High-phosphorus IF (Interstitial-Free) steel and smelting method thereof

A smelting method and high phosphorus technology, applied in the field of iron and steel smelting, can solve problems such as poor cleanliness of molten steel, achieve the effects of reduced defect rate of rolled products, obvious economic benefits, and reduced liquid level fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for smelting high-phosphorus IF steel, comprising converter smelting, RH refining and continuous casting; its concrete steps are as follows:

[0017] Step 1), adding 250t of desulfurized molten iron into the converter for smelting, the temperature at the end of the converter is 1720°C, the C content is 0.025wt%, the O content is 790ppm, and the P content is 0.04wt%;

[0018] In step 2), when 1 / 3 of the molten steel smelted in step 1) is tapped from the converter, 1200kg of lime is added to the ladle, and the bottom blowing argon gas is turned on simultaneously during the tapping process, and after the tapping is completed, pour the slag into the ladle Add 600kg of aluminum slag to the surface to modify the ladle slag;

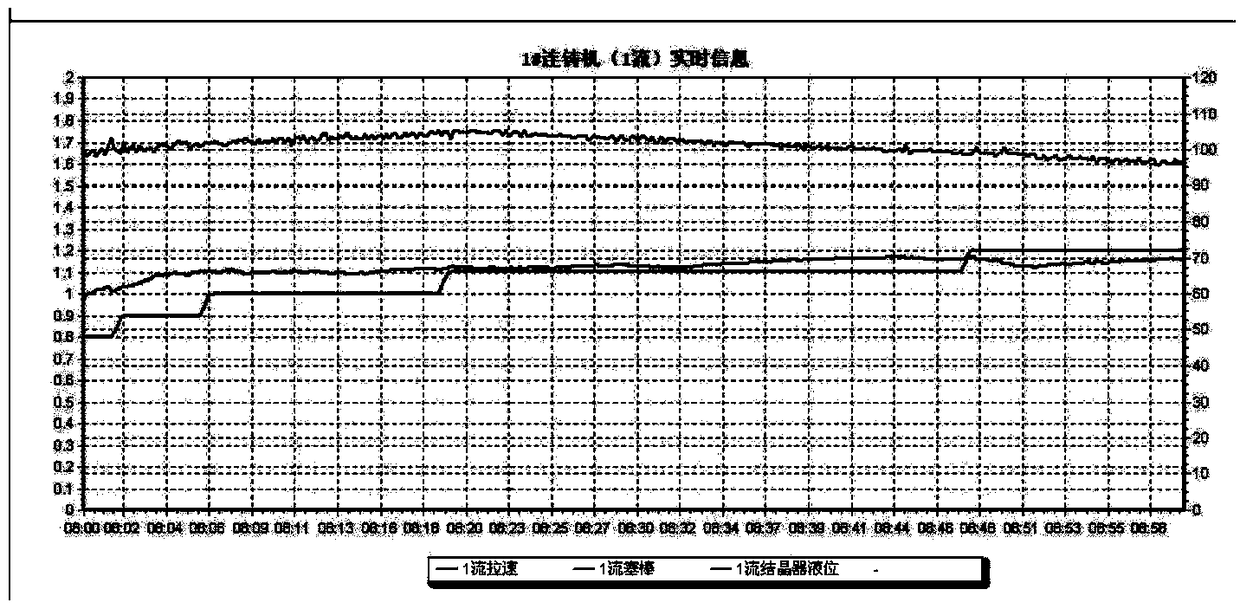

[0019] Step 3), T.Fe=7.8% in the slag when RH enters the station; Carry out RH refining, vacuum decarburization treatment, add carbon ferromanganese and phosphorus ferromanganese in the first 10 minutes of decarburization treatment to roughly ad...

Embodiment 2

[0023] A method for smelting high-phosphorus IF steel, comprising converter smelting, RH refining and continuous casting; its concrete steps are as follows:

[0024] Step 1), adding 250t of desulfurized molten iron into the converter for smelting, and controlling the temperature at the end point of the converter to be 1710°C, the content of C: 0.030wt%, the content of O: 703ppm, and the content of P: ≤0.03wt%;

[0025] Step 2), when 1 / 3 of the molten steel smelted in step 1) is tapped from the converter, 1000kg of lime is added to the ladle, and the bottom blowing argon gas is turned on at the same time to stir during the tapping process. Add 500kg of aluminum slag to the surface to modify the ladle slag;

[0026] Step 3), when RH enters the station, T.Fe=5.0% in the slag; carry out RH refining, vacuum decarburization treatment, and add carbon ferromanganese and phosphorus ferromanganese within 10 minutes of decarburization treatment to roughly adjust the composition of molten...

Embodiment 3

[0030] A method for smelting high-phosphorus IF steel, comprising converter smelting, RH refining and continuous casting; its concrete steps are as follows:

[0031] Step 1), adding 250t of desulfurized molten iron into the converter for smelting, the temperature at the end of the converter is 1716°C, the C content is 0.031wt%, the O content is 600ppm, and the P content is 0.03wt%;

[0032] Step 2), when 1 / 3 of the molten steel smelted in step 1) is tapped from the converter, 800kg of lime is added to the ladle, and the bottom blowing argon gas is turned on simultaneously during the tapping process to stir. Add 400kg of aluminum slag to the surface to modify the ladle slag;

[0033] Step 3), when RH enters the station, T.Fe=4.8% in the slag; carry out RH refining, vacuum decarburization treatment, add carbon ferromanganese and phosphorus ferromanganese in the first 10 minutes of decarburization treatment to roughly adjust the molten steel composition, After 17 minutes of vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com