Single-face clamping hole forming method of double-side stepped hole part

A technology of stepped holes and parts, which is applied in the field of single-sided clamping of double-sided stepped hole parts, can solve the problems that the coaxiality of three holes cannot be guaranteed, the processing efficiency of parts is reduced, and the number of tool preparations is increased, so as to reduce the number of installations. The effect of changing the number of clips and datums, improving machining accuracy, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

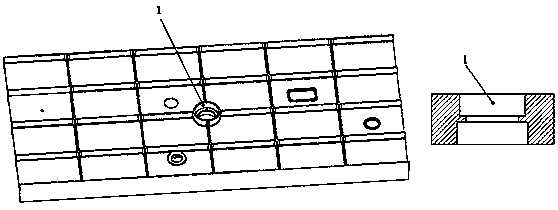

[0033] like figure 1 As shown, a single-side clamping hole-making method for double-sided stepped hole parts mainly includes the following steps:

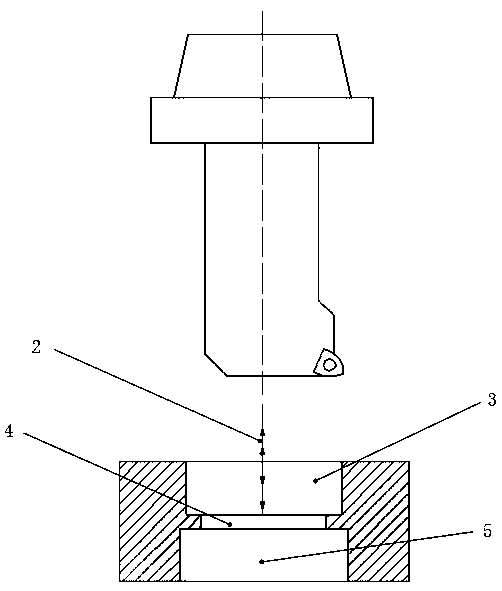

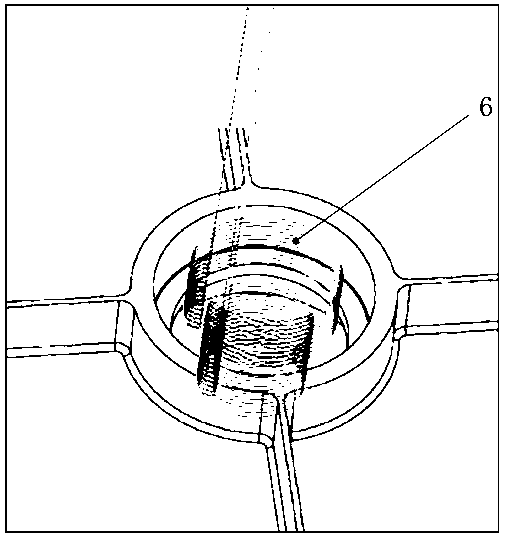

[0034] Step S3: finely bore the upper counterbore 3 and the stepped hole 4 respectively, and after installing the boring tool 14, determine the direction of the tool tip of the boring tool head 15 when the machine tool is at SPOS=0, and use the pointing of the tool tip as the positive direction of the X-axis; then Extend the boring tool 14 into the hole along the Y axis to bore the hole. After boring the hole, the machine tool stops and ensures that the tip of the boring tool 14 is still pointing to the positive direction of the X axis; then the boring tool 14 moves back along the negative direction of the X axis. 1 =0.1mm, then withdraw upward along the Y axis;

[0035] The double-sided stepped hole 1 has three parts: the upper sink hole 3, the stepped hole 4 and the sink hole 5, and the rough milling of these three holes is carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com