Air compressor group optimization scheduling method based on hybrid model

A technology of optimal scheduling and hybrid model, applied in the field of information, can solve problems such as difficulty in realization and difficulty in opening and combining of air compressors, and achieve the effect of reducing costs, shortening formulation time, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

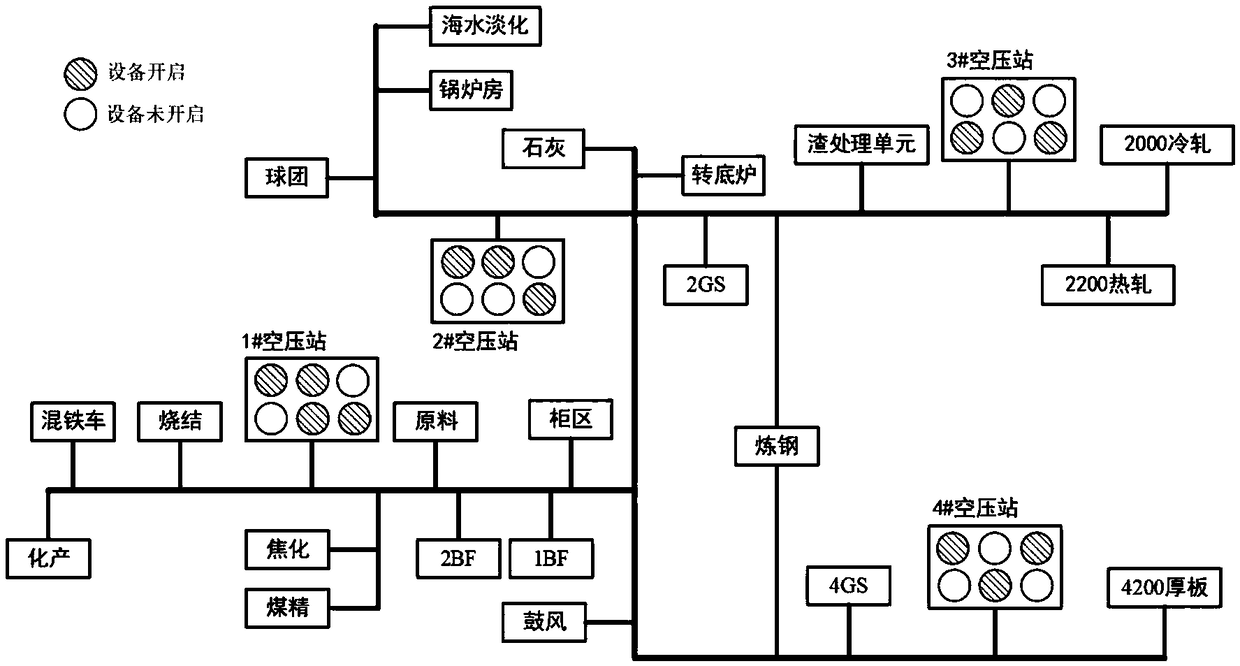

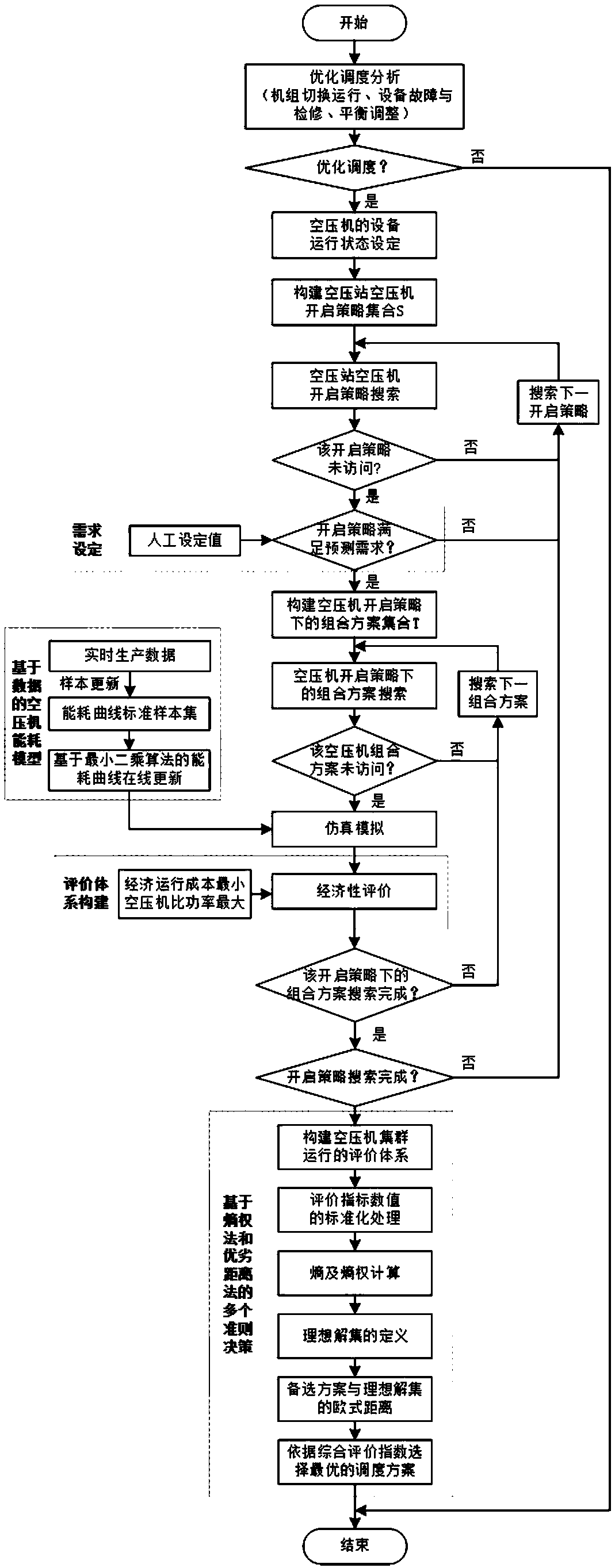

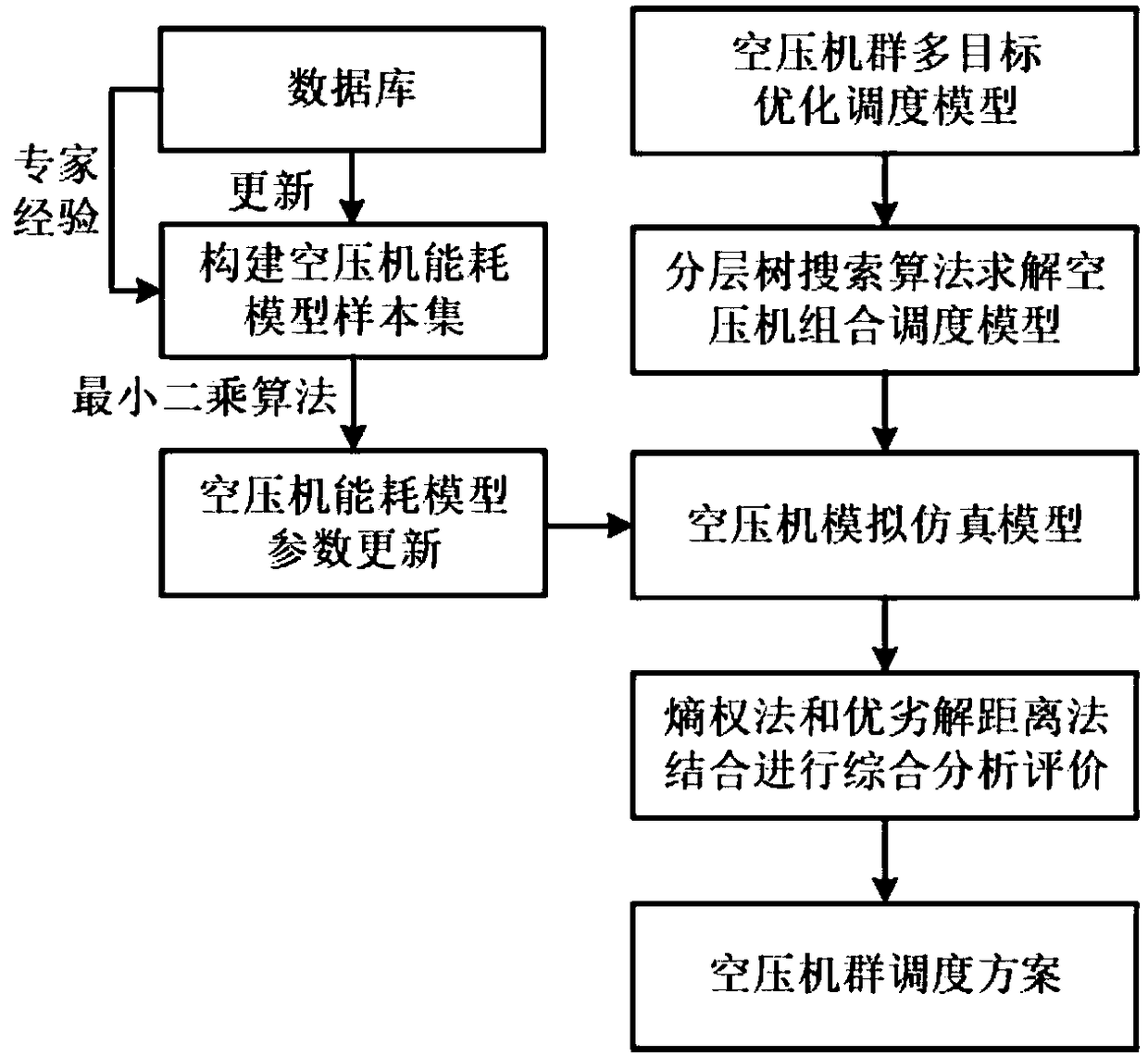

[0017] In order to better understand the technical solution of the present invention, the present invention takes the group scheduling of air compressors in metallurgical enterprises as an example, combined with the attached figure 2 Embodiments of the present invention are described in detail.

[0018] A hybrid model-based air compressor group optimal scheduling method, the steps are as follows:

[0019] Step 1: Construction of sample set of air compressor energy consumption model

[0020] Obtain the intake flow, output flow, motor current and outlet exhaust pressure of the j air compressor of the i-th air compressor station for a period of time from the database; select some samples from the above-mentioned time period according to experience, and construct the air The initial sample set of the compressor energy consumption model; the sample set of each air compressor in different air compressor stations is initialized sequentially;

[0021] Step 2: Air compressor energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com