Engineering project visual progress control system based on three-dimensional real scene

A technology for project and progress control, applied in the details of processing steps, image data processing, resources, etc., can solve problems such as inaccurate and one-sided progress control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

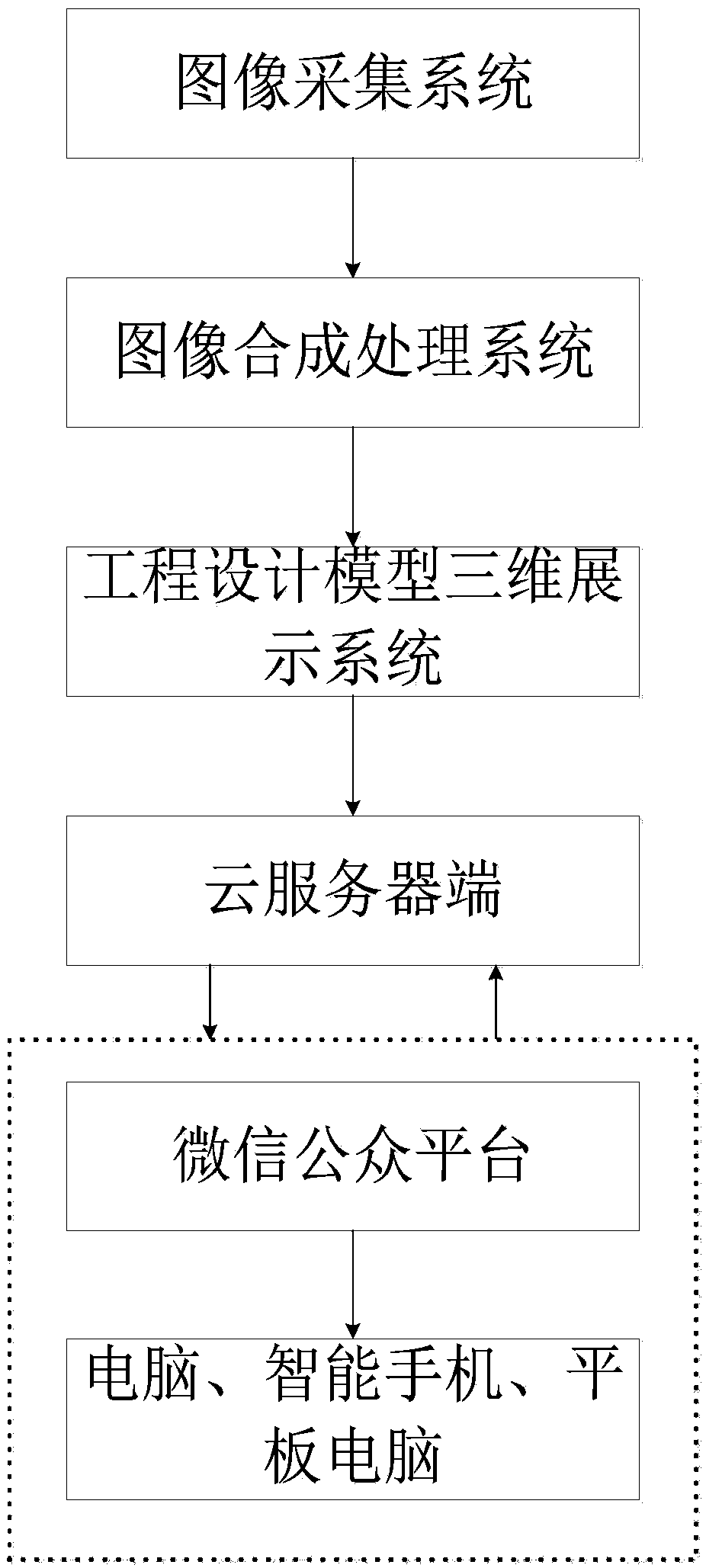

[0026] An image progress control system based on a three-dimensional real scene model, the system includes: an engineering entity image acquisition system, an image synthesis processing system, a data reporting system, an engineering design model three-dimensional display system, and a data query system.

[0027] The engineering entity image collection system includes a drone, which collects image information by taking pictures of the construction site. The drone uses the GPS global positioning system, and the GPS global positioning system carries the WGS-84 coordinate system to accurately Pick up the coordinates, find the longitude, latitude, and altitude of the specified point that is planned to be photographed, and fly to the specified point for 360-degree image capture to complete the real-life panoramic shooting of the project.

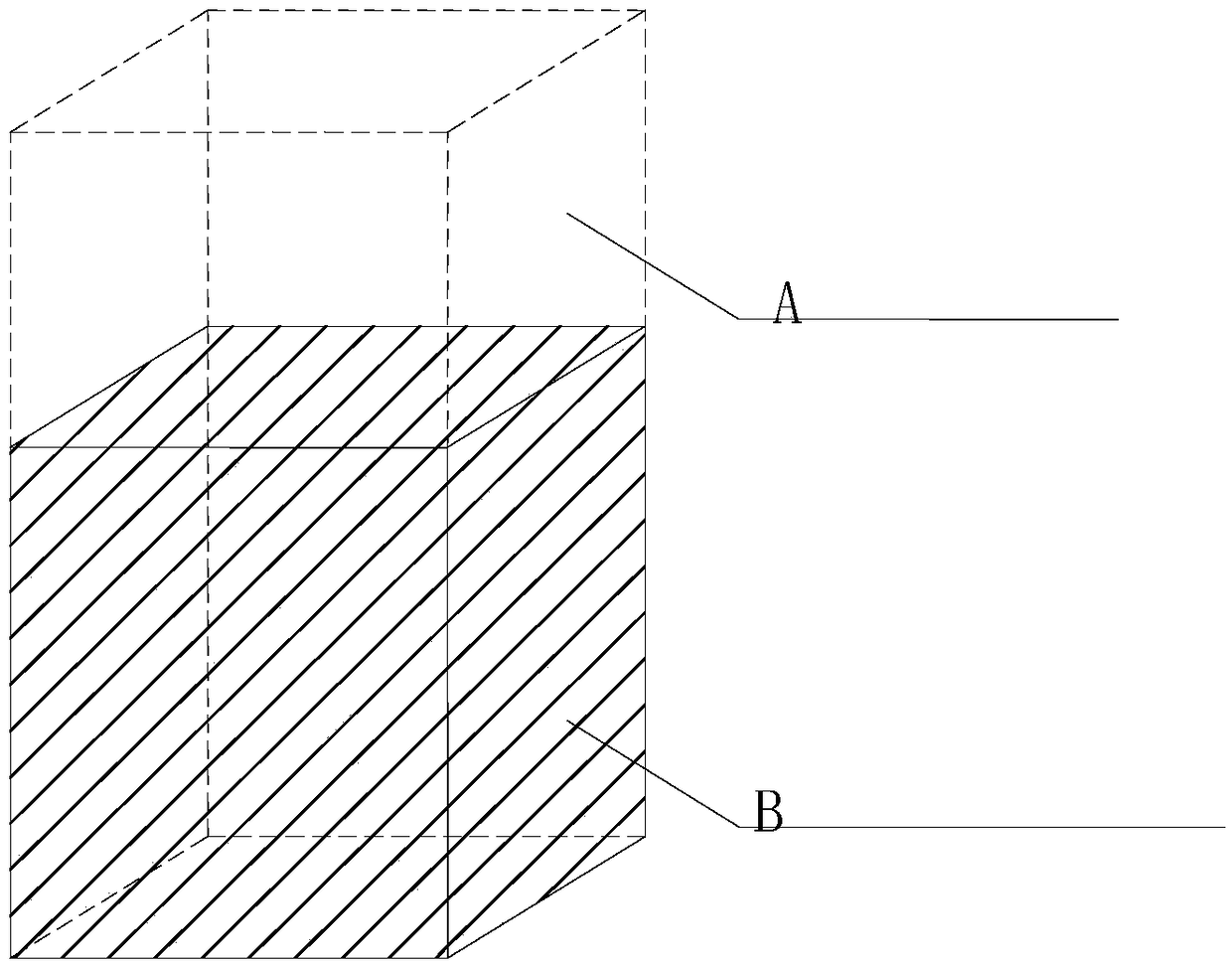

[0028] The image synthesis processing system includes image processing software, and the image processing software uses Altizure software to carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com