Device and method for unbinding flat target material and rotary target material

A technology of rotating target and flat target, which is applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of unsuitable target material, achieve the goal of intact target material, convenient collection of residual indium, and uniform heating temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

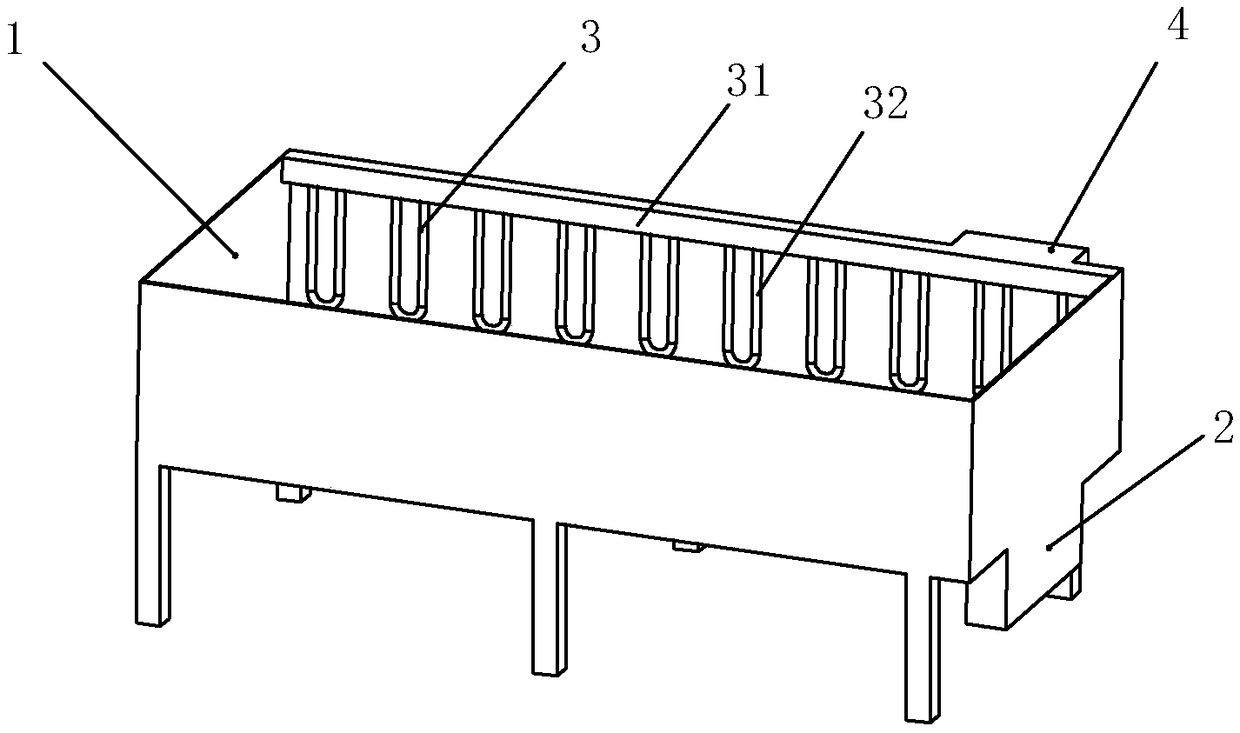

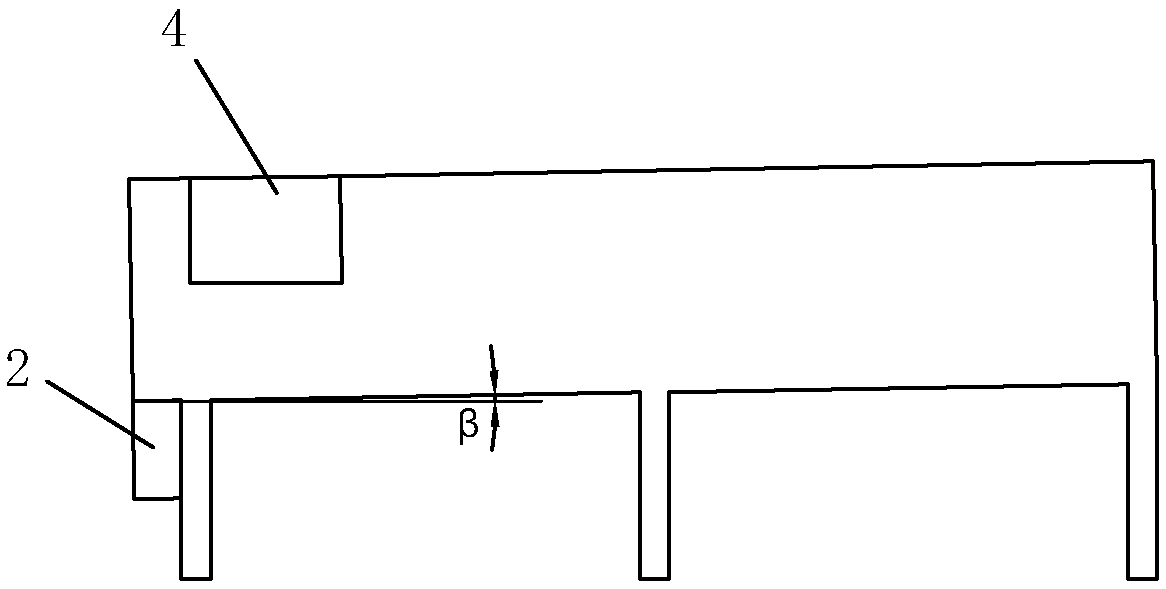

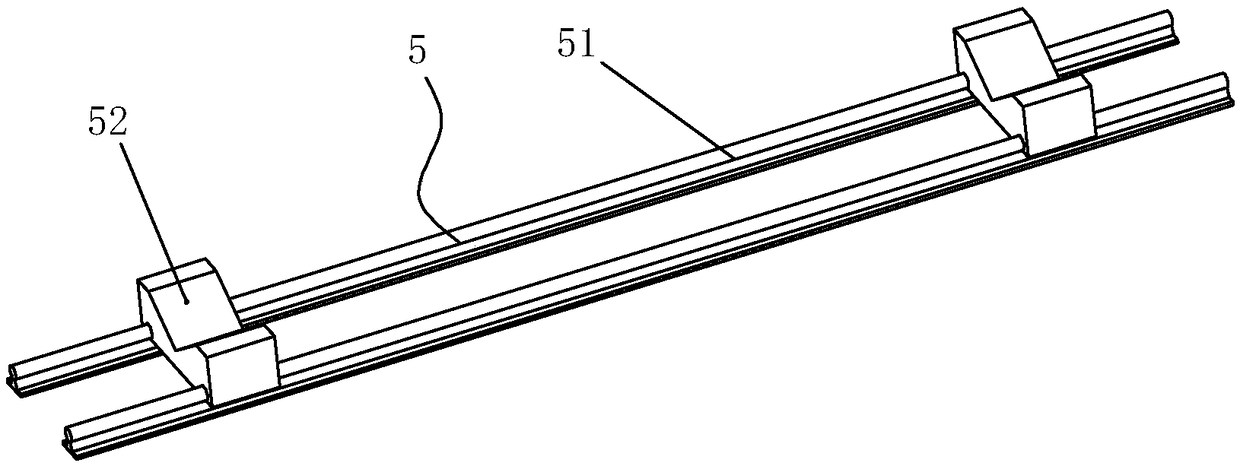

[0029] Example 1: A device for planar and rotating target unbinding, such as Figure 1-Figure 8 As shown, it includes an oil bath 1, a heating assembly 3, a planar target grid bracket 6, a rotating target bracket 5 and an indium collection basket 7. The bottom surface of the oil bath is inclined, and there is a collection The indium basket is placed in the groove 2, the indium collection basket 7 is placed in the indium basket placement groove 2, and the heating assembly 3 is composed of a connecting rod 31 and a plurality of heating rods 32 evenly installed on the connecting rod. The heating rod is a U-shaped heating tube, and the heating assembly 3 is installed in the oil bath 1. The planar target grid bracket 6 includes a plurality of partitions 61 with small holes thereon, and the plurality of partitions are separated by a certain distance. Arranged obliquely, the upper and lower ends on both sides of the plurality of partitions are connected by an upper link 62 and a lowe...

Embodiment 2

[0033] Embodiment 2: A method for unbinding a plane and a rotating target, using the device for unbinding a plane and a rotating target described in Embodiment 1, comprising the following steps:

[0034] (1) Select the planar target grid bracket or rotating target bracket to be used according to the target type that needs to be unbound;

[0035] (2) There are two operation methods; method 1: put the planar target grid bracket or rotating target bracket into the oil bath first, and then add oil bath oil to the oil bath; method 2: first add oil to the oil bath Add oil bath oil into the bath, and then put the planar target grid bracket or rotating target bracket into the oil bath;

[0036] (3) Heat the oil bath oil to 170°C-250°C;

[0037] ⑷ Place the planar or rotating target bound with indium metal to be unbound and the back plate pasted together with the target on the corresponding bracket. After the indium melts, the separated target and back plate can be placed Take out se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com