Clamping device suitable for testing shear property of fiber reinforcement bodies and prepregs thereof

A fiber reinforcement and prepreg technology, which is applied in the direction of using a stable shear force to test the strength, strength characteristics, measuring devices, etc. Structural stability, testing the effect of shear deformation and large-angle shear deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

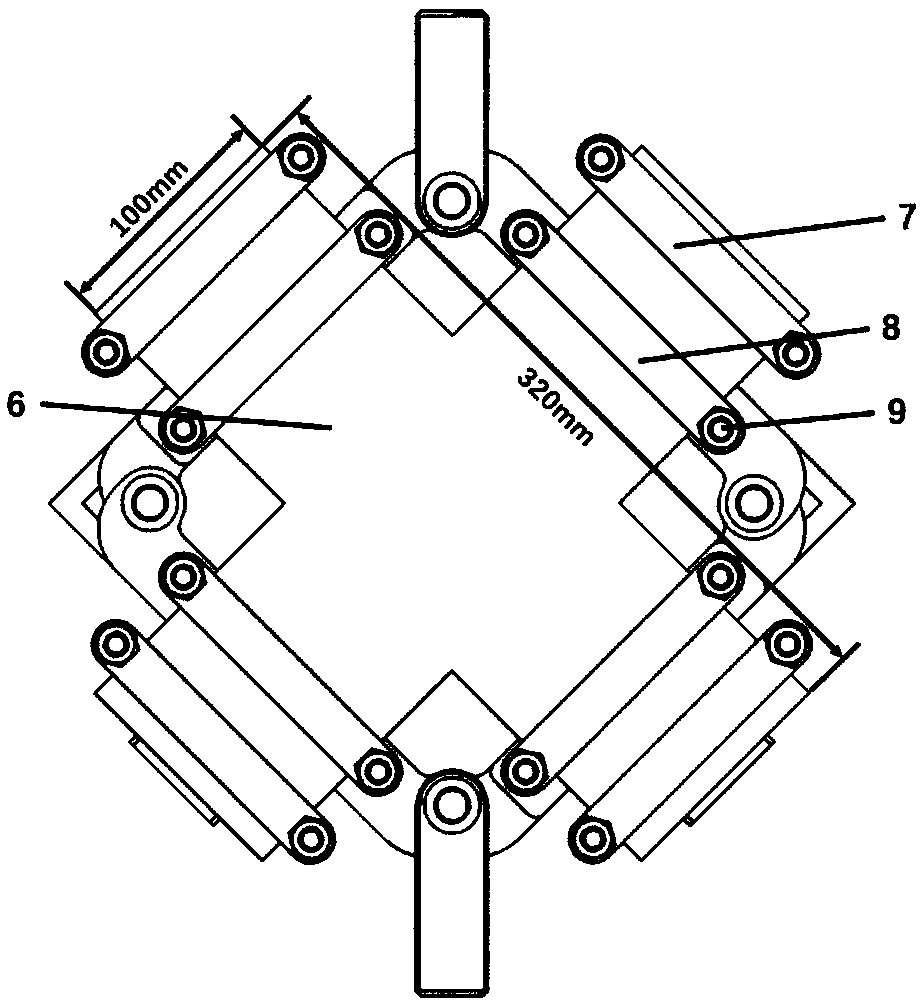

[0045] Step 1: Prepare the test sample, cut the T300 plain weave carbon fiber cloth to be tested to the specified shape, the long side is 320mm, the short side is 100mm in a cross-shaped pattern, the warp and weft yarn direction of the fiber cloth is consistent with the cross direction,

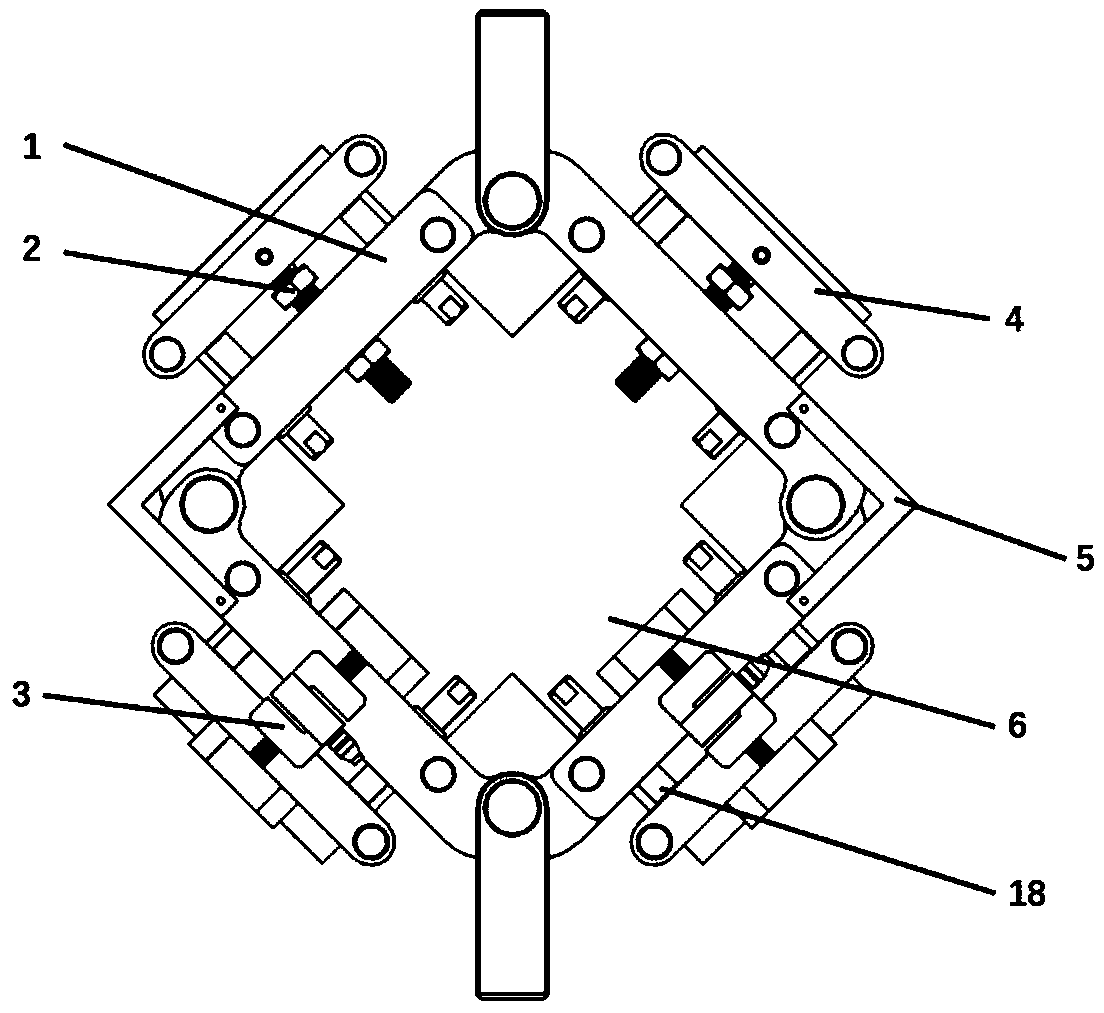

[0046] Step 2: Install the main frame on the tensile testing machine and install the tension-compression sensor 3 on the main frame and power on.

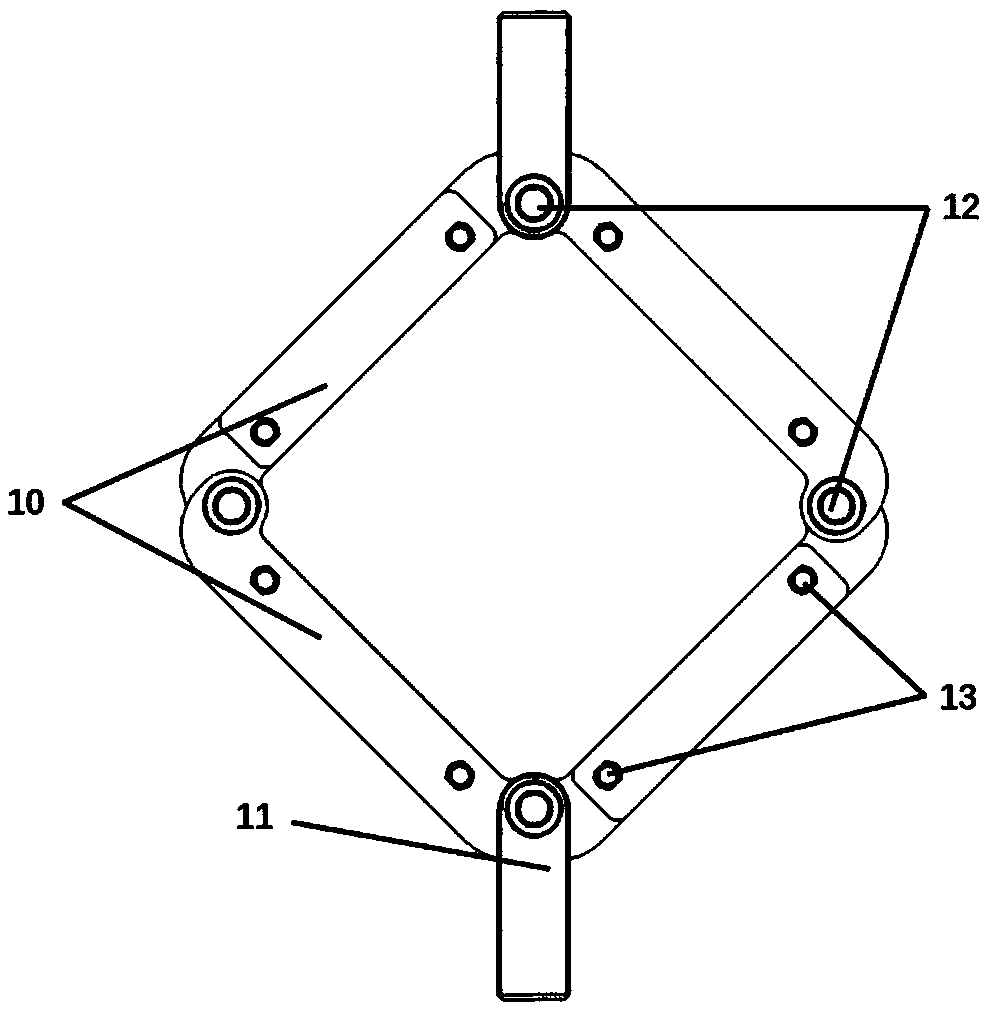

[0047] Step 3: Adjust the chuck stroke of the tensile testing machine and cooperate with the L-shaped limit rod to keep the initial photo frame in a square shape, that is, the connecting rods of the main frame are 90° to each other. Place the edge of the cross-shaped pattern between the rubber pads 17 of the rear clamping part, and tighten the bolts on the rear clamping part 8, so that the upper clamping plate 16 and the lower clamping plate 15 clamp the pattern and fix it on the movable base 14 on.

[0048] Step 4: adjust the bolts and nuts on t...

Embodiment 2

[0052] Step 1: Prepare the test sample, cut the carbon fiber reinforced polyether ether ketone prepreg to be tested into a specified shape, the long side is 320mm, the short side is 100mm in a cross-shaped pattern, the warp and weft yarn direction of the fiber cloth is consistent with the cross direction, Wherein the carbon fiber reinforced polyether ether ketone prepreg is a prepreg prepared by electrostatic powder spraying, the reinforcing body is preferably a T300 plain weave carbon fiber cloth, the matrix is preferably Vicote 702 polyether ether ketone fine powder from Shanghai Vigers Company, and Mix 2-3% volume fraction of PTFE powder.

[0053] Step 2: Install the main frame on the tensile testing machine, install the tension-compression sensor 3 on the main frame and power on.

[0054] Step 3: Adjust the chuck stroke of the tensile testing machine and cooperate with the L-shaped limit rod to keep the main frame in a square shape, that is, the connecting rods of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com