Shot blasting machine for removing metal edges and corners

A technology of shot blasting machine and edges and corners, which is applied in the direction of metal processing equipment, surface polishing machine tools, machine tools suitable for grinding workpiece edges, etc., which can solve problems such as high price, product scrapping, and environmental damage on the production site, and improve the quality of finished products. High efficiency, strong practicability, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

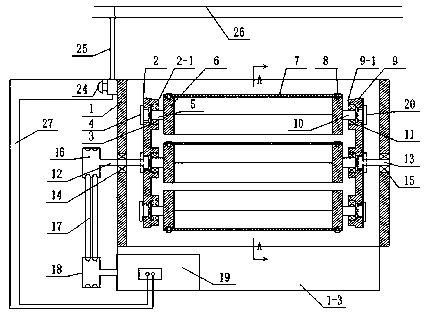

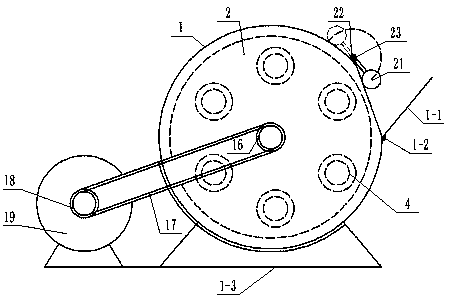

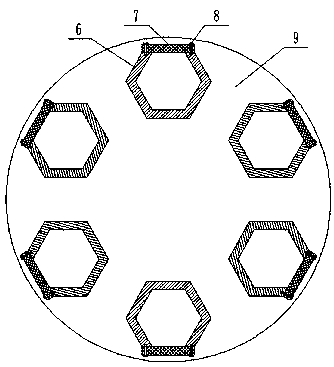

[0036] combine Figure 1 to Figure 19 A shot blasting machine for removing metal edges and corners according to the present invention will be further described.

[0037] In a preferred embodiment of a shot blasting machine for removing metal edges and corners according to the present invention, its structure consists of: bracket 1, safety door 1-1, hinge 1-2, base 1-3, left turntable 2, left bearing Seat 2-1, first convex through hole 2-2, left bearing 3, left plug 4, left short shaft 5, hexagonal hopper 6, feed port 6-1, bolt hole 6-2, hopper cover 7. Bolt 8, right turntable 9, right bearing seat 9-1, second convex through hole 9-2, right short shaft 10, right bearing 11, left connecting shaft 12, right connecting shaft 13, bracket left bearing 14 , bracket right bearing 15, driven pulley 16, transmission belt 17, driving pulley 18, motor 19, right block 20, pressure hammer 21, flip fixing block 22, rotating shaft 23, switch 24, lower live wire 25, external power supply Lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com