Titanium dioxide conversion coating liquid on aluminum alloy surface and its application method

A technology of aluminum alloy surface and titanium dioxide, applied in the direction of metal material coating process, etc., can solve the problems of process instability, large energy, pollution, etc., and achieve the effect of uniform color, excellent corrosion resistance and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Degrease the 5052 aluminum alloy with Turco4215NC-LT degreasing solution from Turco Products Inc. of the United States, and then immerse it in a NaOH solution with a temperature of 60-70 ° C and a mass content of 5-10% for 5 minutes;

[0027] Immerse the aluminum alloy after alkali washing in a nitric acid solution with a mass content of 5-10% at room temperature for 1-3 minutes, and then rinse it with deionized water;

[0028] (2) Soak the aluminum alloy after surface pretreatment in the titanium dioxide conversion coating solution on the aluminum alloy surface at 20°C for 1 minute, take it out, wash it and dry it in the air to form a conversion coating on the aluminum alloy surface.

[0029] The titania conversion coating liquid on the surface of the aluminum alloy is dissolved in 1 liter of water by dissolving 0.05 g of titanyl sulfate and 0.1 g of ammonium fluoride, and adjusting the pH of the conversion liquid to 3.5 with sulfuric acid.

[0030] The conversion ...

Embodiment 2

[0032] (1) The pretreatment steps are the same as in Example 1;

[0033] (2) Soak the aluminum alloy after surface pretreatment in the titanium dioxide conversion coating solution on the aluminum alloy surface at 20°C for 5 minutes, take it out, wash it and dry it in water, and form a conversion coating on the aluminum alloy surface.

[0034] The titania conversion coating liquid on the surface of the aluminum alloy is dissolved in 1 liter of water by dissolving 0.5 g of titanyl sulfate and 0.3 g of ammonium fluoride, and adjusting the pH of the conversion liquid to 4.0 with sulfuric acid.

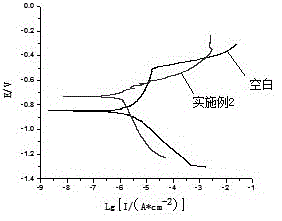

[0035] The conversion coating prepared in this example has a uniform color and does not corrode after 14 days of neutral salt spray test.

[0036] Such as figure 1 with figure 2 Shown, embodiment 2 transforms and processes sample and carries out scanning electron microscope SEM picture and EDS energy spectrum analysis result. The analysis results show that the conversion film has an am...

Embodiment 3

[0039] (1) The pretreatment steps are the same as in Example 1;

[0040] (2) Soak the aluminum alloy after surface pretreatment in the titanium dioxide conversion coating solution on the aluminum alloy surface at 20°C for 15 minutes, take it out, wash it and dry it in the air, and form a conversion coating on the aluminum alloy surface.

[0041] The titanium dioxide conversion coating solution on the surface of the aluminum alloy was dissolved in 1 liter of water with 1.0 g of titanyl nitrate and 0.8 g of potassium fluoride, and the pH of the conversion solution was adjusted to 4.5 with sulfuric acid.

[0042] The conversion coating prepared in this example has a uniform color and does not corrode in the neutral salt spray test for 9 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com