A roller mechanism for agv car and agv car

A drum and motor transmission technology, applied in the field of mechanical transmission, can solve the problems of small quantity of products, accumulation of unfavorable quality and light products, low application rate of batch transmission, etc., to achieve the effect of improving work efficiency, ensuring integrity, and simplifying the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

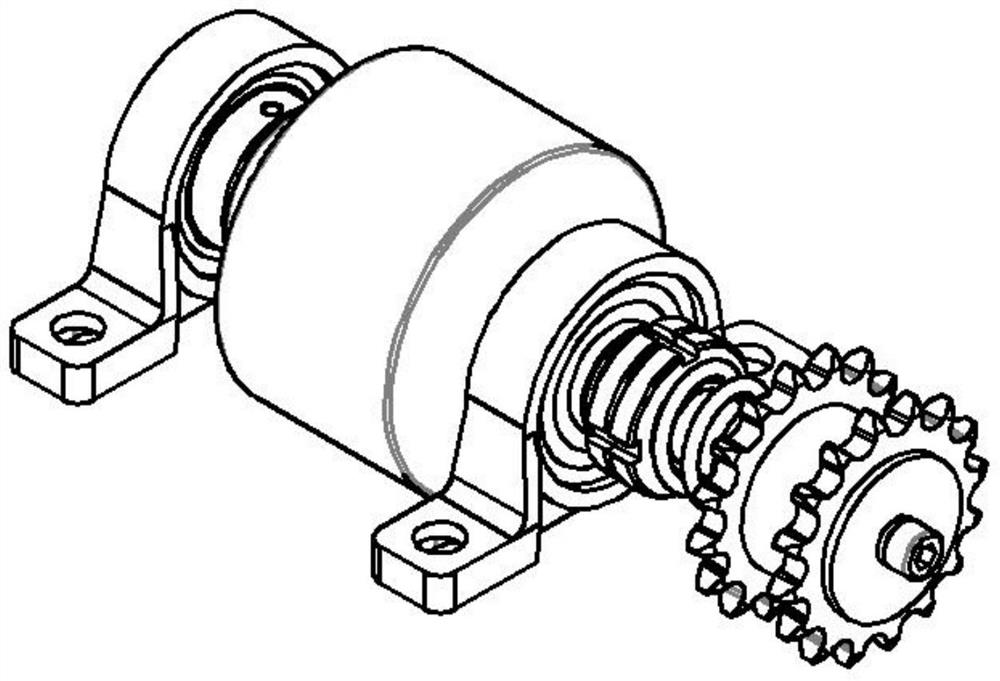

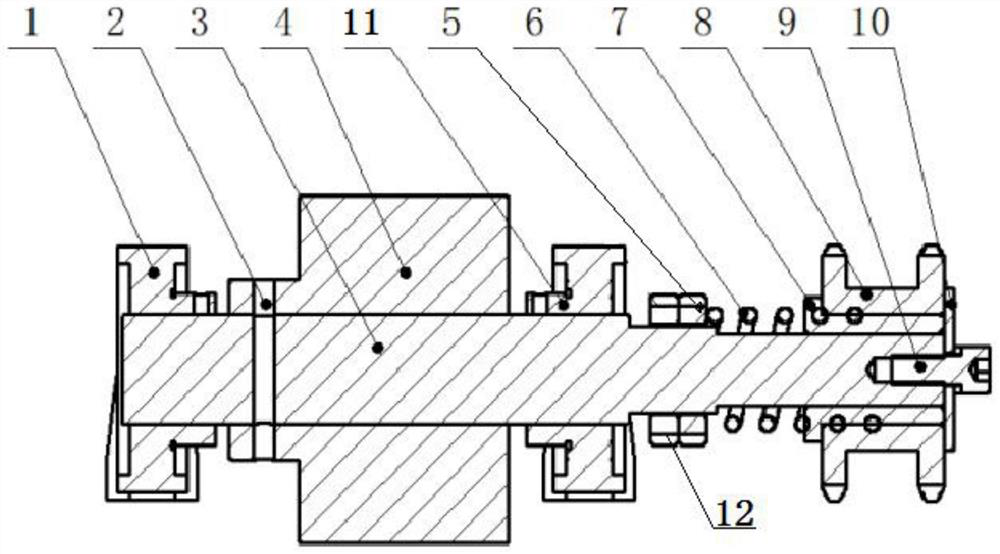

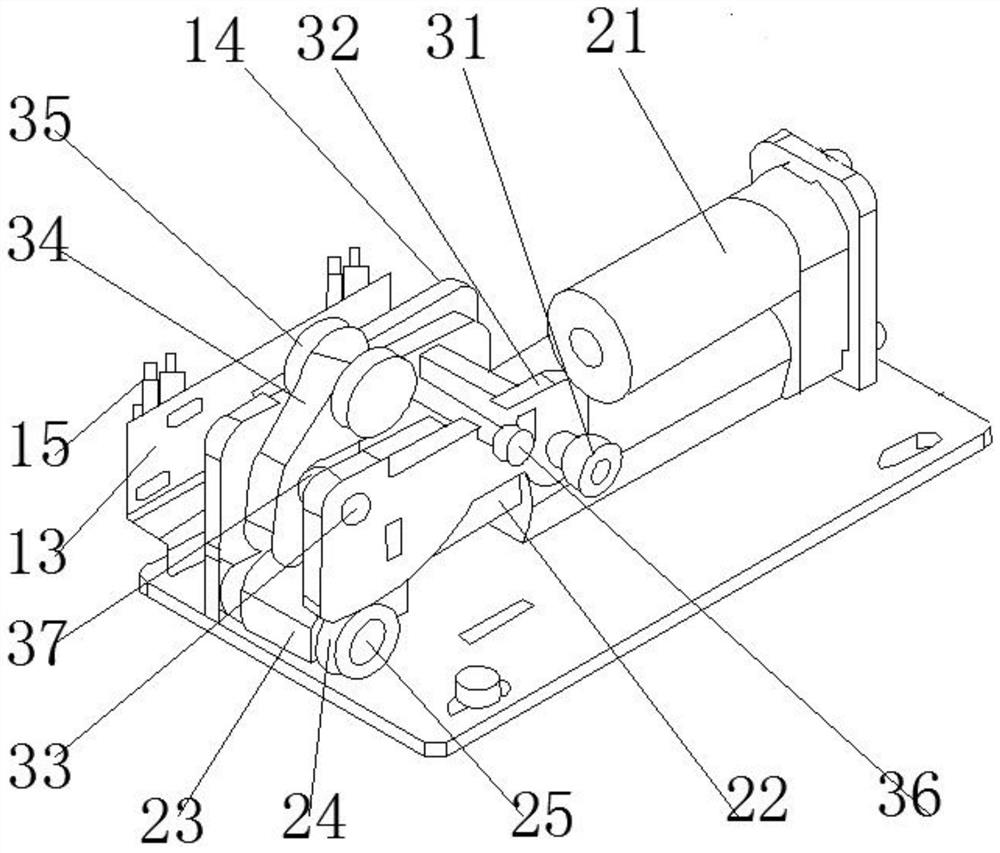

[0027] figure 1 It is a schematic diagram of a roller mechanism for an AGV car according to the present invention, figure 2 It is a cross-sectional view of a roller mechanism for an AGV car of the present invention. As shown in the figure, a roller mechanism for an AGV car includes a transmission shaft 3 and a roller 4 for transporting goods. The transmission shaft 3 is along the axial direction Three sections of cylinders with decreasing diameters, the end of the drum 4 is fixedly connected to the section with the largest diameter in the transmission shaft 3 through the spring pin 2 penetrating laterally, and the end of the transmission shaft 3 with the smallest diameter is provided for providing the rotation of the transmission shaft 3 The motor drive wheel for traction, the motor drive wheel is connected to the output end of the external motor through a transmission belt, a copper sleeve 7 is arranged between the axis of the motor drive wheel and the drive shaft 3, and the...

Embodiment 2

[0034] This case also discloses a roller transmission method for an AGV car, including the following steps:

[0035] S1. When the goods are in the transportation state, the traction force of the motor is applied to the transmission shaft 3 through the motor drive wheel (that is, the double-row sprocket 8 mentioned above), the spring 6 and the drive nut 5 to drive the drum 4 to rotate, so that the goods are pulled from the drum. 4. One-way transport on the side wall;

[0036] Ideally, the axes of the motor drive wheel, copper sleeve 7, spring 6, and drive nut 5 are in a collinear state

[0037] S2. When the cargo transportation process is blocked and the cargo itself is in a static state, a relative friction force is generated between the cargo and the roller 4, and the relative friction force between the cargo and the roller 4 is greater than the static friction force between the spring 6 and the copper sleeve 7. The spring 6 and the copper sleeve 7 appear to move relative to...

Embodiment 3

[0041] The difference between this embodiment and the first embodiment and the second embodiment is that the fixed nut 12 and the transmission nut 5 in the above embodiment are combined into one, and changed into an open nut, and bolts are added to the side of the open nut, then the transmission Some components include split nut, spring 6, and motor drive wheel. Spring 6 is in conflict with the end face of the copper sleeve 7 embedded in the motor drive wheel and the end face of the split nut respectively. When adjusting the friction force, open the bolt on the split nut and adjust it to a suitable position. Tighten the bolts on the split nut at the same time. Compared with the double nut adjustment, this method can reduce the space occupied by the parts to a certain extent.

[0042] Adopting the technical solution of the present invention, through the interference fit between the copper sleeve and the double-row sprocket, the relative friction between the copper sleeve and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com