Preparation method for artificial core with preset mesoscopic damage

An artificial core and mesoscopic technology, which is applied in the field of preparation of artificial core with preset mesoscopic damage, can solve the problems of not being able to truly understand the properties of the stratum, avoid the dispersion of experimental data and the difficulty of data comparison and analysis, facilitate operation, The effect of stabilizing physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

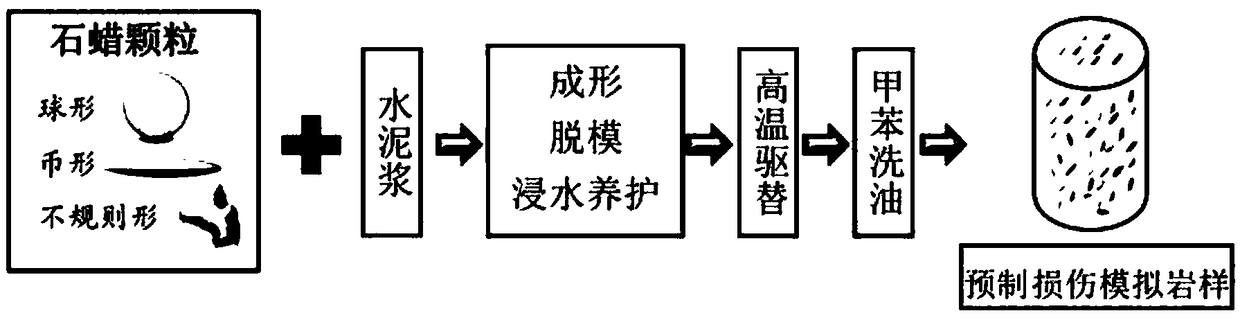

[0029] Such as figure 1 and figure 2 As shown, this embodiment provides a method for preparing artificial rock core with preset mesoscopic damage. The preparation method mainly includes the following steps:

[0030] (1) Mix cement and quartz sand in a mass ratio of 1:3, stir evenly to obtain mixture A; wherein the cement is composite Portland cement, and the quartz sand is selected from 20 mesh;

[0031] (2) Prepare spherical Fischer-Tropsch wax, whose melting point is 96°C, add Fischer-Tropsch wax with a volume ratio of 5% to mixture A, add water according to the ratio of cement to water mass ratio 1:0.65 in mixture A and stir evenly , the mixture B is prepared, and the final water accounts for 20-23% by mass of the mixture B;

[0032] (3) Pour the mixture B into a square mold with lubricating oil on the inner wall, wherein the lubricating oil is selected from GB11121-95 type lubricating oil, and after being stable for 12 hours, the rock block is demoulded to obtain the ro...

Embodiment 2

[0038] This embodiment provides a method for preparing artificial rock core with preset mesoscopic damage. The method steps are as described in Embodiment 1, the difference is that the quartz sand in step (1) is selected from 50 mesh, and the cement and quartz sand are selected according to the mass. Mix at a ratio of 1:1.

Embodiment 3

[0040] This example provides a method for preparing artificial rock core with preset mesoscopic damage, the method steps are as described in Example 1, the difference is that cement and quartz sand are mixed at a mass ratio of 1:1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com