Quantitative feeding device for plastic tableware production

A technology of quantitative feeding and plastic tableware, which is applied in the field of tableware production, can solve the problems that various raw materials cannot be mixed automatically and uniformly, it is not suitable for automatic batch production of plastic tableware, and affects the production efficiency of plastic tableware, etc., and achieves a small footprint , ingenious design, and the effect of improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

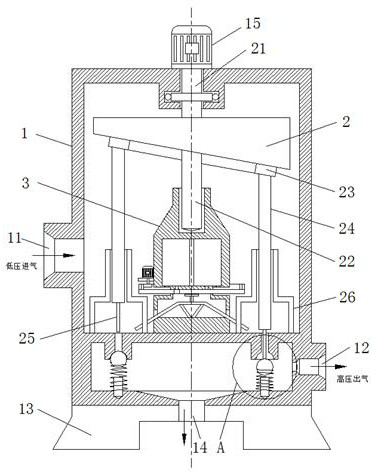

[0030] refer to Figure 1-6 , a quantitative feeding device for plastic tableware production, comprising a device body 1, a drive mechanism, a feeding mechanism, and an activity control mechanism cooperating with the drive mechanism are arranged inside the device body 1;

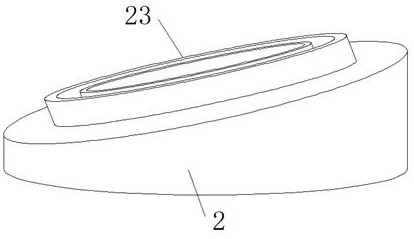

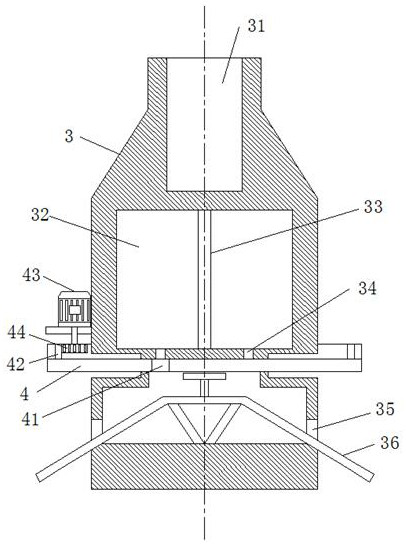

[0031] The drive mechanism includes a rotating base 2 that is rotatably installed on the inner wall of the top of the device body 1. The bottom of the rotating base 2 is provided with a connecting guide rail 23, and the bottom of the connecting guide rail 23 is slidingly installed with two opposite movable vertical rods 24. The movable vertical rod 24 The bottom of the bottom is connected with a push rod 25, and the activity control mechanism includes a blocking ball 16 located below the push rod 25 and in contact with the push rod 25. The bottom of the blocking ball 16 is provided with a spring 17, and the spring 17 is provided with a positioning rod 18;

[0032] The feeding mechanism includes a feeding sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com