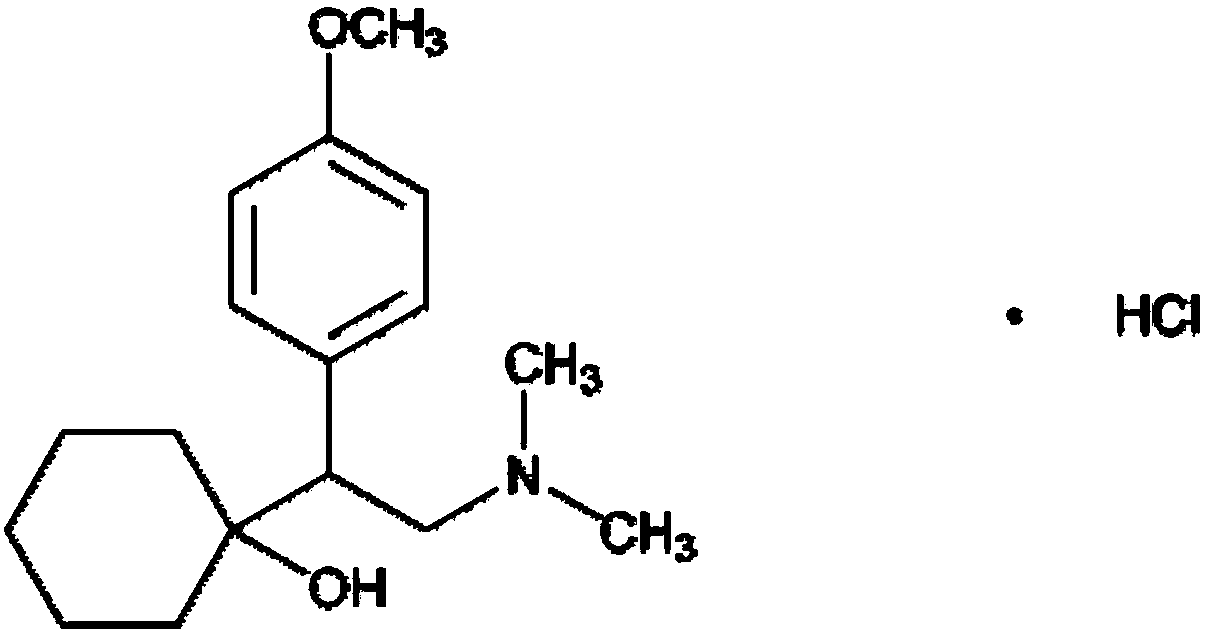

High-drug-loading venlafaxine hydrochloride sustain release pellet composition, sustained-release capsule and preparation method thereof

A technology of venlafaxine hydrochloride and sustained-release pellets, which is applied in the field of medicine and can solve the problems of too fast release of venlafaxine hydrochloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

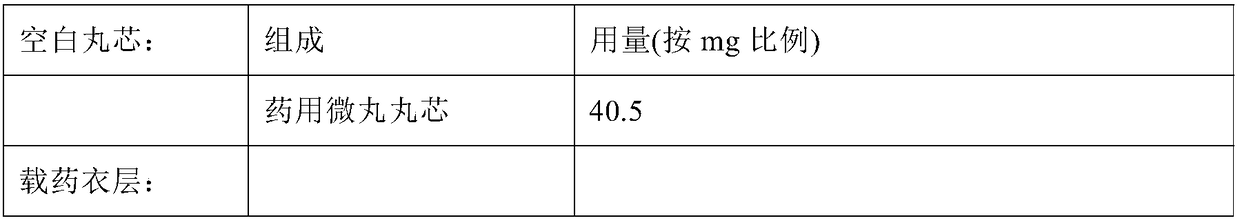

[0241] Embodiment 1: Preparation of venlafaxine hydrochloride sustained-release pellets and sustained-release capsules

[0242] formula:

[0243]

[0244]

[0245] Preparation method:

[0246] (1) Provide a blank ball core, put it in a fluidized bed coating machine (at a temperature of 42-45 degrees Celsius) to make it in a fluidized state;

[0247] (2) Wrap the drug-loaded coating layer: dissolve the adhesive in the first solvent, add venlafaxine hydrochloride that is crushed to pass through a 150 mesh sieve in advance, mix uniformly to obtain a suspension, and spray The suspension is sprayed on the blank ball core in a fluidized state in the fluidized bed coating machine, and after the spraying is completed, the fluidization is continued until the solvent is removed to obtain drug-loaded pellets; [after testing, the residual amount of the first solvent is less than 500ppm , far below the general requirement limit in this field]

[0248] (3) Wrapping the slow-relea...

Embodiment 2

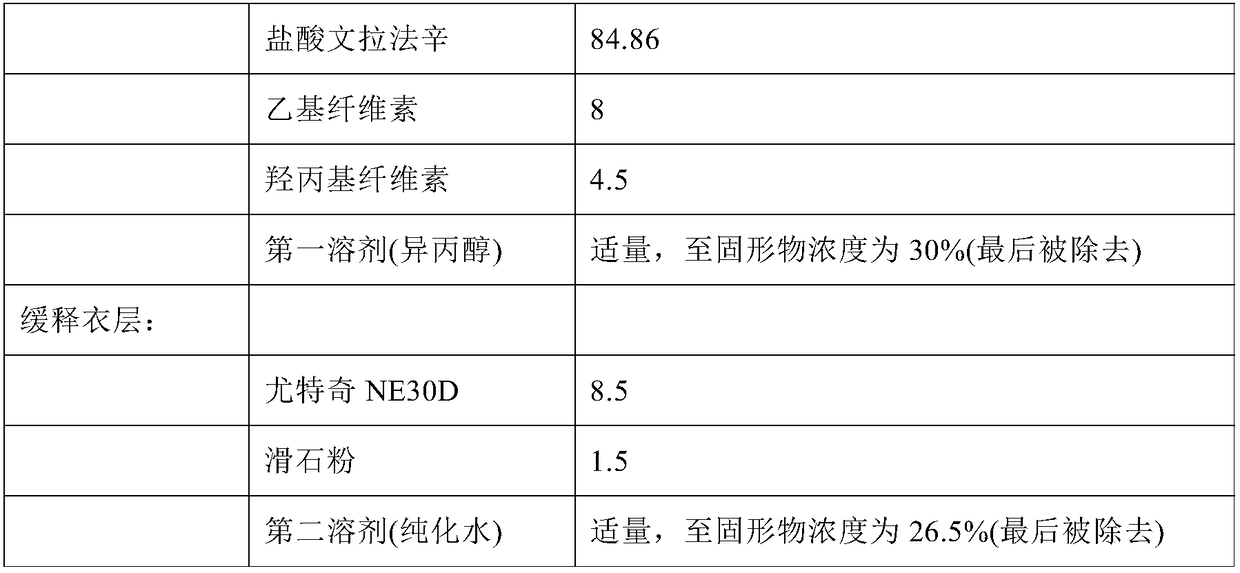

[0251] Embodiment 2: Preparation of venlafaxine hydrochloride sustained-release pellets and sustained-release capsules

[0252] formula:

[0253]

[0254]

[0255] Preparation method:

[0256] (1) Provide a blank ball core, put it in a fluidized bed coating machine (at a temperature of 42-45 degrees Celsius) to make it in a fluidized state;

[0257] (2) Wrap the drug-loaded coating layer: dissolve the adhesive in the first solvent, add venlafaxine hydrochloride that is crushed to pass through a 150 mesh sieve in advance, mix uniformly to obtain a suspension, and spray The suspension is sprayed on the blank ball core in a fluidized state in the fluidized bed coating machine, and after the spraying is completed, the fluidization is continued until the solvent is removed to obtain drug-loaded pellets; [after testing, the residual amount of the first solvent is less than 500ppm , far below the general requirement limit in this field]

[0258] (3) Wrapping the slow-relea...

Embodiment 3

[0261] Embodiment 3: Preparation of venlafaxine hydrochloride sustained-release pellets and sustained-release capsules

[0262] formula:

[0263]

[0264]

[0265] Preparation method:

[0266] (1) Provide a blank ball core, put it in a fluidized bed coating machine (at a temperature of 42-45 degrees Celsius) to make it in a fluidized state;

[0267] (2) Wrap the drug-loaded coating layer: dissolve the adhesive in the first solvent, add venlafaxine hydrochloride that is crushed to pass through a 150 mesh sieve in advance, mix uniformly to obtain a suspension, and spray The suspension is sprayed on the blank ball core in a fluidized state in the fluidized bed coating machine, and after the spraying is completed, the fluidization is continued until the solvent is removed to obtain drug-loaded pellets; [after testing, the residual amount of the first solvent is less than 500ppm , far below the general requirement limit in this field]

[0268] (3) Wrapping the slow-relea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com