An air bag type pantograph closed-loop control device

A closed-loop control and pantograph technology, which is applied in current collectors, electric vehicles, power collectors, etc., can solve problems such as separation of pantographs from catenary, pantograph-catenary accidents, and large lift of contact wires, etc. The quality of network flow and the effect of ensuring safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

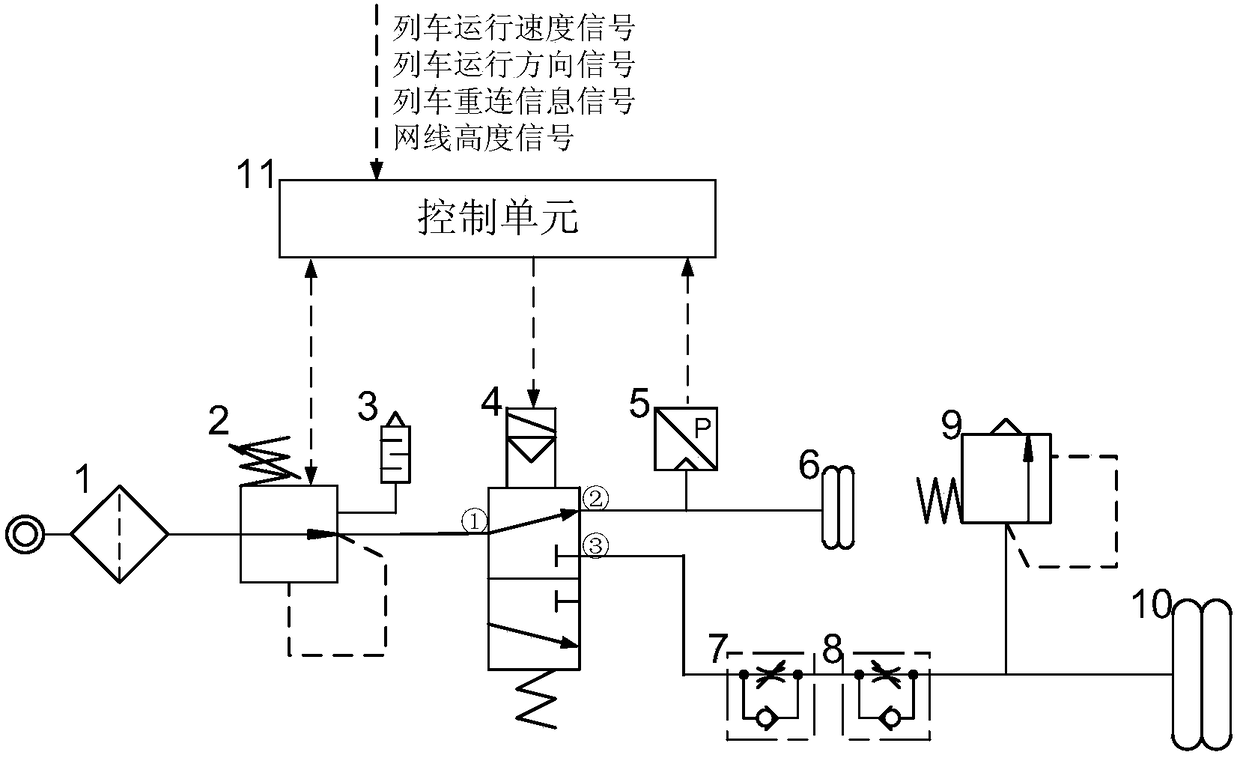

[0031] The pantograph control device uses the bow head airbag 6 and the pressure sensor 5 to detect the contact force between the pantograph and the catenary, and uses closed-loop control to adjust the pantograph-catenary contact force. The control device has the advantages of small adjustment error of the pantograph-catenary contact force and strong ability to suppress interference, thereby reducing energy consumption, prolonging the service life of the pantograph-catenary, improving the current receiving performance, and ensuring the safe and reliable operation of the train.

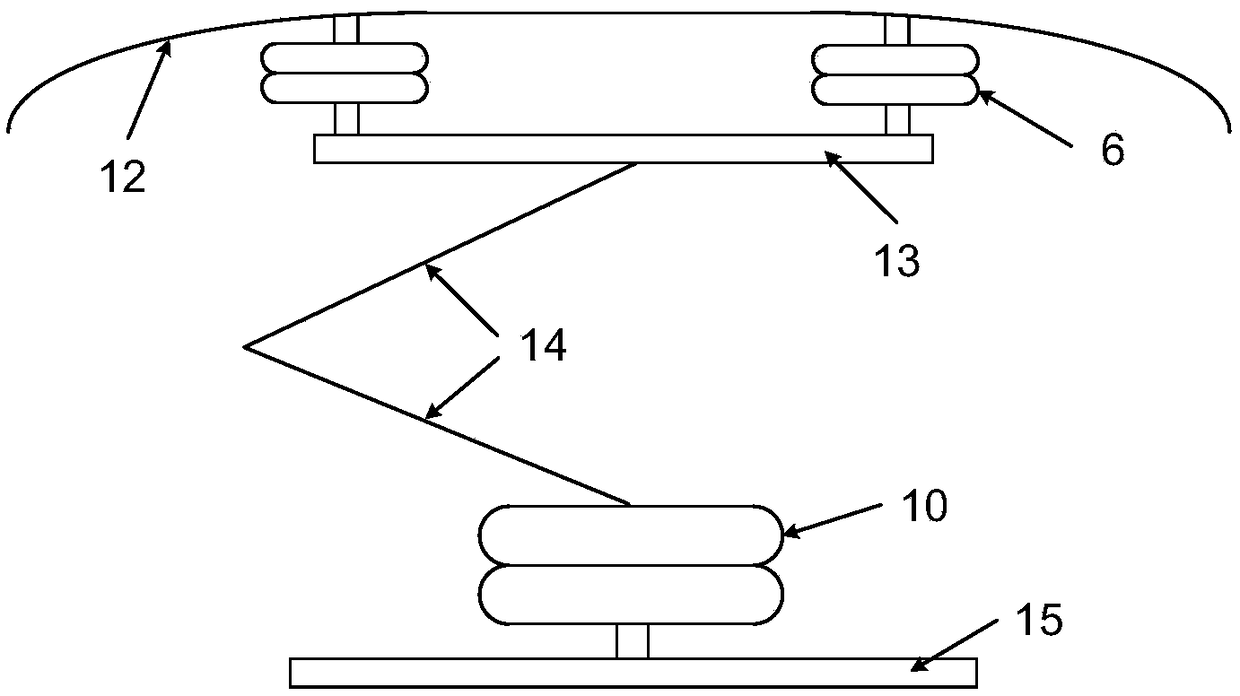

[0032] Such as figure 1 , figure 2 As shown, the pantograph control device includes an air filter 1, an electronically controlled pressure regulating valve 2, a muffler 3, a reversing solenoid valve 4, a bow throttle valve 7, a bow throttle valve 8, and a safety valve 9 . The bow airbag 10 also includes: a pressure sensor 5, a bow airbag 6 and a control unit 11;

[0033] The pantograph includes a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com