A titanium vacuum metal thermos cup and a manufacturing method thereof

A technology of vacuum heat preservation and production method, which is applied in the direction of drinking water vessels, etc., can solve the problems of poor surface quality and low vacuum sealing yield of titanium metal thermos cups, and achieve the effect of stable quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The making of embodiment 1 titanium metal vacuum insulation cup

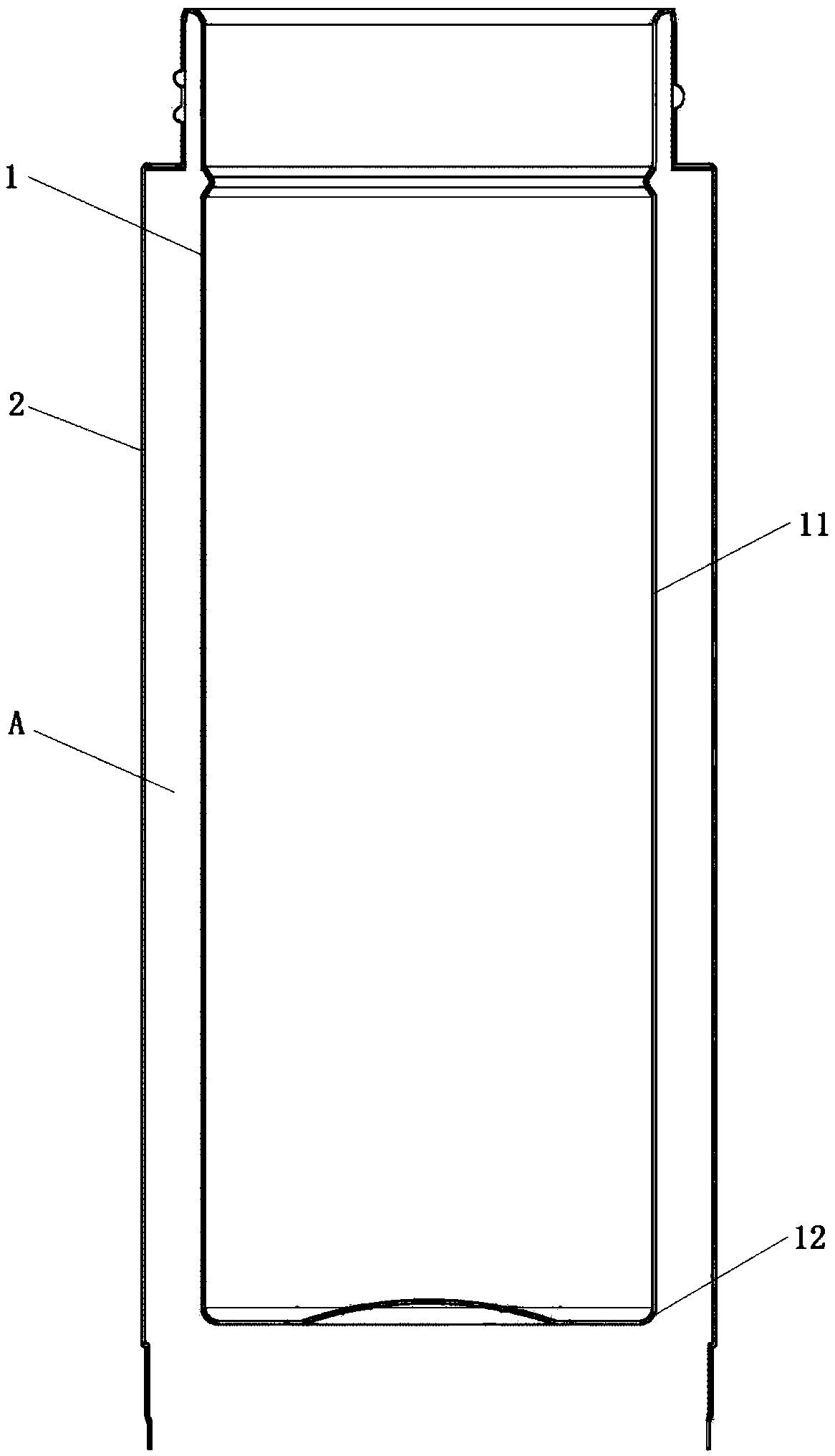

[0042] (1) Production of double-layer titanium metal semi-finished cup body: select titanium metal pipes with different diameters according to the design requirements, cut and blank, and use water expansion to obtain the outer shell 2 and bottomless liner cylinder 12 respectively; The inner tank bottom 11 that matches the whole body of the inner tank is obtained; the inner tank bottom 11 is butt-welded with the inner tank cylinder body 12 by laser welding and argon protection on both sides; according to the design requirements, the shell 2 and liner 1 are tightly matched at the mouth and connected by argon arc welding.

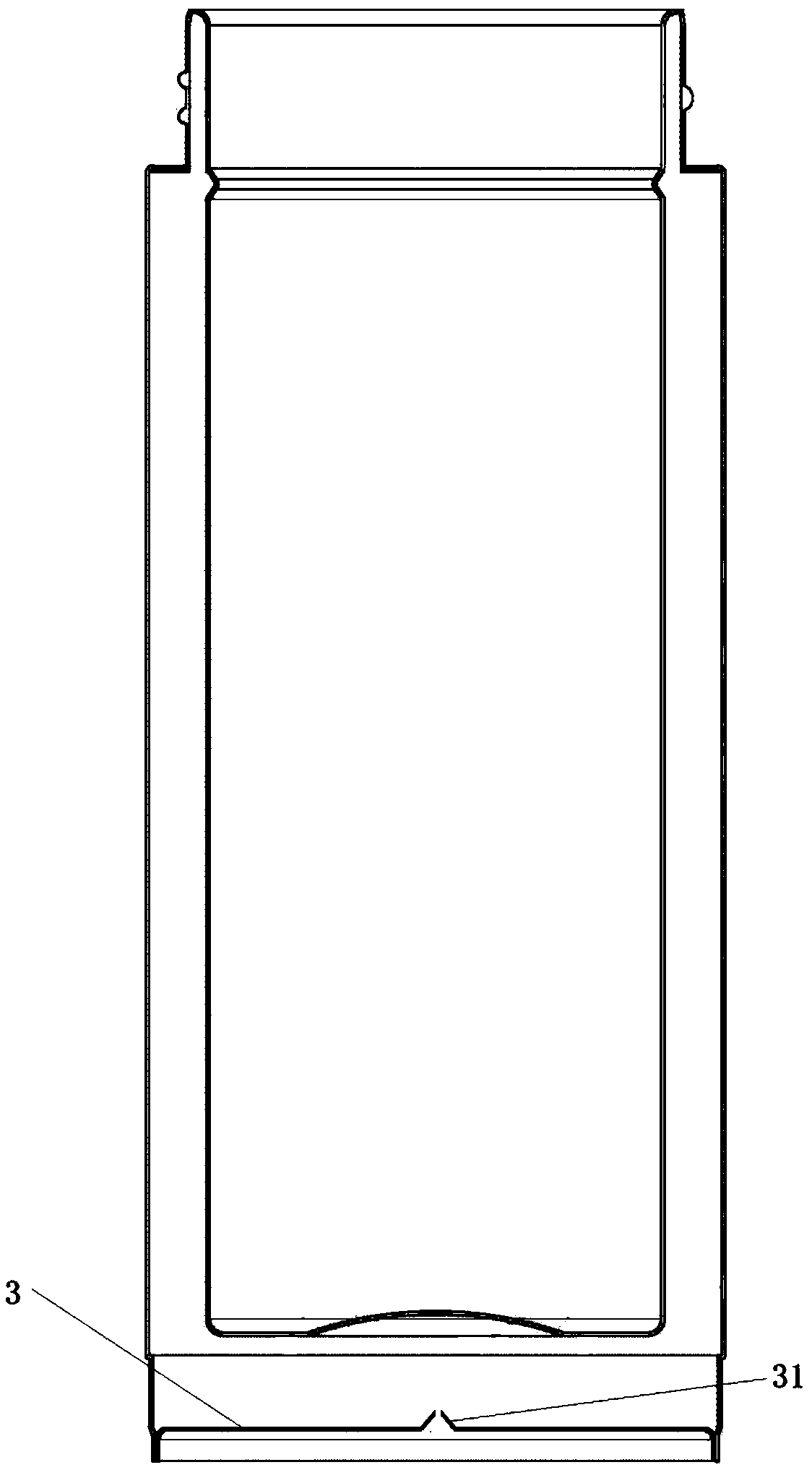

[0043] (2) Closure production: According to the design requirements, the titanium metal strip is blanked and stamped to make a back cover 3 matching the bottom of the shell 2, and punched at the center of the back cover to make a vacuum-tight through hole 31.

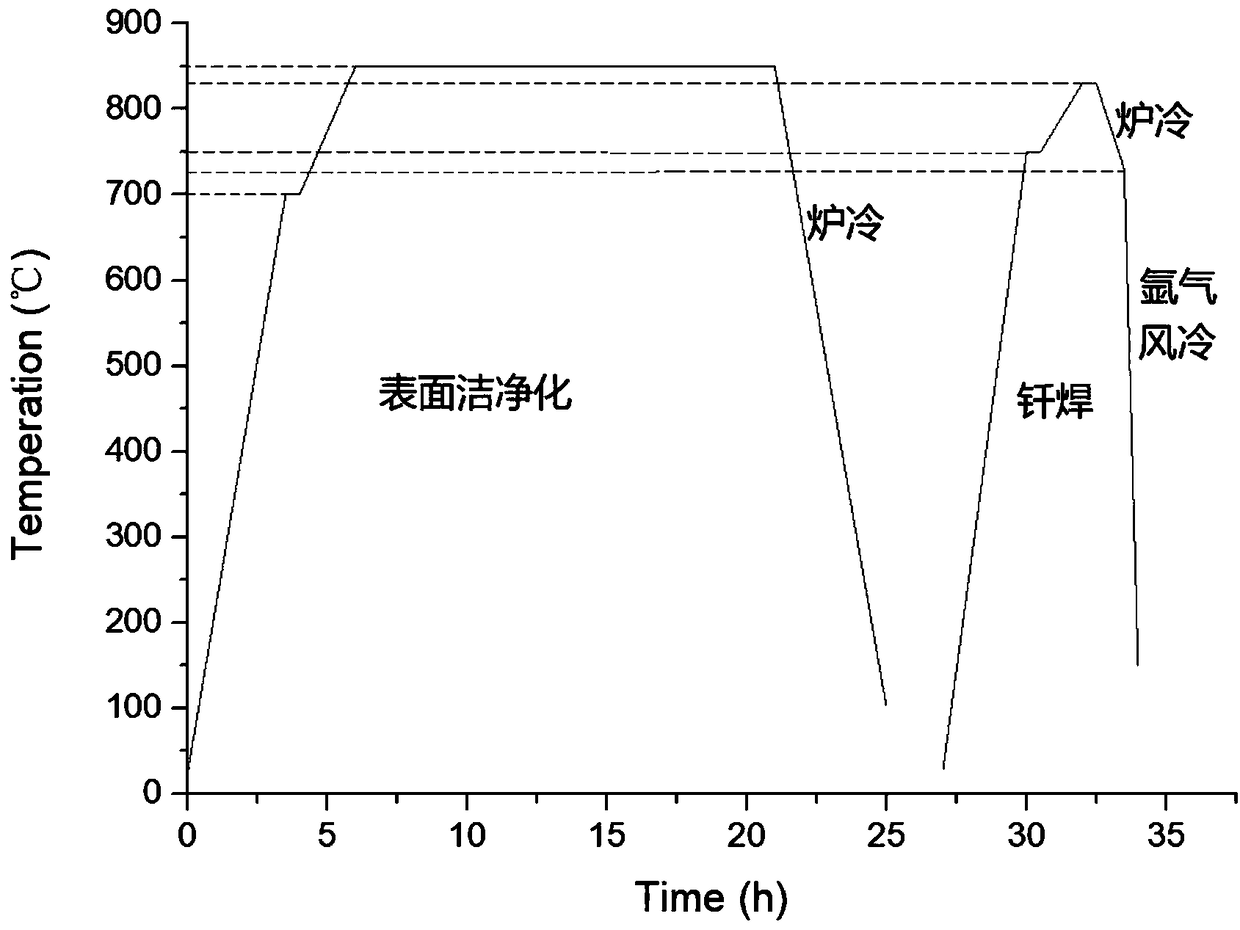

[0044] (3) Surface purific...

Embodiment 2

[0048] The making of embodiment 2 titanium metal vacuum insulation cup

[0049] (1) Same as embodiment one step (1).

[0050] (2) Same as embodiment one step (2).

[0051] (3) Surface purification pretreatment: Put the back cover 3 into a vacuum furnace and vacuumize to 9×10 -3 Pa, heat up to 750°C in 120 minutes, pass in argon, maintain the pressure in the furnace at 10-50Pa, keep warm for 30min, then raise the temperature to 930°C, keep warm for 6h, and cool to 80°C with the furnace.

[0052] (4) Welding back cover: pressing and tightly fitting the shell 2 and the back cover 3, and adopting argon arc welding to weld the connection to make a double-layer titanium metal cup body;

[0053] (5) Brazing and sealing: use Ag-28Cu silver-based solder to cover the brazing hole 31, put it in a vacuum furnace, raise the temperature to 750°C within 120min and keep it warm for 30min, then raise the temperature to 880°C for 60min and braze and seal for 10min; Cool the furnace to 730°C,...

Embodiment 3

[0055] The making of embodiment 3 titanium metal vacuum insulation cup

[0056] (1) Same as embodiment one step (1).

[0057] (2) Same as embodiment one step (2).

[0058] (3) Surface purification pretreatment: Put the back cover 3 into a vacuum furnace and vacuumize to 9×10 -3 Pa, heat up to 700°C in 100 minutes, pass in argon, maintain the pressure in the furnace at 50-80Pa, keep warm for 30 minutes, then raise the temperature to 1100°C, keep warm for 1 hour, and cool to 60°C with the furnace.

[0059] (4) Welding back cover: pressing and tightly fitting the shell 2 and the back cover 3, and adopting argon arc welding to weld the connection to make a double-layer titanium metal cup body;

[0060] (5) Brazing seal: Use HSGB-1 glass solder (softening point 325°C), cover the brazing hole 31, put it in a vacuum furnace, heat up to 300°C within 60 minutes, keep it warm for 30 minutes, and then heat up to 500°C for 60 minutes to braze Weld and seal for 30 minutes; cool to 300°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com