O-phenyl type photo-curable unsaturated polyester resin and preparation method thereof

A polyester resin and light-curing technology, which is applied in the field of ortho-phthalic light-curing unsaturated polyester resin and its preparation, can solve the problem that the shape of decorations does not meet the requirements, the surface of components has cracks, and the degree of curing of deep structures is not enough. Complete and other problems, to achieve the effect of low curing shrinkage, not easy to crack, and durable weather resistance

Inactive Publication Date: 2019-01-11

惠州市固德尔合成材料有限公司

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The unsaturated polyester used in the production of decorations needs to have the ability of rapid curing and molding in the processing technology, because the decorations used in decoration engineering have more complex three-dimensional shapes, if the unsaturated resin cannot be quickly and uniformly formed during the molding process Curing, shrinkage and deformation will occur during the molding process and the curing degree of the deep structure will not be complete, resulting in the shape of the molded decoration not meeting the required shape or cracks on the surface of the component. Good unsaturated polyester is especially important

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

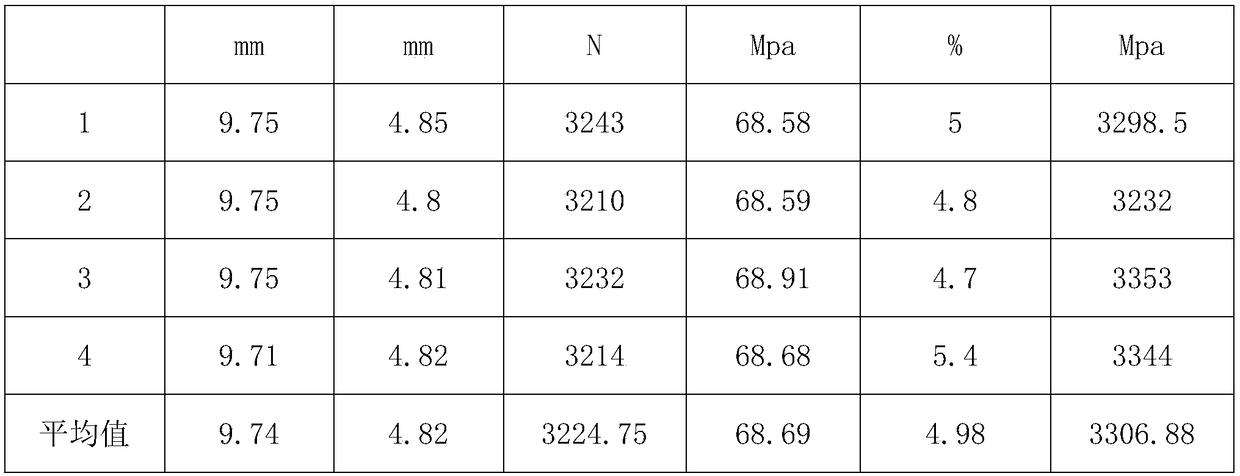

[0015] In order to further understand the content of the invention, features and effects of the present invention, the following examples are listed below for illustration.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses o-phenyl type photo-curable unsaturated polyester resin comprising the following components in parts by weight: 10-15 parts of maleic anhydride, 18-25 parts of tetrahydrophthalic anhydride, 10-15 parts of ethylene glycol, 10-15 parts of propylene glycol, 25-30 parts of styrene, 2-5 parts of a composite photoinitiator, 1-3 parts of an ultraviolet absorbent, 0.3-0.5 part of aleveling agent and 0.08-0.1 part of methylhydroquinone. The prepared o-phenyl type photo-curable unsaturated polyester resin has the characteristics of medium viscosity, medium reaction activity, mild heat release and high solid content, and can be cured rapidly under the action of the accelerator and the photo-initiator. The material processed and molded by the o-phenyl type photo-curable unsaturated polyester resin has good light transmittance, jade texture, durable weathering resistance, and low curing shrinkage. When forming a molding sheet product with complex and deep structure, crackscan be guaranteed not to be easily produced in the deep structure.

Description

technical field [0001] The invention belongs to the technical field of polymer materials, and in particular relates to an ortho-phthalic light-cured unsaturated polyester resin and a preparation method thereof. Background technique [0002] Unsaturated polyester is a strong and tough polymer material after cross-linking and curing. It is often used as a substrate for coatings, glass fiber reinforced plastics and decorations, and has a good application prospect. The unsaturated polyester used in the production of decorations needs to have the ability of rapid curing and molding in the processing technology, because the decorations used in decoration engineering have more complex three-dimensional shapes, if the unsaturated resin cannot be quickly and uniformly formed during the molding process Curing, shrinkage and deformation will occur during the molding process and the curing degree of the deep structure will not be complete, resulting in the shape of the molded decoration...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G63/52C08F283/01C08F212/08C08F2/48

CPCC08F283/01C08G63/52C08F212/08C08F2/48

Inventor 张涛程炽能王陈禹

Owner 惠州市固德尔合成材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com