Method and application for improving sustained release properties of activated carbon on essence

A slow-release performance, activated carbon technology, applied in applications, essential oils/fragrance, chemical instruments and methods, etc., can solve the problems of poor reproducibility, poor desorption sustained-release effect, etc., to increase adsorption capacity and desorption capacity, Good sustained release effect and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

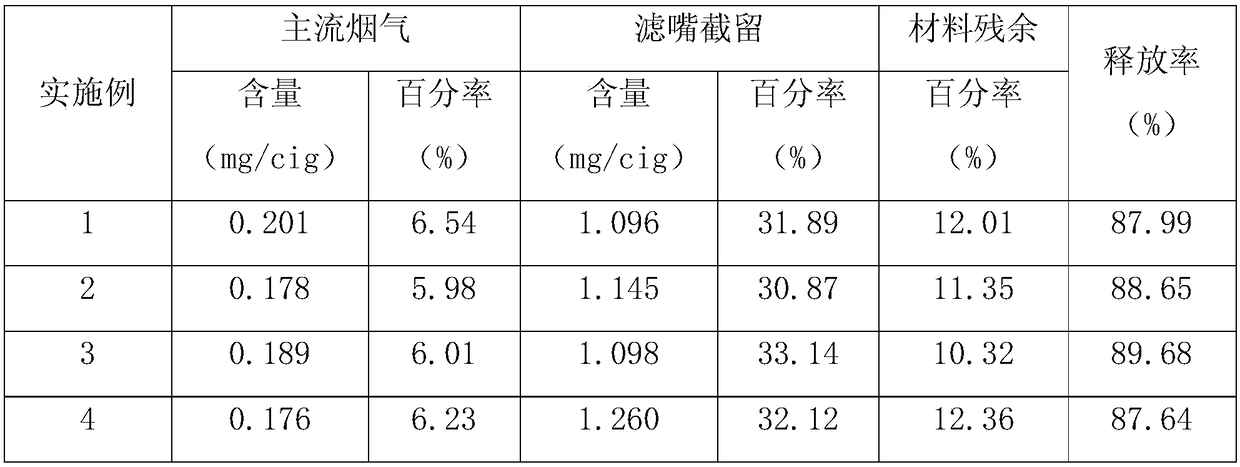

Embodiment 1

[0033] (1) Preparation of carbon quantum dots: 0.2 g of urea phosphate, 0.3 g of citric acid and 0.8 mL of ethylenediamine were dissolved in 25 mL of deionized water. Then the above solution was transferred to a microwave digestion tank, sealed and placed in a microwave digestion apparatus. The temperature program was set as follows: the reaction temperature was raised to 150° C. within 1 min, and the temperature was kept constant for 30 min. After cooling to room temperature, the obtained clear and transparent solution was centrifuged at 10,000 rpm for 15 minutes, and the supernatant was dried in a vacuum oven at 60° C. for 12 hours to obtain the product.

[0034] (2) Acidified activated carbon: Take 100g of activated carbon, soak it in 300mL 0.1mol / L HCl solution for 2h, place it in a water bath at room temperature and shake it for 12h, rinse with distilled water until the surface of the activated carbon is neutral, carry out suction filtration, and dry at 100°C for 3h, name...

Embodiment 2

[0038] (1) Preparation of carbon quantum dots: 0.5 g of urea phosphate, 0.6 g of citric acid and 0.9 mL of ethylenediamine were dissolved in 50 mL of deionized water. Then the above solution was transferred to a microwave digestion tank, sealed and placed in a microwave digestion apparatus. The temperature program was set as follows: the reaction temperature was raised to 150° C. within 1 min, and the temperature was kept constant for 30 min. After cooling to room temperature, the obtained clear and transparent solution was centrifuged at 10,000 rpm for 15 minutes, and the supernatant was dried in a vacuum oven at 60° C. for 24 hours to obtain the product.

[0039] (2) Acidified activated carbon: Take 100g of activated carbon and add it to 400mL 0.1mol / L HNO 3 After soaking in the solution for 2 hours, shake it in a water bath at room temperature for 20 hours, rinse with distilled water until the surface of the activated carbon is neutral, perform suction filtration, and dry ...

Embodiment 3

[0043](1) Preparation of carbon quantum dots: 0.4 g of urea phosphate, 0.5 g of citric acid and 1.0 mL of ethylenediamine were dissolved in 40 mL of deionized water. Then the above solution was transferred to a microwave digestion tank, sealed and placed in a microwave digestion apparatus. The temperature program was set as follows: the reaction temperature was raised to 150° C. within 1 min, and the temperature was kept constant for 30 min. After cooling to room temperature, the obtained clear and transparent solution was centrifuged at 10,000 rpm for 15 minutes, and the supernatant was dried in a vacuum oven at 60° C. for 20 hours to obtain the product.

[0044] (2) Acidified activated carbon: Take 100g of activated carbon and add 0.1mol / L HNO to 500mL 3 After soaking in the solution for 2 hours, shake in a water bath at room temperature for 15 hours, rinse with distilled water until the surface of the activated carbon is neutral, perform suction filtration, and dry at 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com