A casting device for cylinder liner molding

A cylinder liner and frame technology, applied in the field of cylinder liner molding casting devices, can solve the problems of low production efficiency and long waiting time, achieve the effect of continuous cooling, reduce waiting time, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

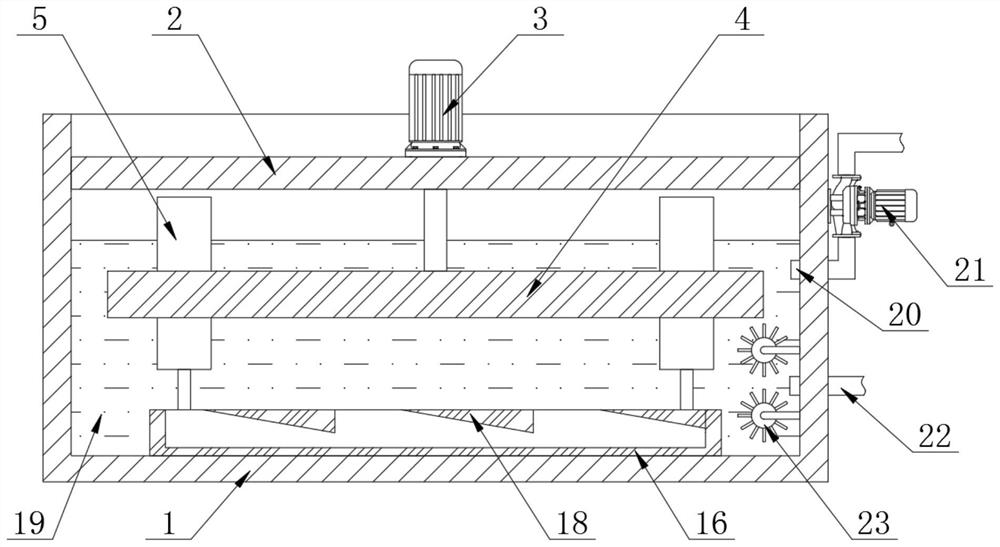

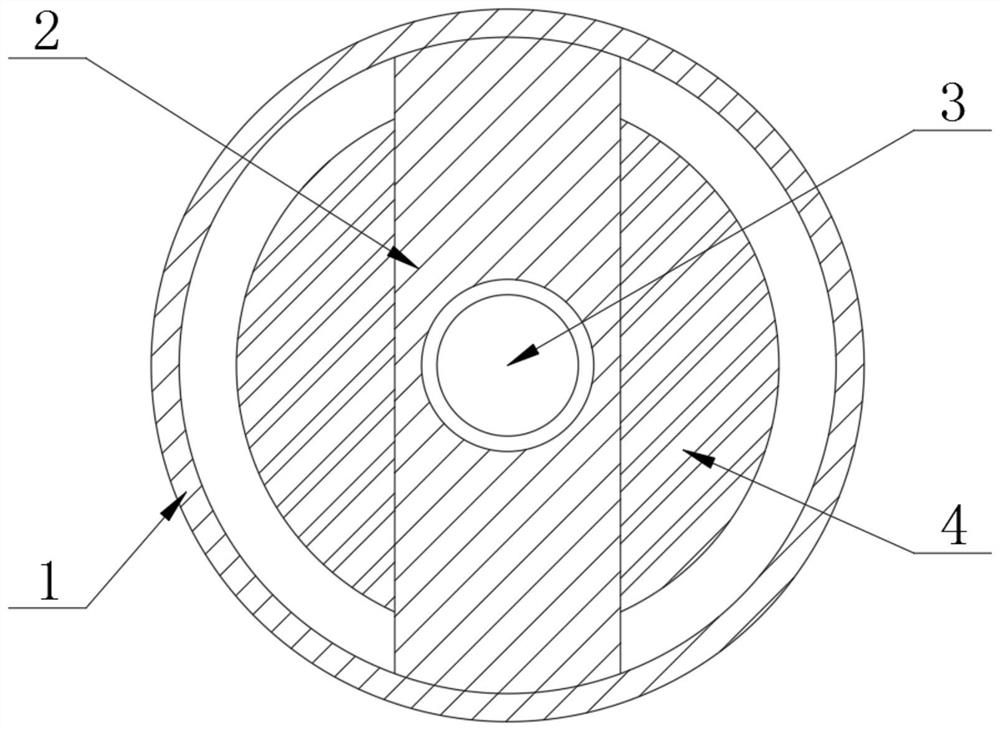

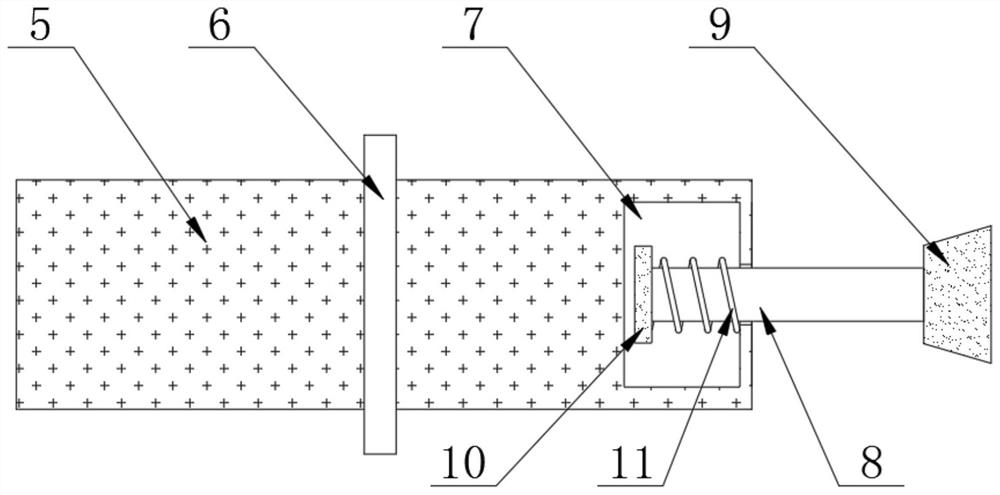

[0024] according to Figure 1-5 The shown casting device for cylinder liner molding includes a frame 1, the top of the frame 1 is provided with a connecting plate 2, the top of the connecting plate 2 is provided with a transmission motor 3, and the output shaft of the transmission motor 3 is One end is provided with a drive plate 4, the interior of the drive plate 4 is provided with a pouring mold body 5, the outer wall of the pouring mold body 5 is provided with a positioning block 6, and one end of the pouring mold body 5 is provided with a receiving cavity 7. A connecting rod 8 is provided inside the receiving cavity 7, a slider 9 is provided at one end of the connecting rod 8, and a knocking block 10 is provided at the other end of the connecting rod 8, and a connection between the knocking block 10 and the inner wall of the receiving cavity 7 is provided. A telescopic spring 11 is arranged between them, and a through groove 12 is provided at the connection between the dri...

Embodiment 2

[0031] according to figure 2 As shown in a casting device for cylinder liner molding, the inner cavity of the frame 1 is provided with cooling water 19, the height of the cooling water 19 is lower than the top position of the pouring mold body 5, and the cooling water 19 is opposite to the pouring mold body 5 When the castings inside are cooling down, the temperature of the cooling water 19 is gradually warming up;

[0032] One side of the frame 1 is provided with a water outlet pipe 20, the water delivery pipe is provided with a water pump 21, the water pump 21 is arranged on the outer wall of the frame 1, the bottom of the water outlet pipe 20 is provided with a water inlet pipe 22, and the cooling water 19 is provided according to When the temperature is higher, the density is lower. The heated cooling water 19 is drawn from the rack 1 by the outlet pipe 20 at the top under the action of the water pump 21, and is discharged to the inside of the external cooling pool for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com