Automatic identification and grading method of center segregation defect in low magnification structure of continuous casting slab

A low-magnification, automatic identification technology, applied in neural learning methods, optical testing flaws/defects, analysis of materials, etc., can solve problems such as small central segregation area, cracks and oily shrinkage holes, etc., to achieve low misjudgment rate, operation The effect of short time and fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

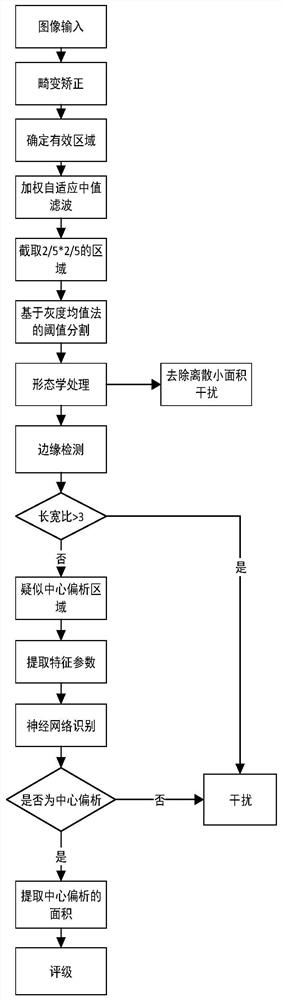

[0072] The method for automatic identification and rating of segregation defects of low-magnification structure centers in continuous casting slabs provided by the present invention includes the following steps:

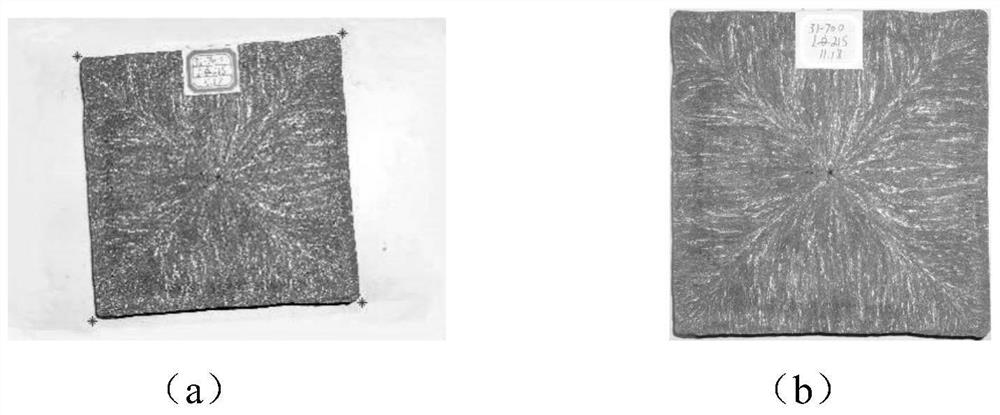

[0073] S1: Preprocessing the grayscale image of the low-magnification structure of the continuous casting slab, including distortion correction, cutting white background and filtering;

[0074] In the present invention, the grayscale histogram corresponding to the grayscale image of the low-magnification structure of the continuous casting slab is selected for defect identification. According to the histogram, the grayscale distribution on the low-magnification structure image of the continuous casting slab can be known, which further clarifies that the present invention needs to identify The central segregation position of the slab, and try to remove the interference in the continuous casting slab image in the preprocessing stage.

[0075] The grayscale image of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com