Full automatic underwater sludge treatment machine

A fully automatic, silt technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of fixed design, influence on rivers and waterways, poor treatment effect, etc., achieve reduction of sediment content, wide application range, The effect of high market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

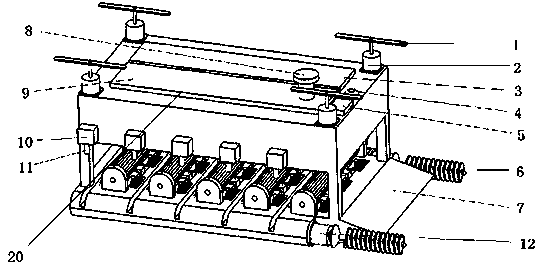

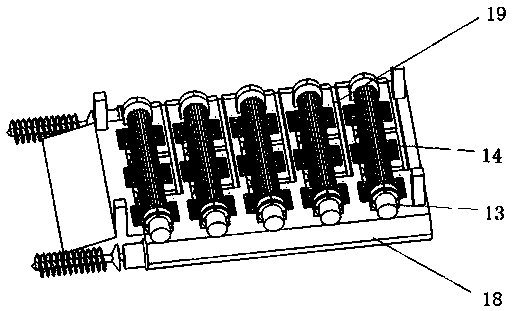

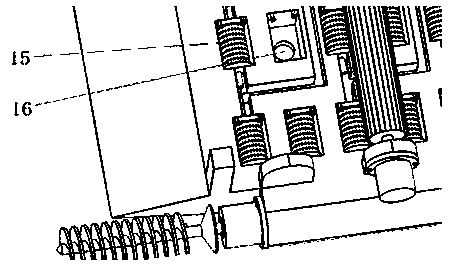

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0018] The invention provides a fully automatic processing machine for underwater sludge, which can move circularly at the bottom of riverbeds and waterways, stir the sludge to a cylindrical oxygen slow-release generating device through a stirring mechanism, and then use the cylindrical oxygen slow-release generating device to raise the sludge The oxygen content in the sludge can promote the metabolic capacity of microorganisms, thereby reducing the sediment content in the sludge, thereby reducing the impact on the water quality of the riverbed and waterways.

[0019] As an embodiment of the present application, the present application provides a fully automatic processing machine for underwater sludge, including a propeller 1, a propeller motor 2, a battery box 3, a control panel 5, a screw propeller 6, a water tank cover 8, a water tank 9, an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com