An environmentally friendly degradable ocean ball

A marine and environmentally friendly technology, applied in the field of elastic balls, can solve the problems of not easy to grasp, rough marine balls, low compressive strength, etc., and achieve the effects of avoiding long service life, simple preparation method and good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

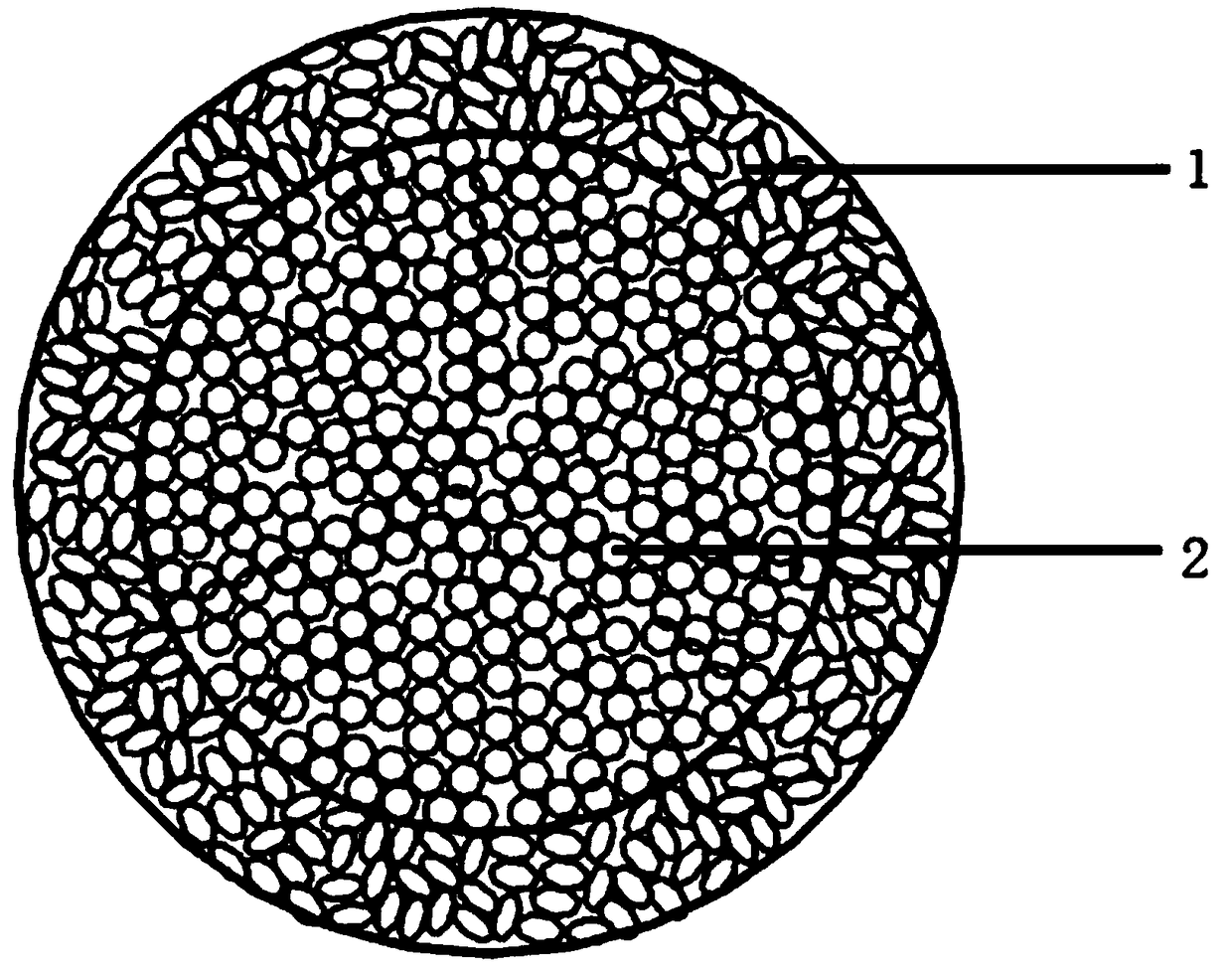

[0022] Formed by conventional polystyrene foam molding methods such as figure 1 For the ball core with a diameter of 4 cm, open the designed mold with an inner diameter of 6 cm. There is a thimble at the center of both sides of the mold, which can fix the polystyrene foam core at the center of the mold. Fill in thermoplastic polyurethane micro-foaming material particles until it is full, pass in 0.1MPa high-temperature steam, keep warm for 3 minutes, pass in cooling water to cool, open the mold, take out the sphere to get a polystyrene foam core with a diameter of 4cm and a 1cm thermoplastic polyurethane microsphere. Elastic balls of foam molding layer.

Embodiment 2

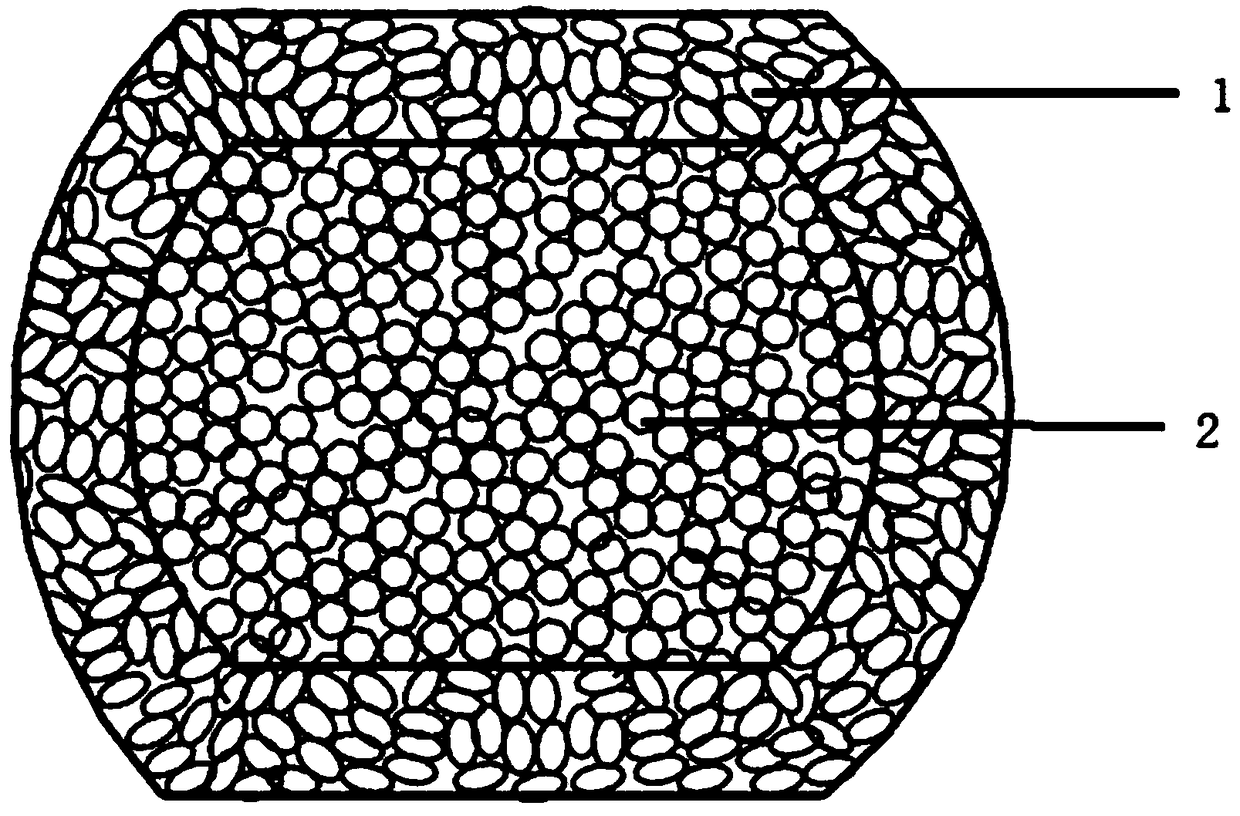

[0024] Formed by conventional polystyrene foam molding methods such as figure 2 For the core shown in the figure, open the designed mold with an inner diameter greater than 1cm of the core, fix the polystyrene foam core in the center of the mold, close the mold, and fill the thermoplastic polyurethane micro-foaming material particles from the mold material hole until it is full. Introduce high-temperature steam of 0.1MPa, keep warm for 3 minutes, infuse cooling water to cool, open the mold, and take out the sphere to obtain the following: figure 2 The shown polystyrene foam core is an elastic ball with a molding layer of 1 cm thermoplastic polyurethane micro-foam material. The use of unconventional balls can be convenient for infants and young children to grasp, and the interest of infants and young children in ocean balls can be improved.

[0025] Different from the above-mentioned embodiments, the diameter of the ball core is in the range of 1-10 cm.

[0026] Different f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap