A Lubricity Experimental Device and Experimental Method for Horizontal Well Drilling Considering Cuttings Bed

An experimental device and cuttings bed technology, applied in the field of horizontal well drilling lubricity experimental devices, can solve the problems of lower drilling efficiency, failure to consider the frictional resistance between the drill string and the cuttings bed, and the reduction of drilling fluid lubrication performance, and improve the evaluation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

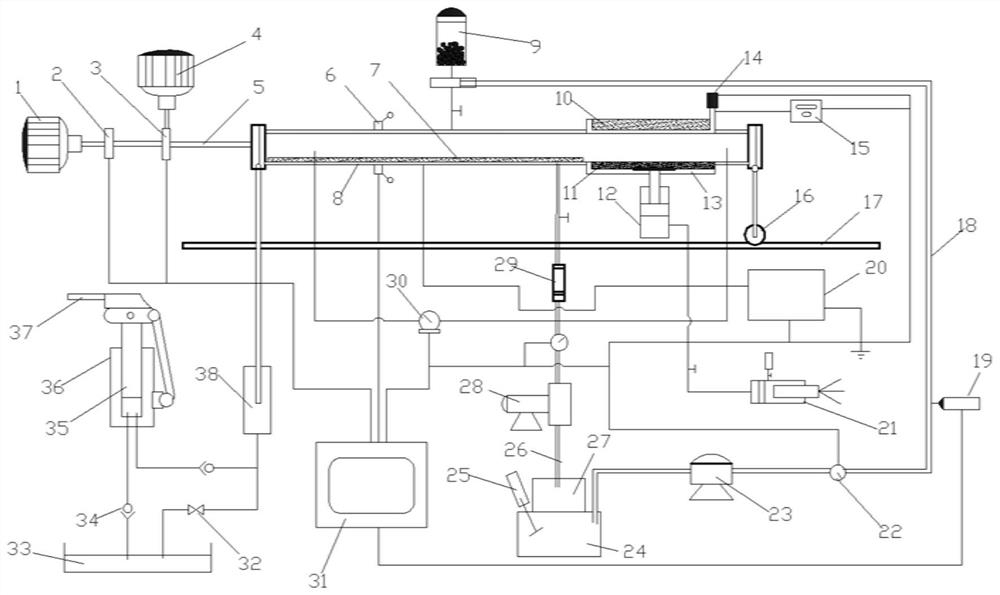

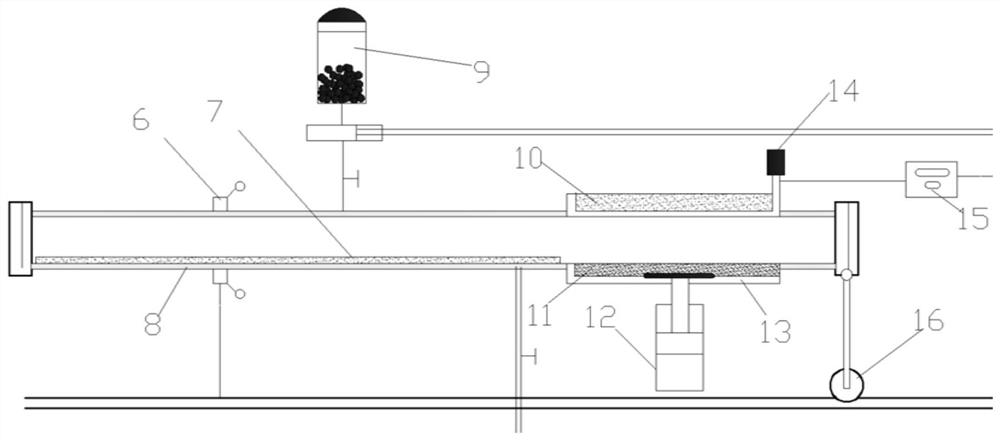

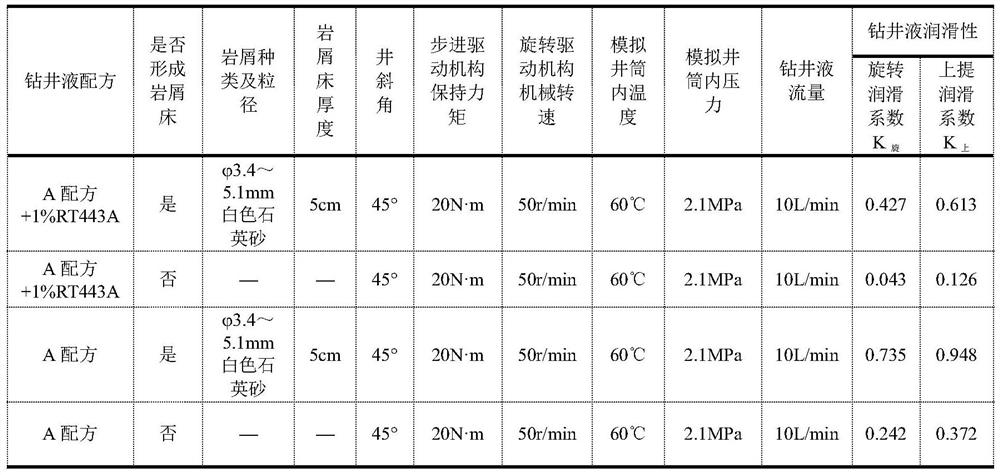

[0030] Such as figure 1 As shown, a horizontal well drilling lubricity experiment device considering the cuttings bed includes a simulated wellbore, a hydraulic lifting device, a drilling fluid supply system, a pressure mechanism, and a calculation and display unit, wherein the tolerance temperature of the simulated wellbore is above 200 °C , the withstand pressure is above 30MPa, and the composite drilling method of rotary drilling and sliding drilling can well simulate the cuttings bed state under actual working conditions. Therefore, the composite drilling experiment system can simulate the lubrication performance of drilling fluid under certain temperature and pressure in deep well drilling closer to the actual working conditions on site.

[0031] The specific connection structure of the experimental device and the functions of each compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com