Seismic resistance, sound insulation and crack resistance integrated structure for internal walls and construction method thereof

A construction method and technology for interior walls, applied to building structures, walls, and earthquake resistance, can solve problems such as poor anti-seismic and crack resistance, inconvenience of scraping paint on interior walls, and affecting construction progress, etc., to achieve improved crack resistance, sound insulation and anti-corrosion Good cracking effect and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

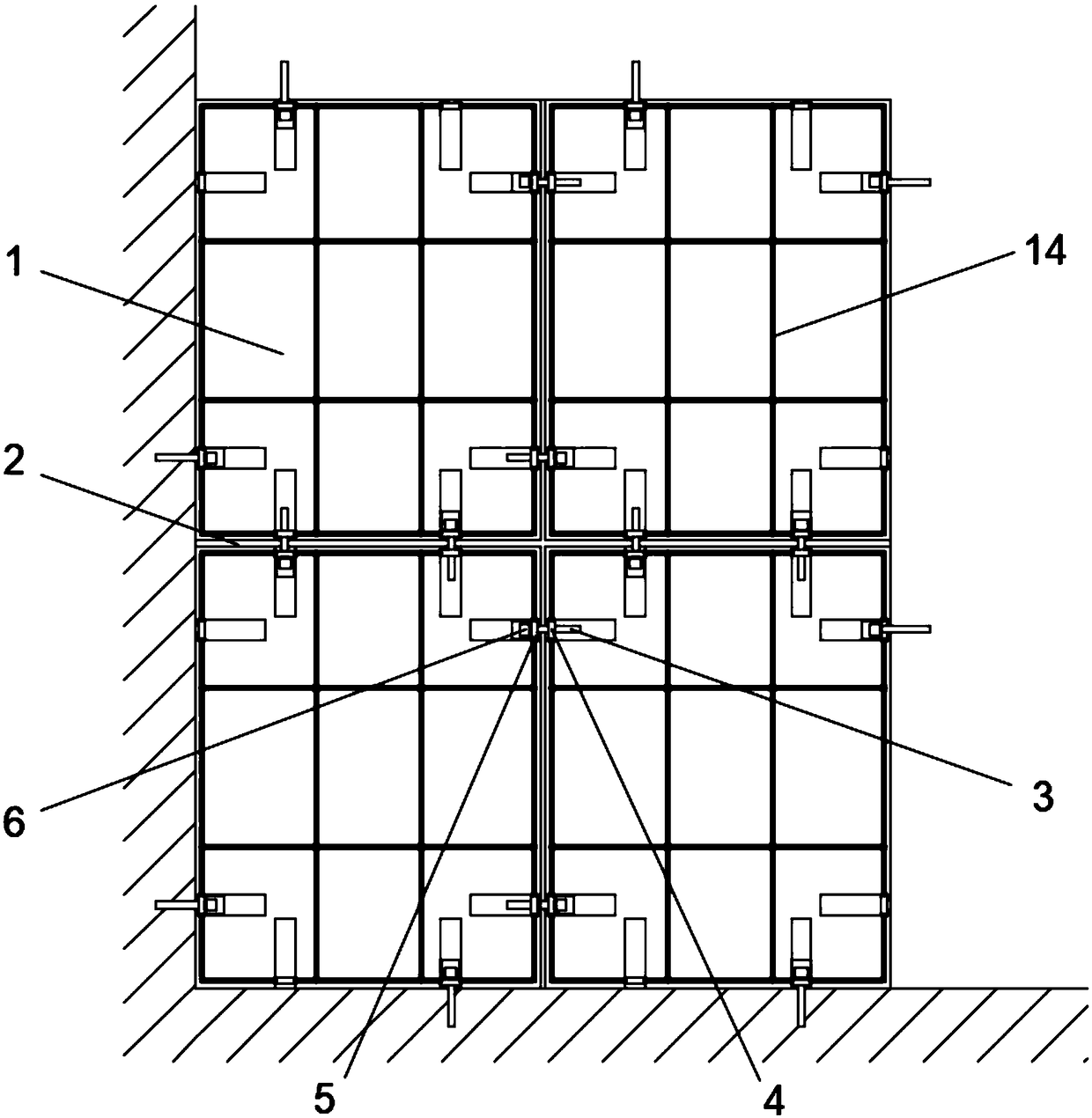

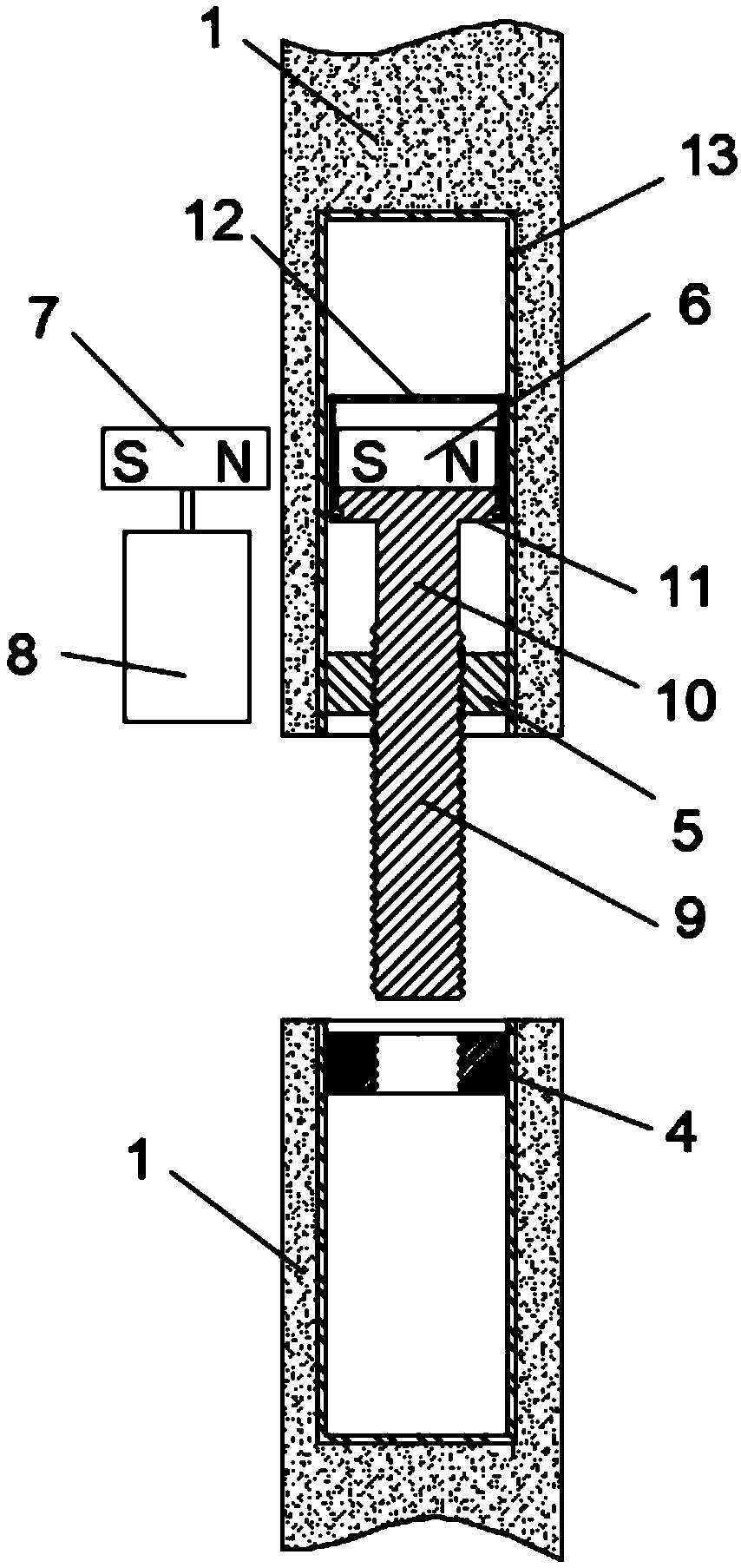

[0025] see Figures 1 to 2 , the integrated structure of anti-seismic, sound insulation and crack resistance of the inner wall, including several square partition wall panels 1, steel bars 14 are arranged inside the partition wall panels 1, and the surroundings of the partition wall panels 1 are connected by connecting mechanisms, and the partition walls The connection between the boards 1 is coated with adhesive 2, and the connection mechanism includes a screw rod 3, a first nut 4 and a second nut 5, the first nut 4 is arranged on the side of the partition wall board 1, and the second nut Two nuts 5 are arranged on the adjacent side of another adjacent said partition board 1, and said first nut 4 and second nut 5 are connected with said reinforcing bar 14, and said first nut 4 and second nut 5 Alignment, the second nut 5 is provided with the screw 3, the screw 3 is provided with a first magnet 6, the first magnet 6 and the second magnet 7 located outside the partition wall 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com