Atomic gas chamber glass bulb pressure resistance test device and test method

A technology of withstand voltage test and atomic gas chamber, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of potential safety hazards of testers, sensitivity to vibration, broken and splashed, etc., to achieve guarantee The effect of testing personnel and equipment safety, preventing safety injuries, and improving testing efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

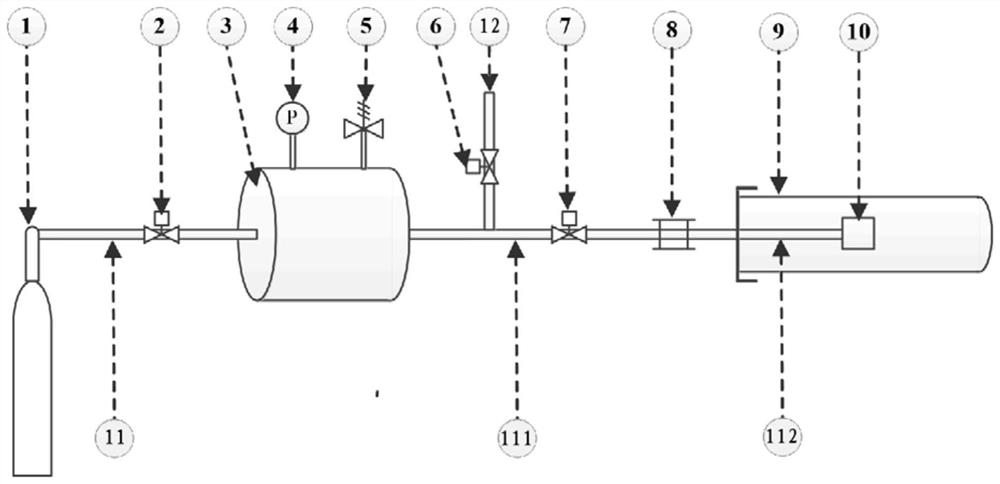

[0035] Such as figure 1 , in this embodiment, the atomic gas chamber glass bulb pressure test device includes: high pressure gas cylinder 1, ball valve I2, pressure cylinder 3, pressure sensor 4, safety valve 5, ball valve II6, ball valve III7, stainless steel joint 8 , Explosion-proof cylinder 9, gas chamber glass bulb 10, gas pipeline 11 and exhaust pipeline 12. Among them, the outlet of the high-pressure gas cylinder 1 is connected to one end of the gas pipeline 11, and the other end passes through the explosion-proof cylinder 9 and then connects to the glass bulb of the gas chamber 10; The direction from the gas cylinder 1 to the gas chamber glass bulb 10 is arranged on the gas pipeline 11 in sequence; the pressure sensor 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com