Molecular sieve based catalyst capable of degrading formaldehyde at normal temperature as well as preparation method and application of molecular sieve

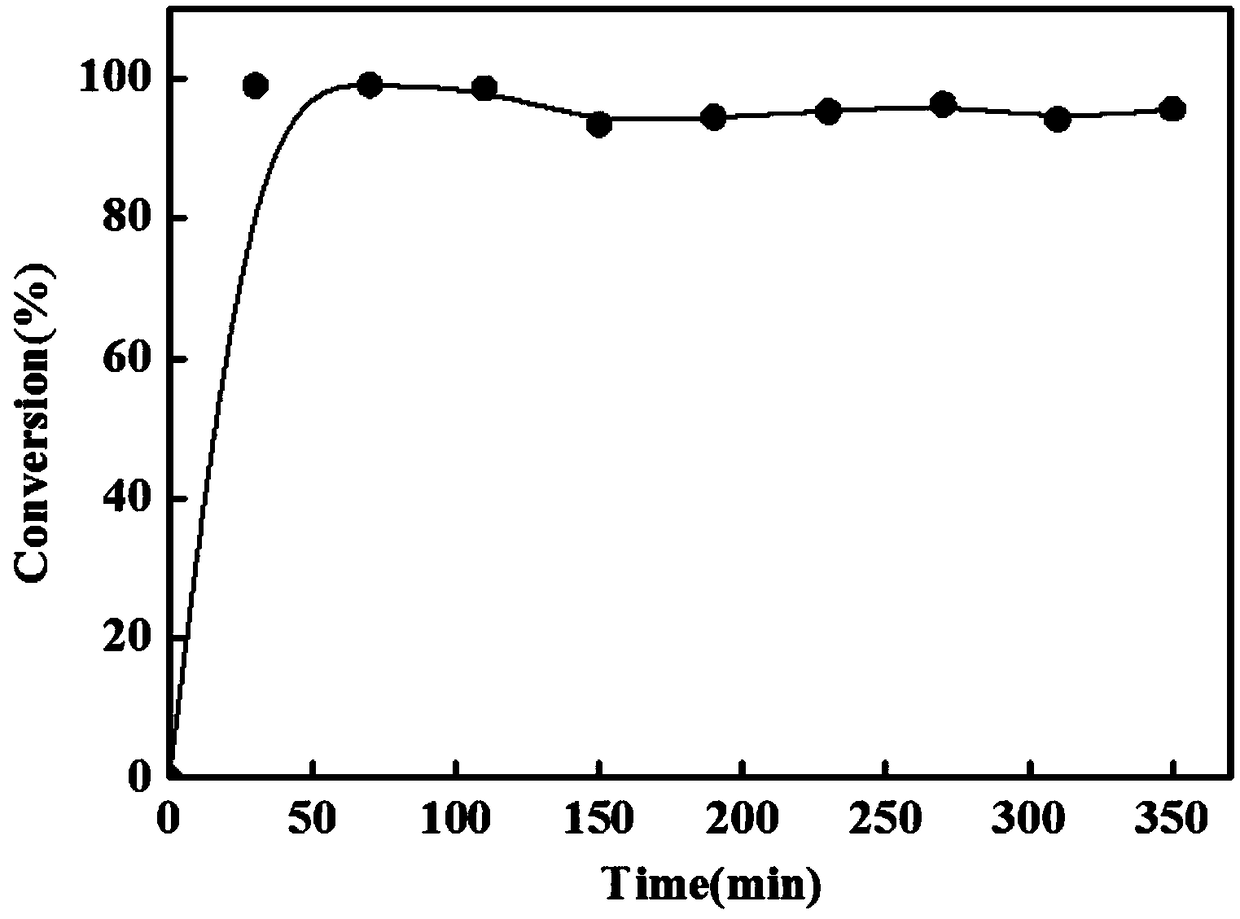

A molecular sieve and catalyst technology, which is applied in the field of molecular sieve catalyst for degrading and removing formaldehyde at room temperature and its preparation field, can solve the problem of inability to reduce the formaldehyde concentration to the national standard, etc., and achieve the effect of simple steps and less loaded precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

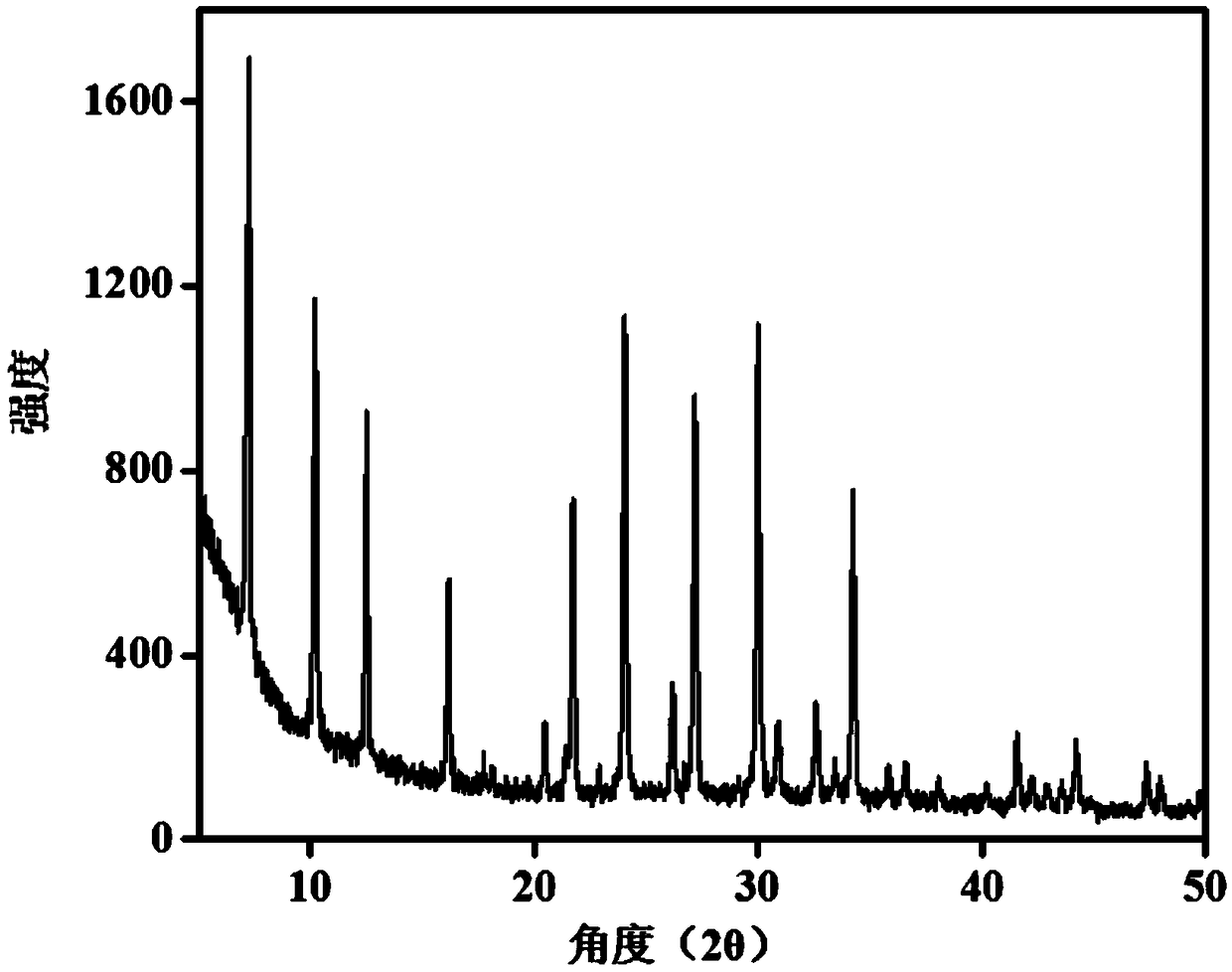

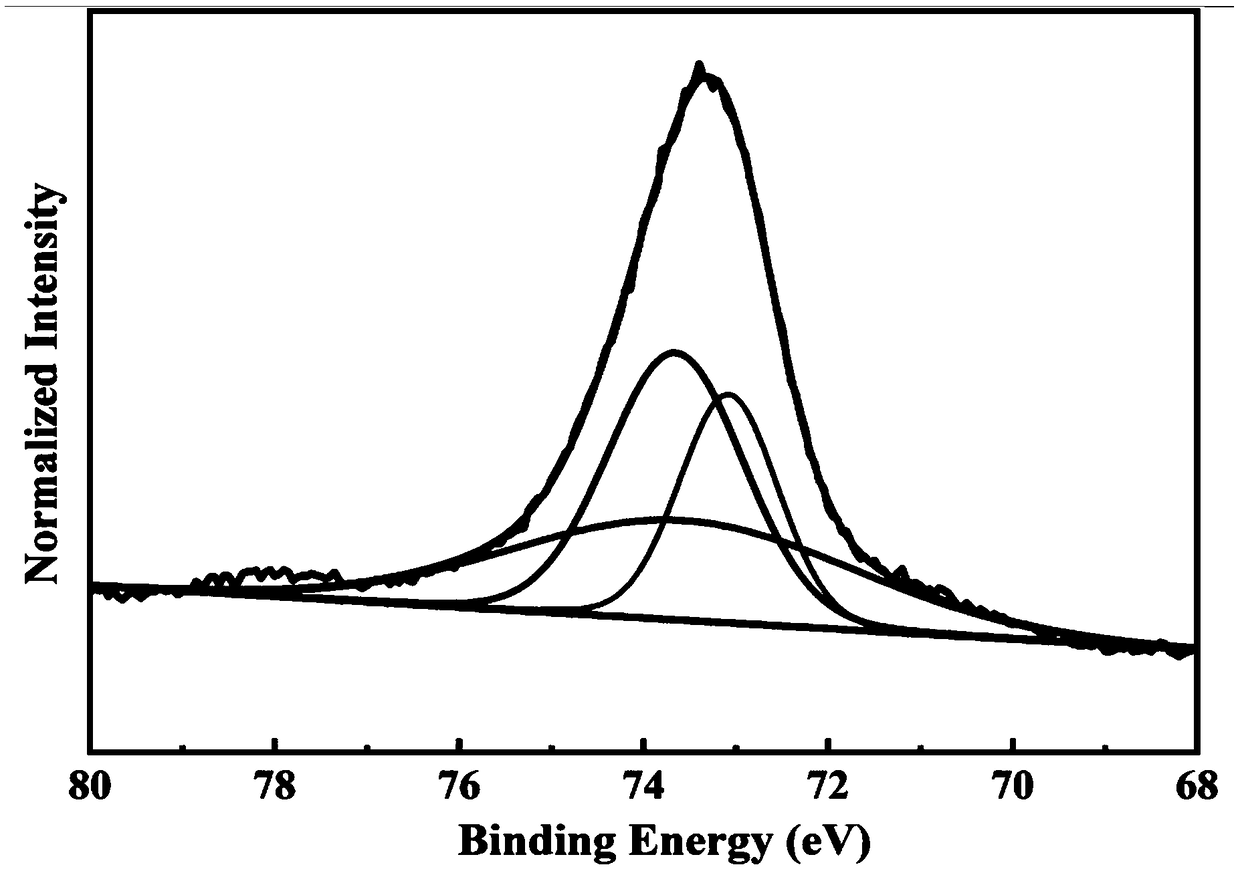

[0034] 2.951g NaAlO 2 (M=81.97) and 2.355 g of NaOH (M=40) were dissolved in 22 mL of deionized water, and magnetically stirred at 300 rpm at room temperature to obtain liquid A. 1.5g of Fumed SiO 2 (M=60.084) was added to the above liquid A, and magnetically stirred at 300 rpm at room temperature to prepare liquid B. The obtained liquid B was sealed in a polytetrafluoroethylene plastic bottle, and stirred at room temperature and 800 rpm for 10 min to obtain liquid C. The prepared liquid C was stirred in an oil bath at 400 rpm and 60° C. for 3 hours. Platinum nitrate solution (0.4g platinum nitrate, 10ml water) was prepared, 10mL was added dropwise to the above-prepared solution, and then the obtained mixture was stirred uniformly at 400rpm and 60°C for 1 hour to form a gel. Then the gel was heated to 100° C. and crystallized at 100° C. and 400 rpm for 16 hours. The crystallized solution was filtered (Buchner funnel), washed with deionized water until neutral. Then dry in...

Embodiment 2

[0036] 2.951g NaAlO 2 (M=81.97) and 2.355 g of NaOH (M=40) were dissolved in 22 mL of deionized water, and magnetically stirred at 300 rpm at room temperature to obtain liquid A. 1.5g of Fumed SiO 2 (M=60.084) was added to the above liquid A, and magnetically stirred at 300 rpm at room temperature to prepare liquid B. The obtained liquid B was sealed in a polytetrafluoroethylene plastic bottle, and stirred at room temperature and 800 rpm for 10 min to obtain liquid C. The prepared liquid C was stirred in an oil bath at 400 rpm and 60° C. for 3 hours. Platinum nitrate solution (0.2g platinum nitrate, 10ml water) was prepared, and 10mL was added dropwise to the above-prepared solution, and then the obtained mixture was stirred evenly at 400rpm and 60°C for 1 hour to form a gel. Then the gel was heated to 100° C. and crystallized at 100° C. and 400 rpm for 16 hours. The crystallized solution was filtered (Buchner funnel), washed with deionized water until neutral. Then dry i...

Embodiment 3

[0038] 2.951g NaAlO 2 (M=81.97) and 2.355 g of NaOH (M=40) were dissolved in 22 mL of deionized water (magnetic stirring) to obtain liquid A. 1.5g of Fumed SiO 2 (M=60.084) was added to the above liquid A (magnetic stirring) to prepare liquid B. The obtained liquid B was sealed in a polytetrafluoroethylene plastic bottle, and stirred at room temperature and 700 rpm for 15 min to obtain liquid C. The prepared liquid C was stirred in an oil bath at 400 rpm and 70° C. for 3 hours. Platinum nitrate solution (0.4g platinum nitrate, 10ml water) was prepared, 10mL was added dropwise to the above-prepared solution, and then the obtained mixture was stirred uniformly at 400rpm and 60°C for 1 hour to form a gel. Then the gel was heated to 90° C. and crystallized at 90° C. and 400 rpm for 18 hours. The crystallized solution was filtered (Buchner funnel), washed with deionized water until neutral. Then it was dried in an oven at 100° C. for 10 hours. The prepared molecular sieve was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com