Robot device for accurate grinding and polishing machining of optical lens lower swing machine

An optical lens and robot technology, which is used in optical surface grinders, grinding/polishing equipment, automatic grinding control devices, etc. High requirements and other problems, to achieve the effect of reliable guarantee of product processing quality, reduced labor intensity, and high precision of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

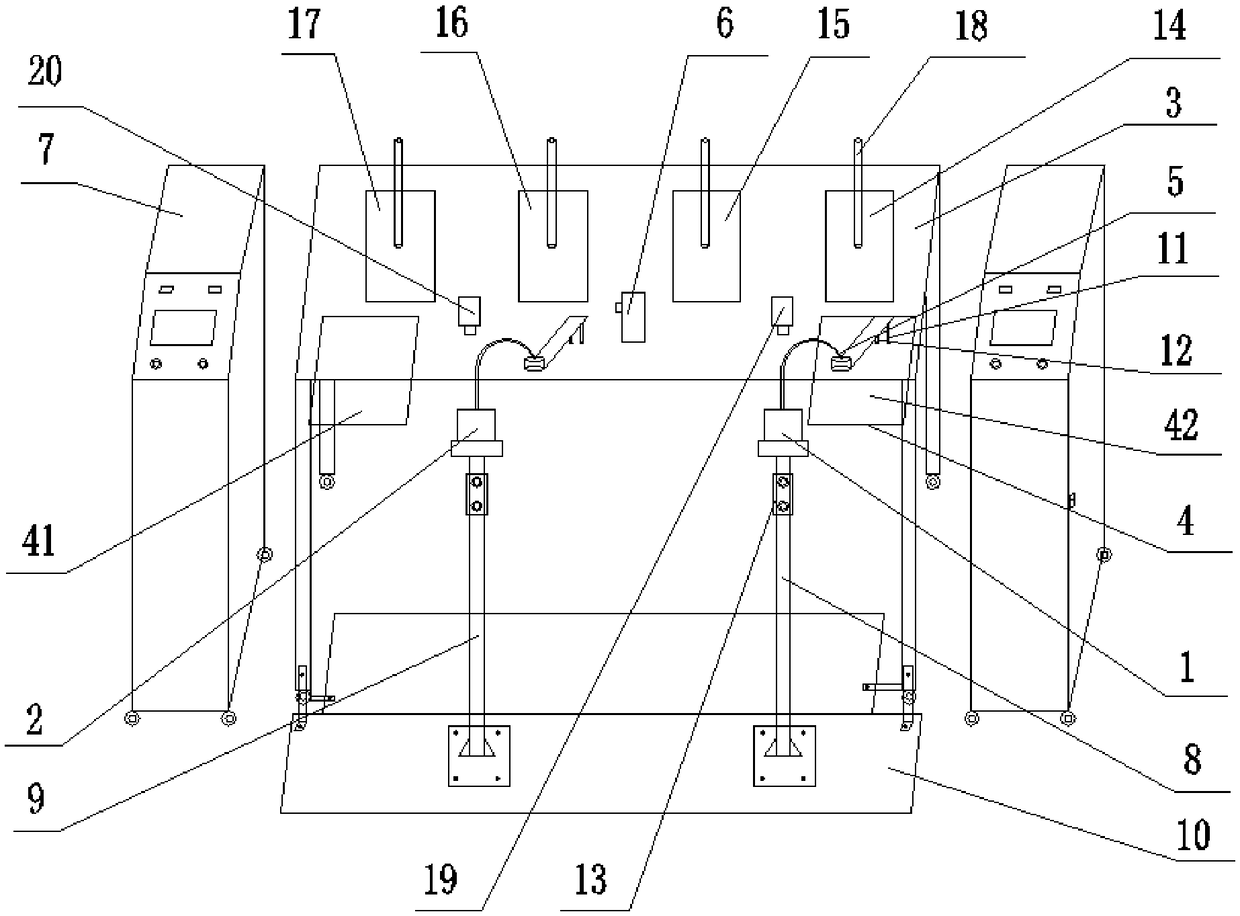

[0018] Such as figure 1 As shown, in this embodiment, a robot device for fine grinding and polishing of an optical lens hem machine includes a first plane joint robot 1, a second plane joint robot 2, a hem machine 3, a tray storage stand 4, and a plane joint robot Picking and discharging mechanism 5, lens turning mechanism 6 and control cabinet 7, the first planar articulated robot 1 is fixedly connected above the first column 8, and the second planar articulated robot 2 is fixedly connected above the second column 9 , the first column 8 and the second column 9 are all fixedly connected to the base plate 10, the body of the hem machine 3 is in the shape of a cuboid, the base plate 10 is fixedly connected to the lower end of the body of the hem machine 3, and the tray is stored...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com