Sealant for water content measuring device

A measuring device and sealant technology, applied in the direction of adhesives, epoxy glue, adhesive types, etc., can solve the problems that electronic components cannot be bent and installed at will, the sealing surface is difficult to repair, and the elongation at break is low. Achieve the effect of excellent flexibility, high light transmittance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

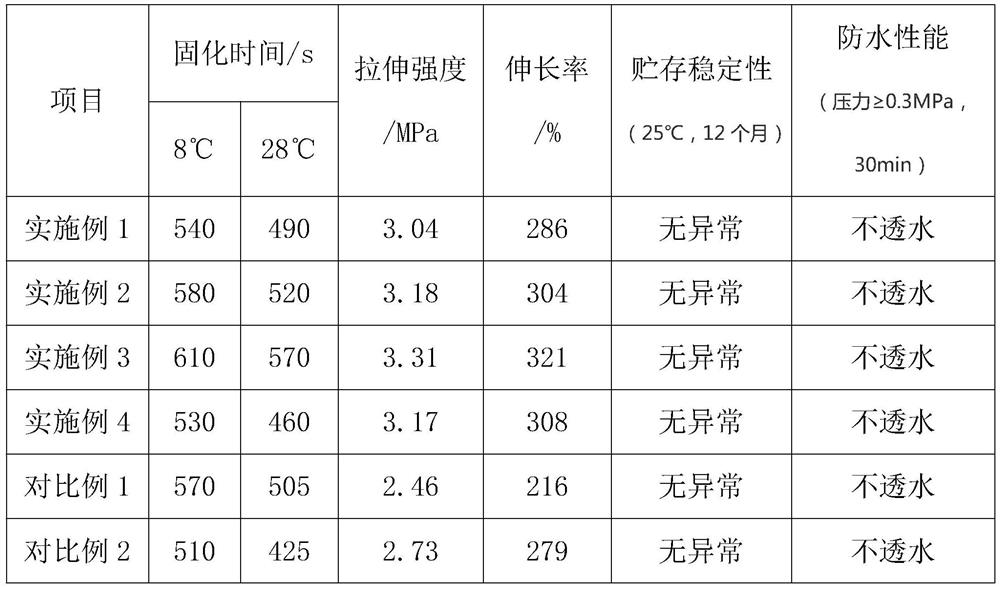

Examples

Embodiment 1

[0031] This embodiment discloses a sealant for a water content measuring device, which is composed of two components, A component and B component, wherein the A component includes the following components in parts by weight: 40 parts of modified epoxy resin, 40 parts of polymer 10 parts of tetrafluoroethylene micropowder, 2 parts of diluent, 1 part of dispersant and 0.05 part of defoamer; the B component includes the following parts by weight: 5 parts of epoxy curing agent, 1 part of silane coupling agent, dehydration 1 part of UV absorber and 0.5 part of UV absorber.

[0032] In the present embodiment, the preparation method of the modified epoxy resin is as follows: react the epoxy resin and r-mercaptopropylmethyldimethoxysilane at normal temperature for 3-8 hours to obtain the first reaction product; Under protection, mix toluene diisocyanate and polytetramethylene ether glycol into the solvent dimethylformamide, raise the temperature to 70-80°C, and react for 2-3 hours to ...

Embodiment 2

[0050]The raw materials, preparation method and use method of this embodiment are basically the same as those of Example 1, except that: component A includes the following components in parts by weight: 60 parts of modified epoxy resin, 25 parts of polytetrafluoroethylene micropowder, 5 parts of thinner, 5.5 parts of dispersant and 0.27 parts of defoamer; the B component includes the following parts by weight: 10 parts of epoxy curing agent, 4 parts of silane coupling agent, 3 parts of dehydrating agent and ultraviolet absorber 1.25 servings.

Embodiment 3

[0052] The raw materials, preparation method and use method of this embodiment are basically the same as those of Example 1, except that: component A includes the following components in parts by weight: 80 parts of modified epoxy resin, 40 parts of polytetrafluoroethylene micropowder, 8 parts of diluent, 10 parts of dispersant and 0.5 part of defoamer; The B component includes the following parts by weight: 15 parts of epoxy curing agent, 7 parts of silane coupling agent, 5 parts of dehydrating agent and ultraviolet absorber 2 servings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com