Fermented low-sugar mango jam and preparation method thereof

A fermented, mango-based technology, applied in the direction of bacteria used in food preparation, food ingredients as thickeners, food ultrasonic treatment, etc., can solve the problem of difficulty in forming a gel state, the influence of spreadability and appearance of jam products, and low-sugar mango jam Less problems, to achieve the effect of enhancing adsorption, promoting gel effect, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

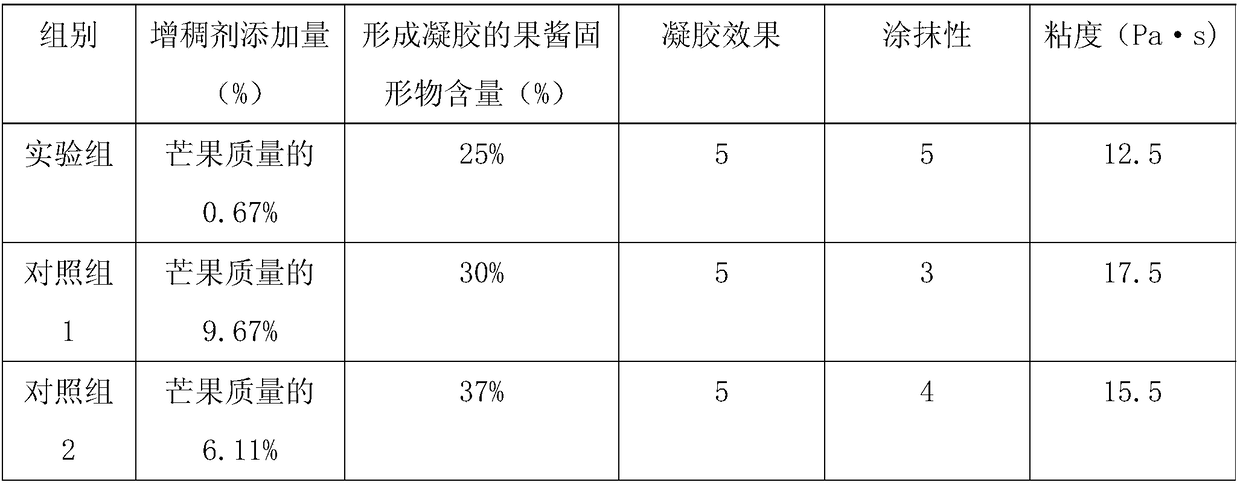

Embodiment 1

[0024] 1. Thickener preparation: in parts by weight, weigh 5 parts of sodium carboxymethylcellulose and 2 parts of apple pectin, mix and stir the apple pectin and water according to the mass ratio of 1:1 until After uniformity, add citric acid whose mass is 0.2% of the apple pectin mass and stir until uniform, then use 35KHz ultrasonic treatment for 5min, then add the weighed sodium carboxymethylcellulose and mix until uniform, then use 22KHz Ultrasonic treatment at 80°C for 3 minutes, finally dialysis and freeze-drying to obtain the thickener for future use.

[0025] 2. Weighing raw materials of fermented low-sugar mango jam: weigh 90 parts of mango, 7 parts of protein sugar and 0.6 part of thickener in parts by weight.

[0026] 3. Preparation: Apply the above-mentioned weighed raw materials to the preparation of the fermented low-sugar mango jam according to the following steps:

[0027] (1) Mango treatment: After cutting the mango into strips, blanching in 90°C water for 3...

Embodiment 2

[0032]1. Thickener preparation: in parts by weight, weigh 7 parts of sodium carboxymethylcellulose and 3 parts of apple pectin, mix and stir the weighed apple pectin and water at a mass ratio of 1:1 until uniform , add citric acid with a mass of 0.4% of the apple pectin mass and stir until uniform, then use 38KHz ultrasonic treatment for 8min, then add the weighed sodium carboxymethylcellulose and mix until uniform, then use 23KHz ultrasonic to Treat at 82°C for 5 minutes, finally dialyze and freeze-dry to obtain the thickener for future use.

[0033] 2. Weighing raw materials of fermented low-sugar mango jam: in parts by weight, weigh 98 parts of mango, 8 parts of protein sugar and 0.7 part of thickener.

[0034] 3. Preparation: Apply the above-mentioned weighed raw materials to the preparation of the fermented low-sugar mango jam according to the following steps:

[0035] (1) Mango treatment: After cutting the mango into strips, blanching in water at 92°C for 4 minutes, the...

Embodiment 3

[0040] 1. Thickener preparation: in parts by weight, weigh 8 parts of carboxymethylcellulose sodium and 5 parts of apple pectin, mix and stir the apple pectin and water according to the mass ratio of 1:1 until After uniformity, add citric acid with a mass of 0.5% of the apple pectin mass and stir until uniform, then use 40KHz ultrasonic treatment for 10min, then add the weighed sodium carboxymethylcellulose and mix until uniform, then use 25KHz Ultrasonic treatment at 85°C for 7 minutes, finally dialysis and freeze-drying to obtain the thickener for future use.

[0041] 2. Weighing raw materials of fermented low-sugar mango jam: weigh 100 parts of mango, 10 parts of protein sugar and 1 part of thickener in parts by weight.

[0042] 3. Preparation: Apply the above-mentioned weighed raw materials to the preparation of the fermented low-sugar mango jam according to the following steps:

[0043] (1) Mango treatment: After cutting the mango into strips, blanching in water at 95°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com