Preparation method of adjustable waveguide system for X-ray nano-scale focusing

An adjustable, nano-scale technology, applied in radiation/particle processing, application of diffraction/refraction/reflection processing, nuclear engineering, etc., can solve the problem of distance and difference between the fixed gap and the inability to accurately locate the focal length, so as to make up for the focus The effect of performance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

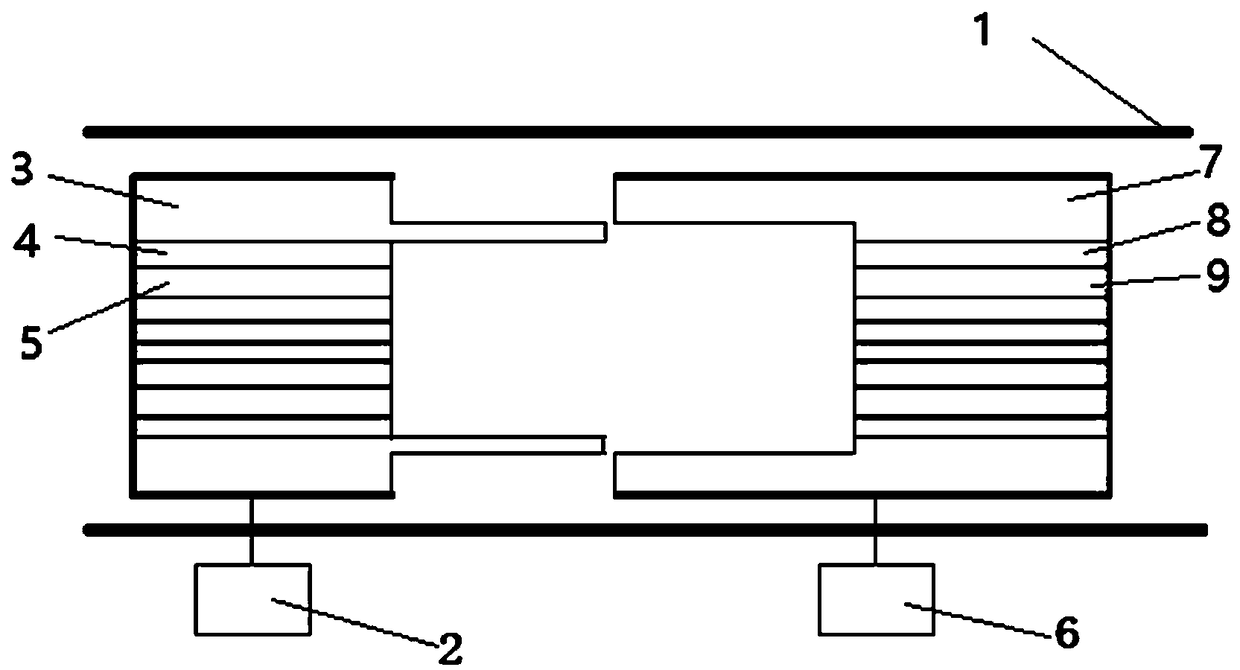

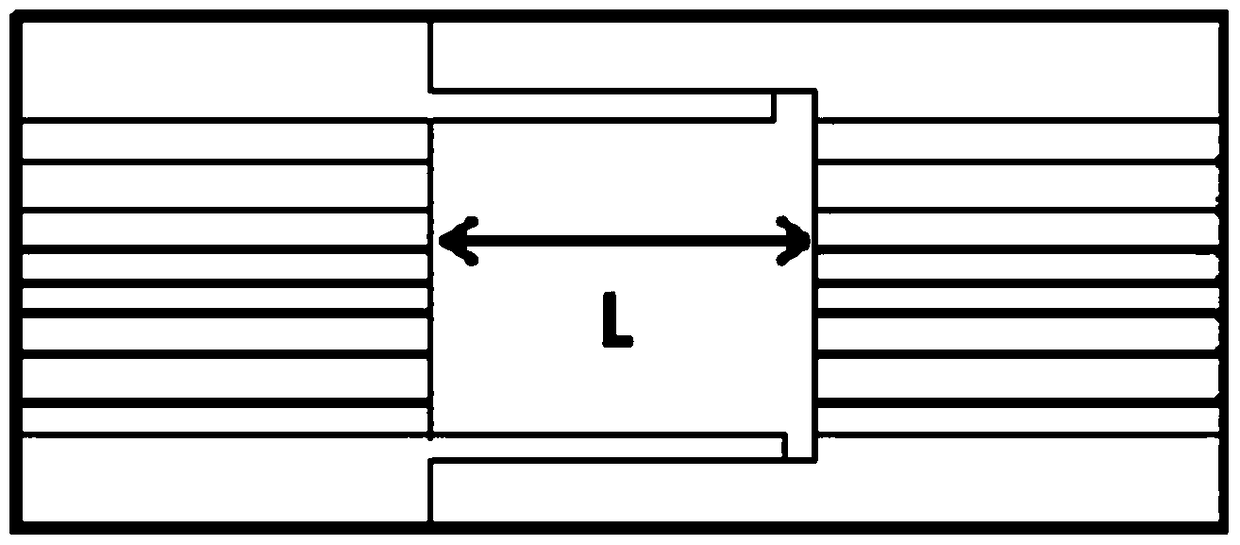

[0022]The present invention will be further described below in conjunction with the accompanying drawings. As the background technology belongs, the principle of the structure and method of the multilayer film waveguide itself is very clear to those skilled in the art. The specific implementation methods of this application only focus on the prior art In addition, it should be noted that the structures in the drawings of the description are only schematic in nature, for example, the number of film layers in the figure is not the real number of layers, as mentioned in the background technology, the number of film layers is actually generally The base number, the middle layer is the conduction layer, and the two sides are the spacer layer, the conduction layer, the spacer layer, etc., and so on. At present, 3-15 layers are mentioned in the prior art. In the embodiment, the waveguide structure of 15 layers is used. To illustrate, in fact, no matter how many layers of the waveguide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com