Silencer for air conditioning and air conditioner

A technology for mufflers and air conditioners, applied in the field of air conditioners, can solve the problems of complex structure, narrow sound-absorbing frequency band, poor sound-absorbing effect, etc., and achieve the effect of improving user experience, increasing sound-absorbing frequency bands, and reducing high-frequency noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

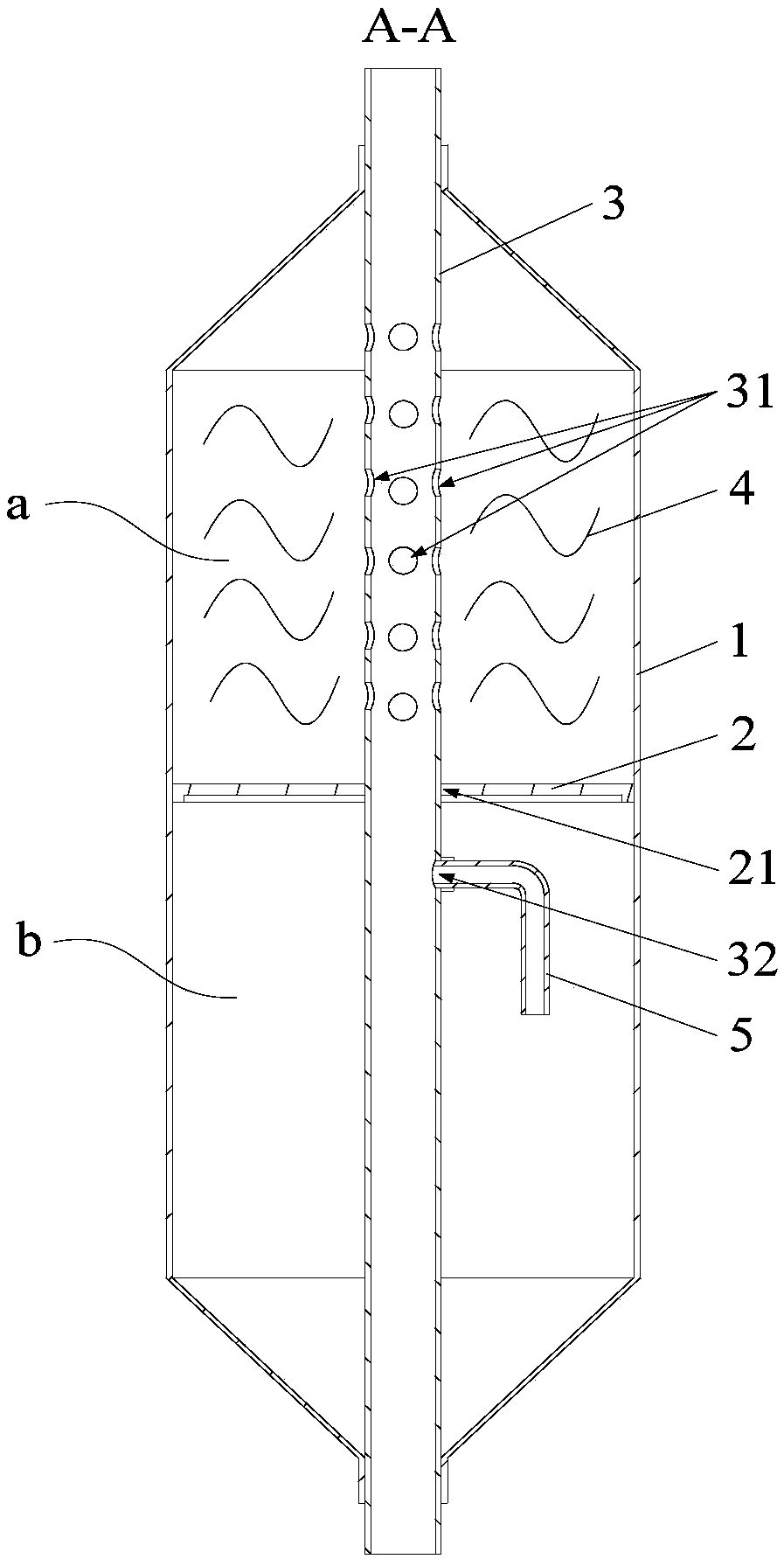

[0054] One end of the inner pipe 3 is an air inlet end, and the other end is an air outlet end, the air inlet end is located in the first pipe section, and the air outlet end is located in the second pipe section.

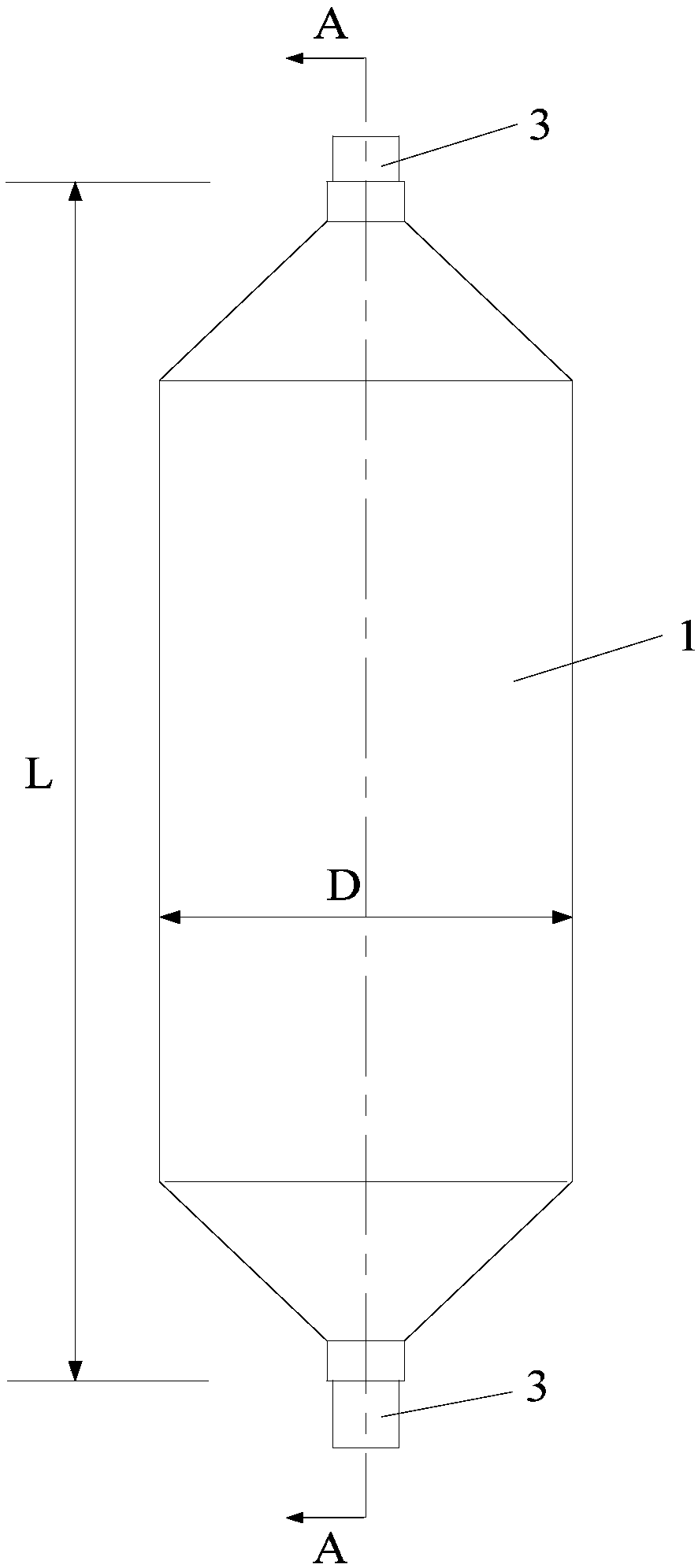

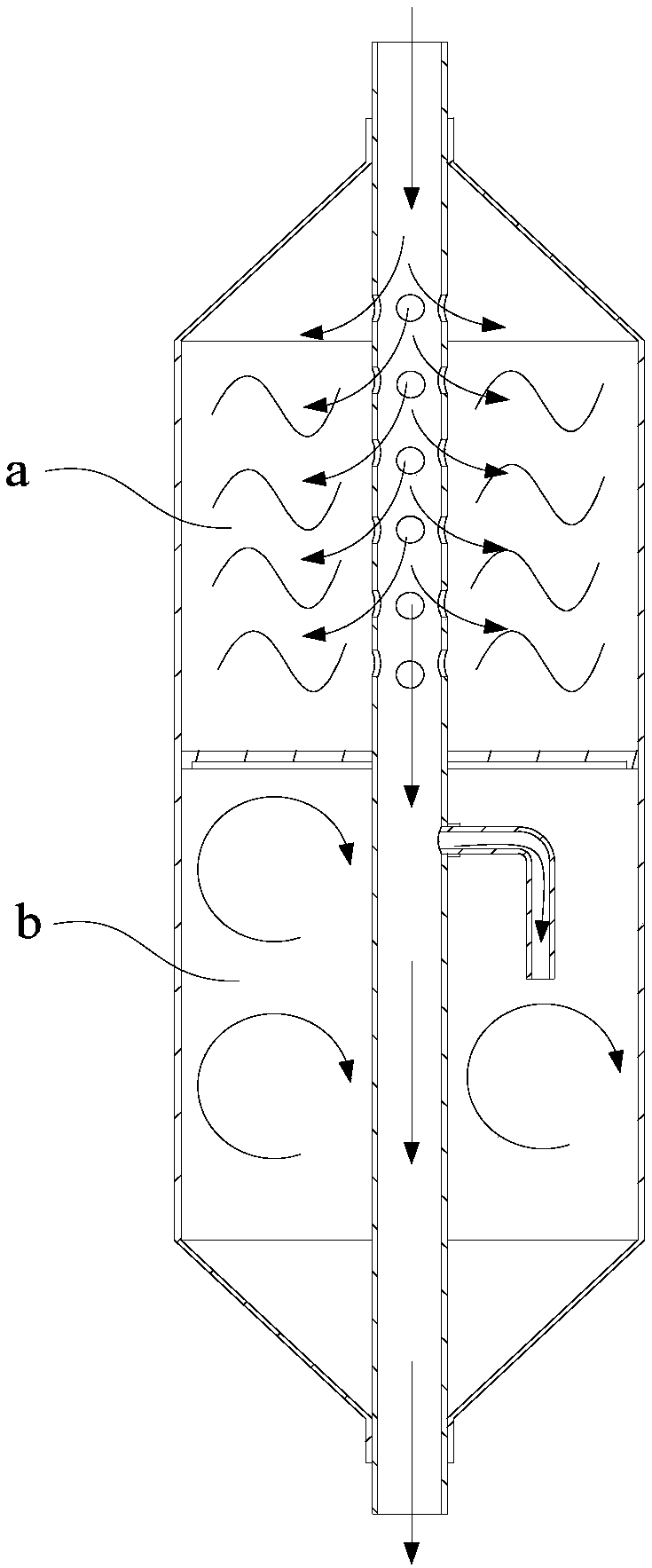

[0055] Specifically, the muffler for an air conditioner includes an outer cylinder 1, an inner pipe 3, an inner partition 2, and sound-absorbing materials. In 1 / 2 room, an array of small holes (namely the first through hole 31) is opened on the tube, and the end of the array of small holes is opened. The inner partition 2 and the outer cylinder 1 form a sound-absorbing cavity a, and the sound-absorbing cavity a is filled with sound-absorbing materials; the inner tube 3 At the air outlet end, one or two small holes (that is, the second through hole 32) are opened on the pipe, and at the end of the small hole, the inner partition 2 and the outer cylinder 1 form the Helmholtz resonance chamber b; the air flow enters through the inner pipe 3 The air end enters the muff...

Embodiment 2

[0057] Such as Figure 1 to Figure 3 As shown, the difference between the second embodiment and the first embodiment is that the resonance tube 5 is connected to the second through hole 32, and the resonance tube 5 is entirely located in the Helmholtz resonance cavity b.

[0058] By connecting the resonance pipe 5 at the second through hole 32 of the second pipe section of the inner pipe 3, a specific frequency can be designed by adjusting the length of the resonance pipe 5, thereby combining the sound absorption and noise reduction of the sound absorption chamber a to eliminate the noise of a wider frequency band , so as to achieve the purpose of reducing or eliminating noise; preferably, the resonance tube 5 is inserted into the second through hole 32 and welded to the second section of the inner tube 3 .

[0059] Specifically, the air conditioner muffler includes an outer cylinder 1, an inner pipe 3, an inner partition 2, a sound-absorbing material 4, and a resonance pipe 5...

Embodiment 3

[0061] One end of the inner pipe 3 is an air inlet end, and the other end is an air outlet end, the air inlet end is located in the second pipe section, and the air outlet end is located in the first pipe section.

[0062] Specifically, the muffler for an air conditioner includes an outer cylinder 1, an inner pipe 3, an inner partition 2, and sound-absorbing materials. The second through hole 32), the small hole end is opened, the inner partition 2 and the outer cylinder 1 form the Helmholtz resonance chamber b; the inner tube 3 is the gas outlet end, and an array of small holes (i.e. the first through hole 31) is opened on the tube, At the end of an array of small holes, the inner partition 2 and the outer cylinder 1 form a sound-absorbing chamber a, and the sound-absorbing chamber a is filled with sound-absorbing materials; the airflow enters the muffler through the air inlet of the inner pipe 3, and part of the airflow enters through the small holes on the inner pipe 3 Helm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Middle diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com