A quaternary ammonium salt suitable for flotation

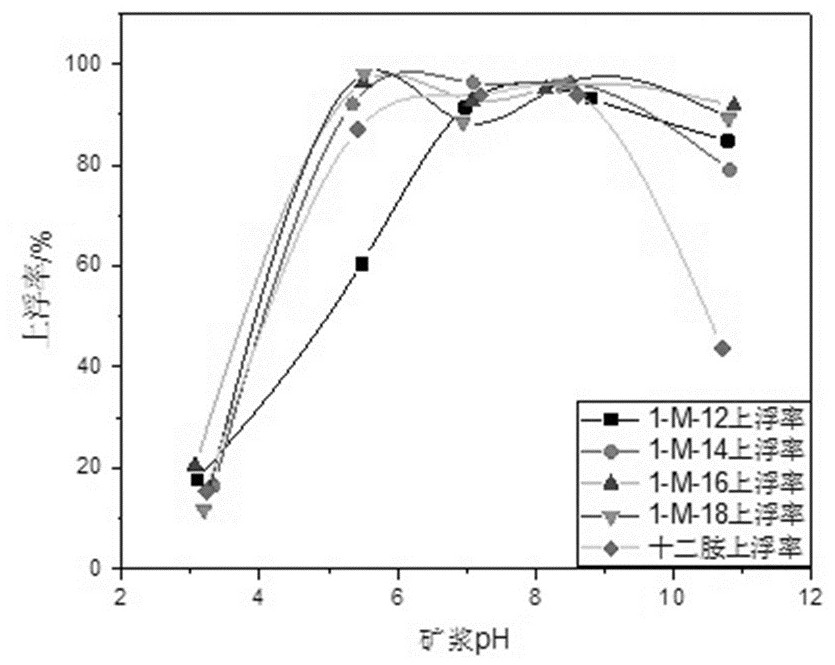

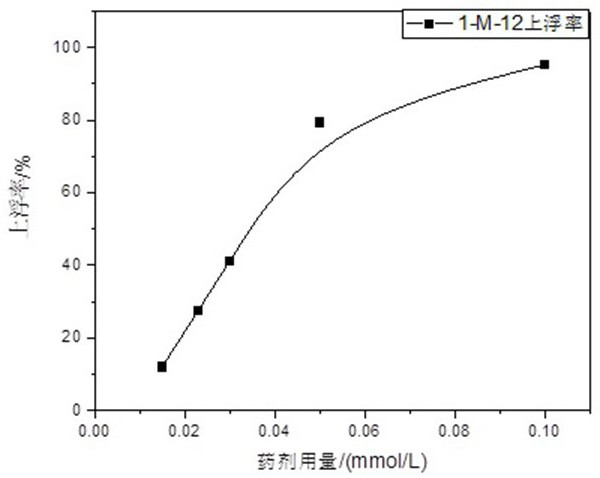

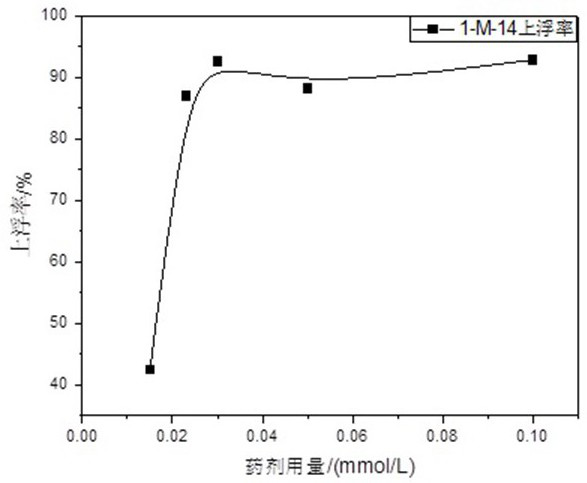

A technology of quaternary ammonium salts and intermediates, applied in the field of chemical synthesis, which can solve the problems of large dosage, high cost, and application limitations of quaternary ammonium salts, and achieve strong collection performance and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 4.7786g of trimethylamine hydrochloride in 18.18g of absolute ethanol, drain it with a glass rod, and pour it into a 25mL three-neck flask; adjust the temperature of the water bath to 30°C; weigh 4.626g of epichlorohydrin, and pour it into a constant pressure In the dropping funnel, slowly add dropwise at a rate of 0.3ml / min; react for 0.5 hours, cool for 2.5 hours, the reactant in the three-necked flask turns into white crystals, and Intermediate A is obtained.

[0030] After the product in the first step is crystallized, add 13.15g of ethanol to the three-necked flask; adjust the temperature of the water bath to 75°C; The solution was poured into a constant pressure dropping funnel, and slowly dropped into a three-necked beaker at a rate of 0.5ml / min; reacted for 4.5h to obtain intermediate B.

[0031] Distill at 90°C under normal pressure to remove ethanol to obtain a quaternary ammonium salt suitable for flotation (2-hydroxy---N1, N2, N3, N3-pentamethyl-N3-...

Embodiment 2

[0033] Dissolve 4.7786g of trimethylamine hydrochloride in 18.18g of absolute ethanol, drain it with a glass rod, and pour it into a 25mL three-neck flask; adjust the temperature of the water bath to 35°C; weigh 4.626g of epichlorohydrin, and pour it into a constant pressure In the dropping funnel, slowly add dropwise, 0.4ml / min; react for 1 hour, cool for 3 hours, the reactant in the three-necked flask turns into white crystals, and Intermediate A is obtained.

[0034] After the product in the first step is crystallized, add 13.15g of ethanol to the three-necked flask; adjust the temperature of the water bath to 80°C; The solution was poured into a constant pressure dropping funnel, and slowly dropped into a three-necked beaker at a rate of 0.7ml / min; reacted for 5 hours to obtain intermediate B.

[0035] Distill at 95°C under normal pressure to remove ethanol to obtain a quaternary ammonium salt suitable for flotation (2-hydroxy---N1, N2, N3, N3-pentamethyl-N3--tetradecylpro...

Embodiment 3

[0037] Dissolve 4.7786g of trimethylamine hydrochloride in 18.18g of absolute ethanol, drain it with a glass rod, and pour it into a 25mL three-neck flask; adjust the temperature of the water bath to 40°C; weigh 4.626g of epichlorohydrin, and pour it into a constant pressure In the dropping funnel, slowly add dropwise, 0.5ml / min; react for 1.5 hours, cool for 3.5 hours, the reactant in the three-necked flask turns into white crystals, and intermediate A is obtained.

[0038] After the product in the first step is crystallized, add 13.15g of ethanol to the three-necked flask; adjust the temperature of the water bath to 85°C; mix the mixed 13.476g of N,N-dimethyldodecylamine and 6.5854g of absolute The solution was poured into a constant pressure dropping funnel, and slowly dropped into a three-necked beaker at a rate of 0.9ml / min; reacted for 5.5h to obtain intermediate B.

[0039] Distill at 100°C under normal pressure to remove ethanol to obtain a quaternary ammonium salt sui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com