Metal organic framework and its preparation method and application

A metal-organic framework and reaction technology, which is applied in the field of compounds and their preparation, can solve the problems such as the decrease of the specific surface area and pore size of the adsorbent, the influence of the adsorption and desulfurization performance, and the blockage of the pores, so as to enhance the desulfurization adsorption performance, improve the adsorption and desulfurization performance, and the pore size Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of metal-organic frameworks

[0041] Mix copper chloride dihydrate and trimesic acid in 500mL polytetrafluoroethylene liner, stir at room temperature for 5 hours, add N,N-dimethylacetamide, the molar ratio of the three is 2:1:0.1, and stir Mix evenly until all the solids are dissolved, put the liner into the autoclave, react at 100°C for 48 hours to obtain the reaction mother liquor, after cooling to room temperature, filter and wash with ethanol, and dry in vacuum to obtain Cu-BTC-DMA;

[0042] Under light-shielded conditions, dissolve Cu-BTC-DMA in silver nitrate acetonitrile solution with a concentration of 0.01mol / L, stir at room temperature under light-shielded environment, and the reaction time is 6h. °C for 24 hours in vacuum to obtain the metal-organic framework Ag@Cu-BTC-DMA.

[0043] 2. Detection of metal organic framework

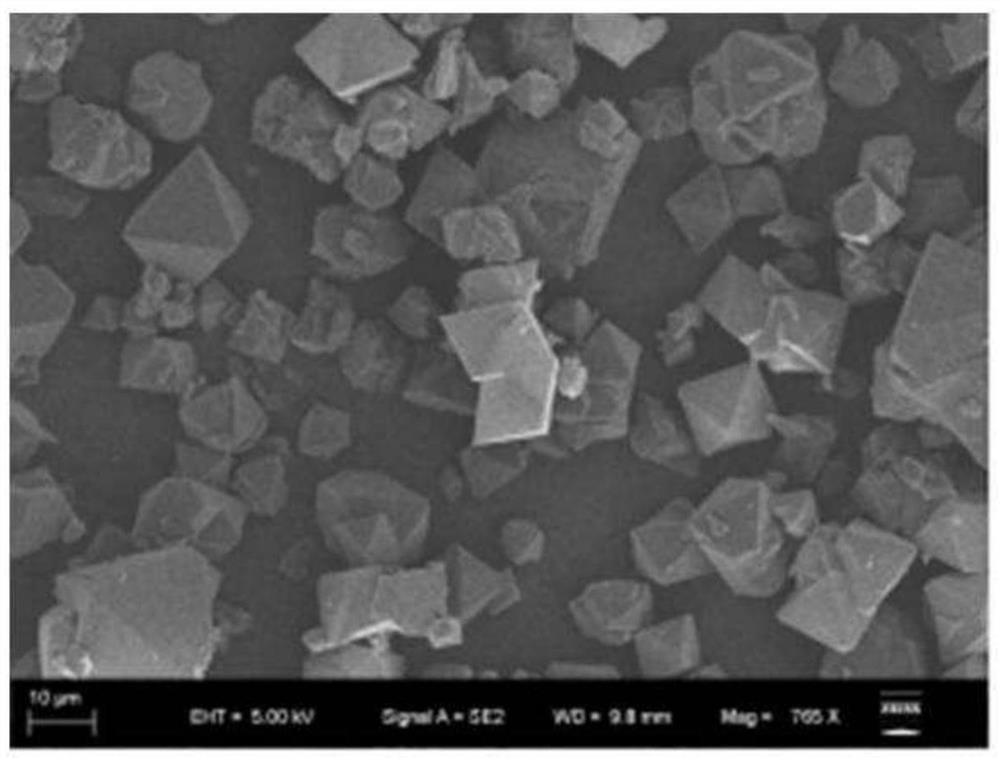

[0044] The mass percentage of Ag ions measured by inductively coupled plasma mass spectrometry ICP is 3.95%; figure 2 ...

Embodiment 2

[0048] 1. Preparation of metal-organic frameworks

[0049] Mix copper chloride dihydrate and trimesic acid in 500mL polytetrafluoroethylene liner, stir at room temperature for 2 hours, add N,N-dimethylacetamide, the molar ratio of the three is 2.25:1.25:0.25, and stir Mix evenly until the solids are completely dissolved, put the liner into the high-pressure reactor, react at 120°C for 72 hours to obtain the reaction mother liquor, cool to room temperature, filter with suction, dry in vacuum, and wash with N,N-dimethylacetamide to obtain Cu-BTC-DMA;

[0050] Under dark conditions, dissolve Cu-BTC-DMA in silver nitrate acetonitrile solution with a concentration of 0.03mol / L, stir at room temperature under dark conditions, and the reaction time is 12h. °C under vacuum to obtain the metal-organic framework Ag@Cu-BTC-DMA.

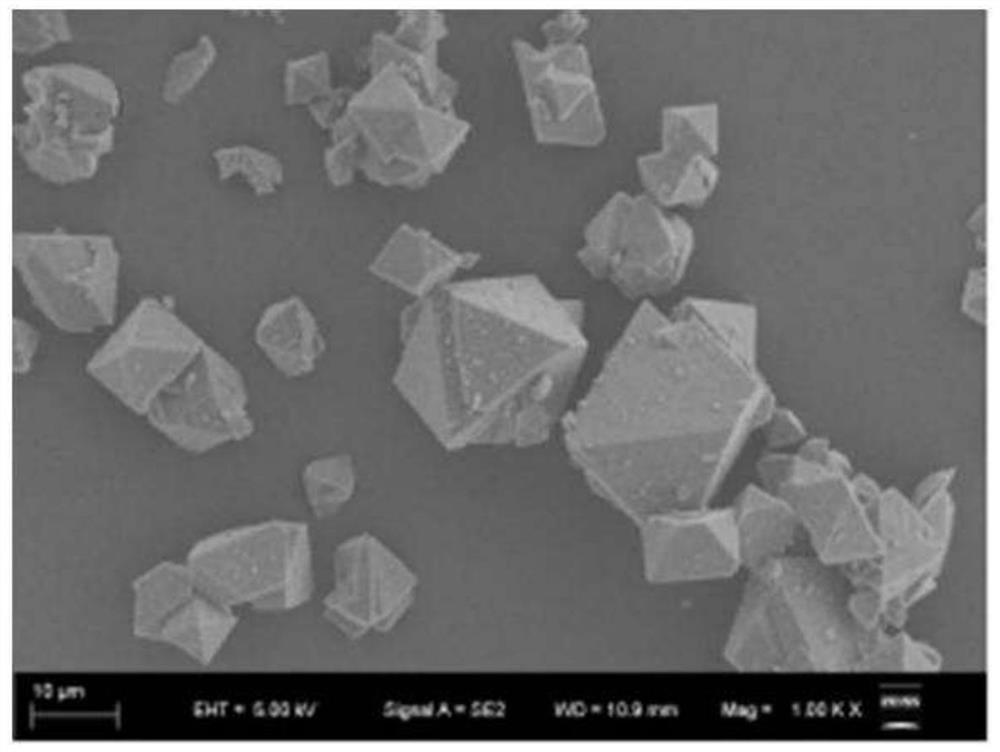

[0051] 2. Detection of metal organic framework

[0052] The mass percentage of Ag ions measured by inductively coupled plasma mass spectrometry ICP is 3.66%;...

Embodiment 3

[0056] 1. Preparation and application of metal-organic frameworks

[0057] Mix copper chloride dihydrate and trimesic acid in 500mL polytetrafluoroethylene liner, stir at room temperature for 4 hours, add N,N-dimethylacetamide, the molar ratio of the three is 2.5:1.5:0.5, and stir Mix evenly until all the solids are dissolved, put the liner into the autoclave, react at 100°C for 48 hours to obtain the reaction mother liquor, cool to room temperature, filter with suction, wash, vacuum dry, and wash with methanol with suction to obtain Cu-BTC-DMA;

[0058] Under light-shielded conditions, dissolve Cu-BTC-DMA in silver nitrate acetonitrile solution with a concentration of 0.02mol / L, stir at room temperature under light-shielded environment, and the reaction time is 8h. ℃ vacuum drying for 24h, the metal organic framework Ag@Cu-BTC-DMA was obtained.

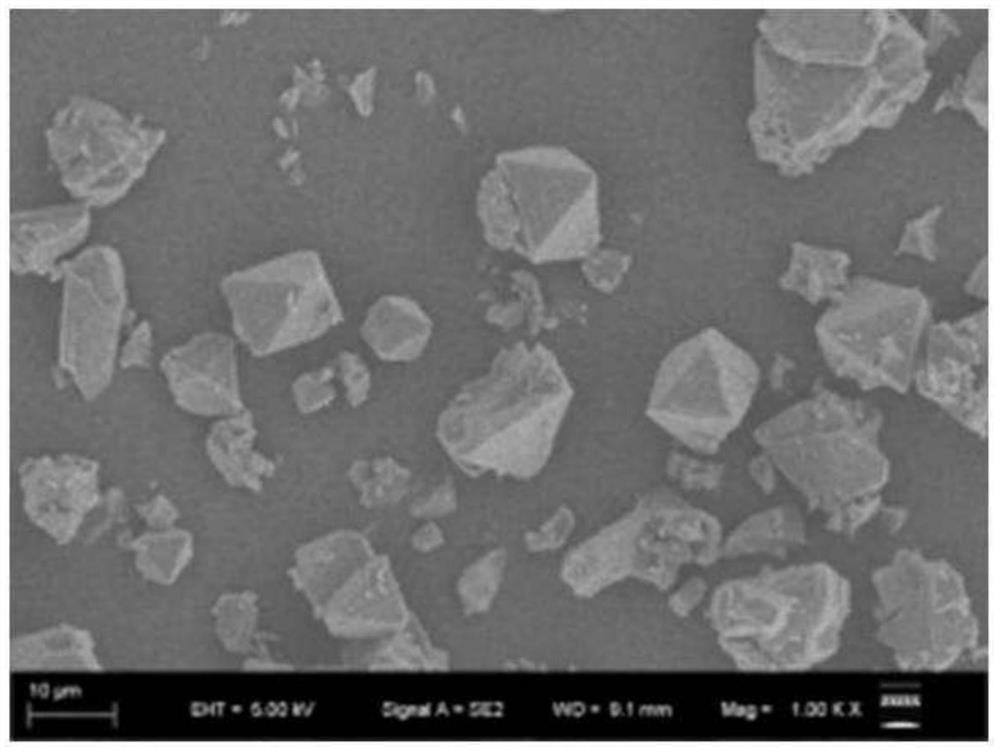

[0059] 2. Detection of metal organic framework

[0060] Inductively coupled plasma mass spectrometry ICP measured the mass percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com