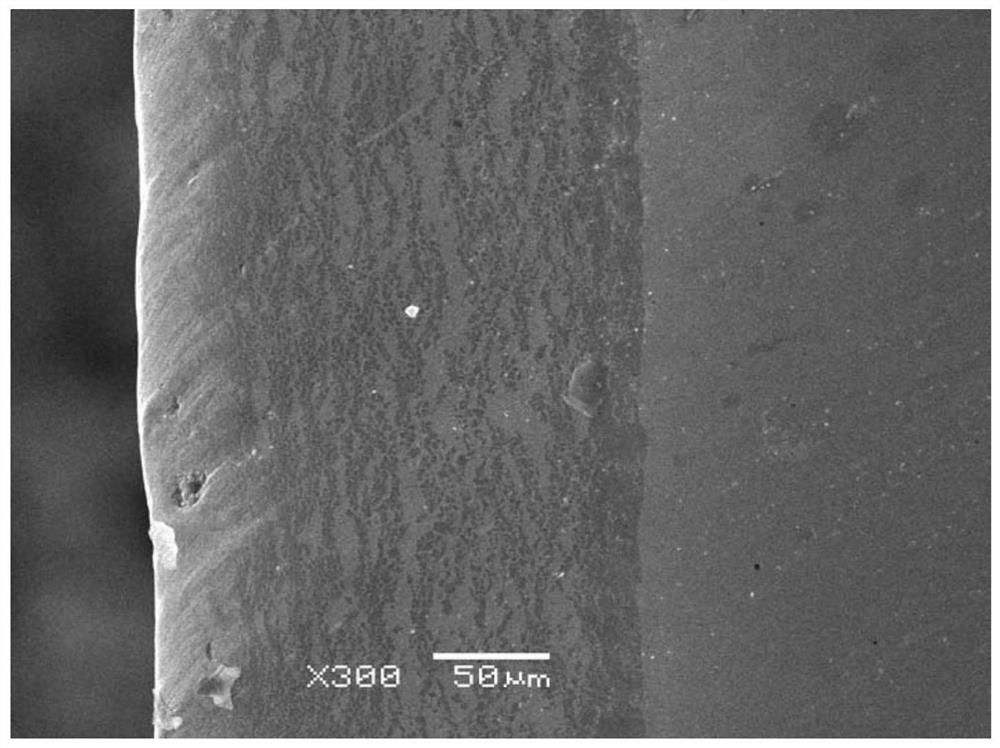

[0024] The scanning electron microscope model JSM-6360LV produced by Japan Co., Ltd.

[0025] A passivation solution suitable for improving the corrosion resistance of hot-dip galvanized steel surfaces, comprising the following components:

[0026] Titanium sulfate 13-17g / L, nickel sulfate 8-10g / L, propyltrimethylsilane 6-8g / L, nano-silicon carbide 0.05-0.15g / L, and the balance is deionized water.

[0027] A passivation method for improving the corrosion resistance of hot-dip galvanized steel surface, comprising the following steps:

[0028] S1, put the passivation solution into the passivation tank;

[0029] S2, adjusting the temperature (30-40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com