Trimetazidine hydrochloride sustained-release capsule and preparation method thereof

A technology of trimetazidine and sustained-release capsules, which is applied in the field of medicine and can solve problems such as too many process parameter control points, stability to be verified, and unfavorable industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

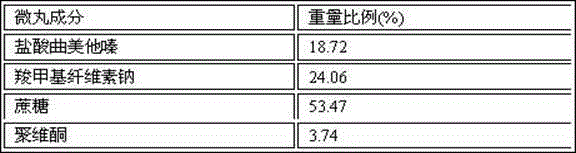

Embodiment 1

[0024]

[0025] Preparation Process:

[0026] (1) Crushing the trimetazidine hydrochloride raw material through a 100-mesh sieve;

[0027] (2) Prepare 5% povidone K30 aqueous solution;

[0028] (3) Mix the pulverized raw materials with the prescribed amount of hypromellose K15M and microcrystalline cellulose, and then use the above-mentioned binder to make a soft material;

[0029] (4) Add the soft material to the extrusion spheronizer to prepare pellets;

[0030] (5) Dry the pellets in an oven at 50°C until the moisture content is less than 3%, and then pass through a 30-mesh sieve;

[0031] (6) Filling capsules.

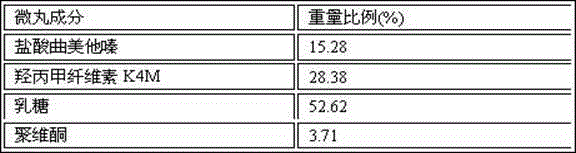

Embodiment 2

[0033]

[0034] Preparation Process:

[0035] (1) Crushing the trimetazidine hydrochloride raw material through a 100-mesh sieve;

[0036] (2) Prepare 5% povidone K30 aqueous solution;

[0037] (3) Mix the pulverized raw materials with the prescribed amount of hypromellose K4M and lactose, and then use the above-mentioned binder to make a soft material;

[0038] (4) Add the soft material to the extrusion spheronizer to prepare pellets;

[0039] (5) Dry the pellets in an oven at 50°C until the moisture content is less than 3%, and then pass through a 30-mesh sieve;

[0040] (6) Filling capsules.

Embodiment 3

[0042]

[0043] Preparation Process:

[0044] (1) Crushing the trimetazidine hydrochloride raw material through a 100-mesh sieve;

[0045] (2) Prepare 5% povidone K30 aqueous solution;

[0046] (3) Mix the pulverized raw materials with the prescribed amount of sodium carboxymethyl cellulose and sucrose, and then use the above-mentioned binder to make a soft material;

[0047] (4) Add the soft material to the extrusion spheronizer to prepare pellets;

[0048] (5) Dry the pellets in an oven at 50°C until the moisture content is less than 3%, and then pass through a 30-mesh sieve;

[0049] (6) Filling capsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com