A low-temperature green processing production line and method for stewing meat products with sauce

A technology for stewed meat products and production lines, which is applied in climate change adaptation, food science, etc., can solve the problems of increased initial bacteria of products to be sterilized, increased energy consumption, and affecting the sterilization effect, so as to save labor costs and site costs, High production efficiency, guaranteed nutritional value and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

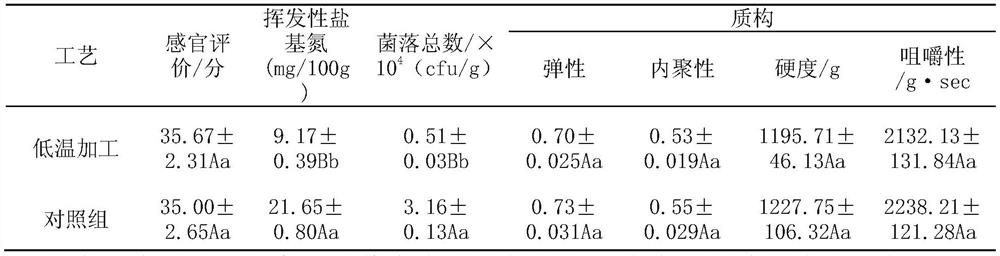

[0024] The general idea of the present invention is to use partial vacuum stewing to replace room temperature stewing, vacuum rapid cooling to replace normal temperature or ordinary cold storage to cool down, use a hundred-level laminar flow hood to create a sterile environment, and use vacuum packaging in a sterile environment to reduce product pollution as much as possible , and then use temperature-coordinated ultrasonic pasteurization to achieve the purpose of low-temperature sterilization, and then use a cold air dryer to cool the product and dry the outer packaging.

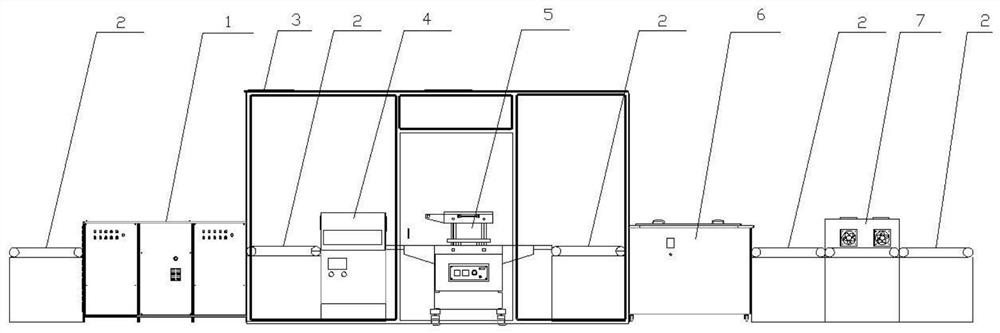

[0025] Such as figure 1 A low-temperature green processing line for stewed meat products with sauce shown, including a stewed curing unit, an aseptic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com