Antibacterial low-VOC (low-volatile organic compound) PBT (polybutylene terephthalate) composite material and preparation method thereof

A composite material and antibacterial agent technology, which is applied in the field of low VOC antibacterial PBT composite materials and its preparation, can solve the problems of unsatisfactory antibacterial performance and demand of PBT materials, achieve good VOC performance, excellent antibacterial performance, and improve VOC performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

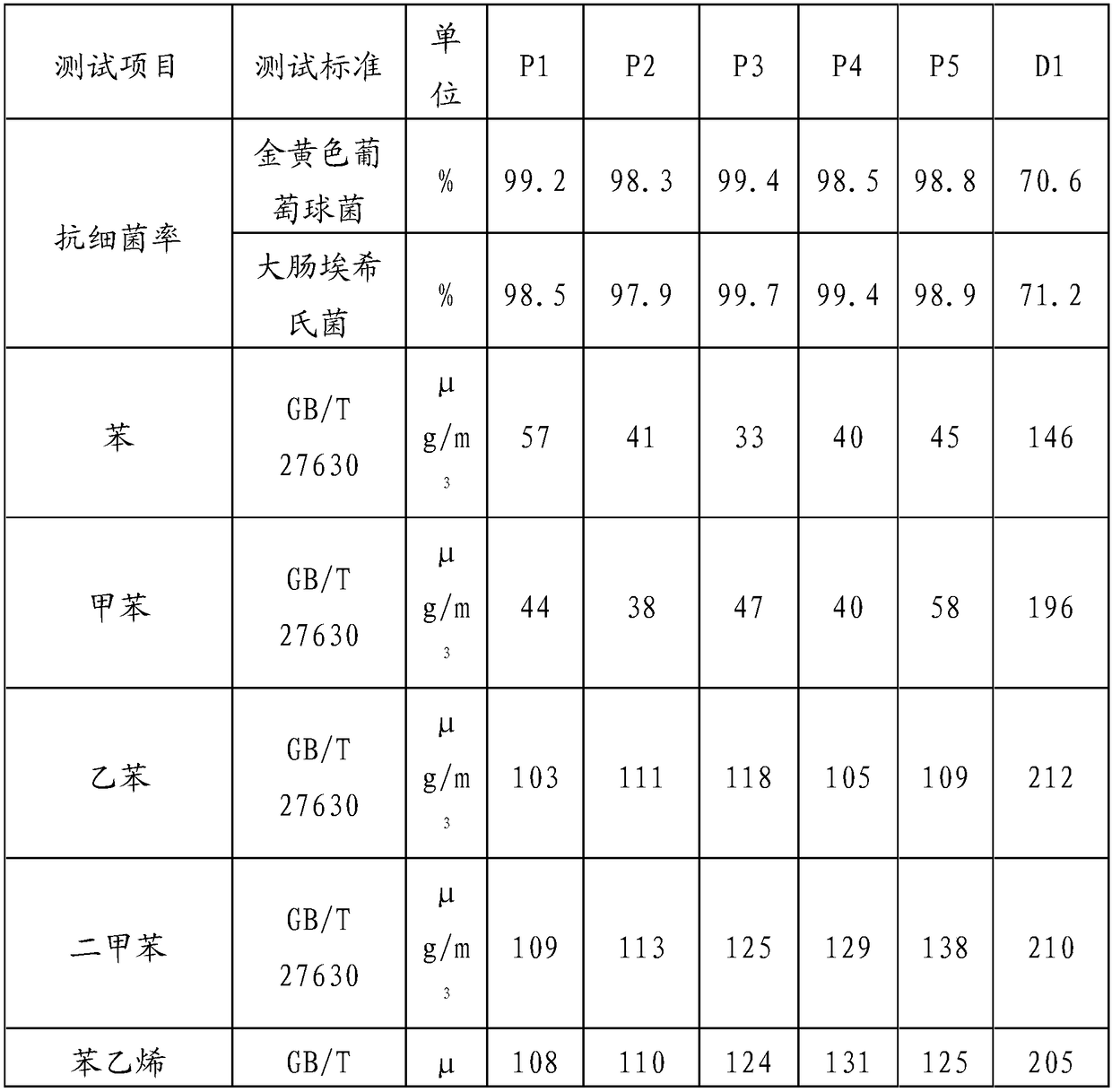

Examples

preparation example Construction

[0050] A preparation method of low-VOC antibacterial PBT composite material, comprising the following steps:

[0051] (1) Weigh 60-80 parts of PBT, 4-6 parts of antibacterial agent, 8-10 parts of VOC improved masterbatch, 0.1-0.5 part of antioxidant;

[0052] (2) extruding and granulating the mixture obtained in the step (1) to obtain the PBT composite material.

[0053] The twin-screw extruder in the step (2) includes six temperature zones arranged in sequence, the temperature in the first zone is 200-220°C, the temperature in the second zone is 240-260°C, the temperature in the third zone is 240-260°C, and the temperature in the fourth zone The temperature is 240-260°C, the temperature of the fifth zone is 240-260°C, the temperature of the sixth zone is 240-260°C, the temperature of the head is 240-260°C, and the screw speed is 200-280r / min.

Embodiment 1

[0055] (1) Weigh 60 parts of PBT, 4 parts of antibacterial agent, 8 parts of VOC modified masterbatch, and 0.1 part of Irganox1010;

[0056] (2) Extrude and granulate the mixture obtained in the step (1) to obtain the PBT composite material P1.

[0057] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively; the temperature of the first zone is 200°C, the temperature of the second zone is 240°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 240°C, the temperature of the fifth zone is 240°C, the temperature of the sixth zone is 240°C, The head temperature is 240°C, and the screw speed is 200r / min.

Embodiment 2

[0059] (1) Weigh 80 parts of PBT, 6 parts of antibacterial agent, 10 parts of VOC modified masterbatch, 0.2 part of Irganox1010, 0.2 part of Irganox1330, 0.1 part of Irganox168;

[0060] (2) Extrude and granulate the mixture obtained in the step (1) to obtain the PBT composite material P2.

[0061] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively; the temperature of the first zone is 220°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 260°C, the temperature of the sixth zone is 260°C, The head temperature is 260°C, and the screw speed is 280r / min.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap