Insulation performance testing device, insulation performance testing method and application

The technology of a testing device and a testing method, which is applied in the field of thermal insulation performance testing devices, can solve problems to be studied, thermal insulation performance testing of thermal insulation products, etc., and achieve the effects of high maturity, wide industrial application prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

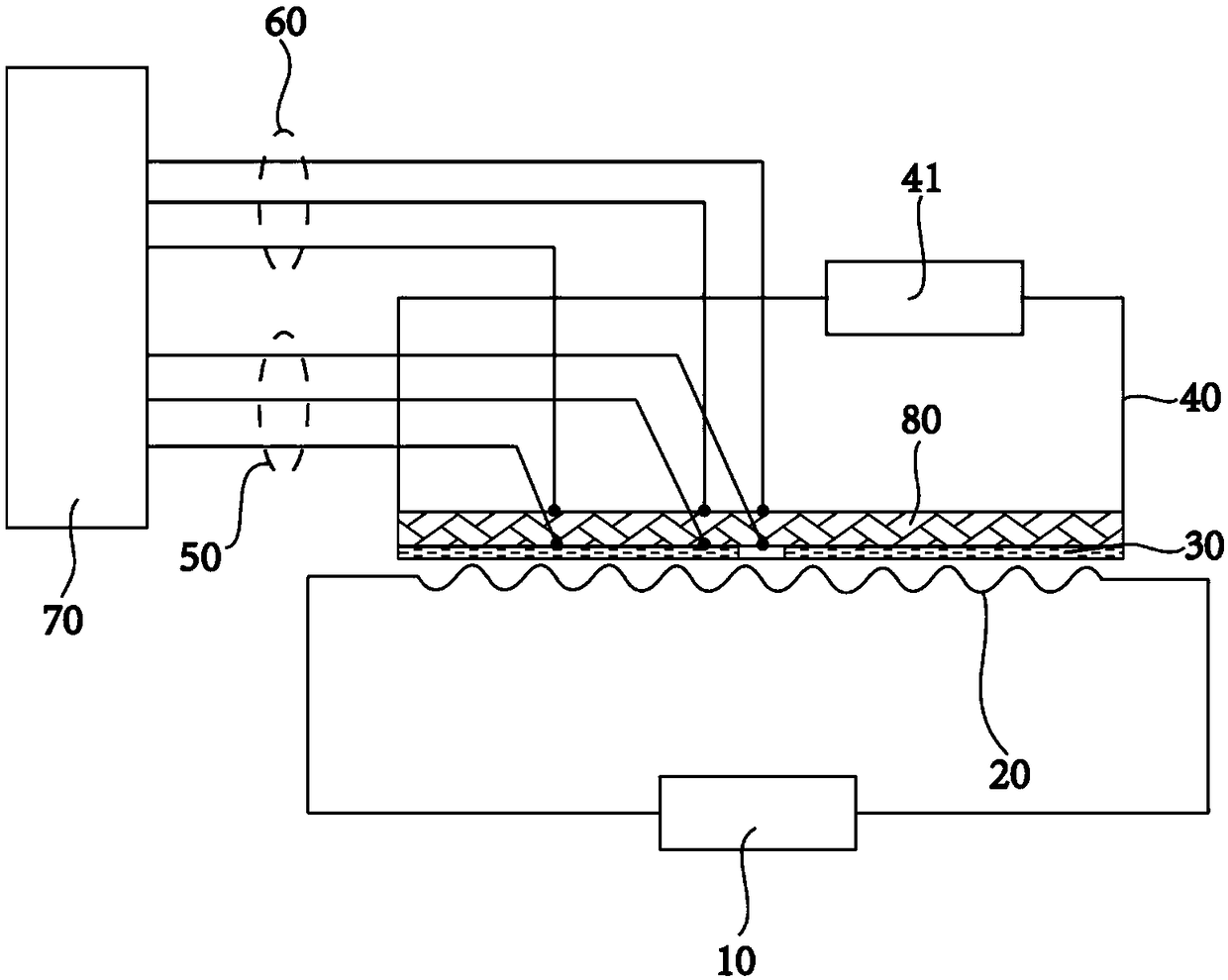

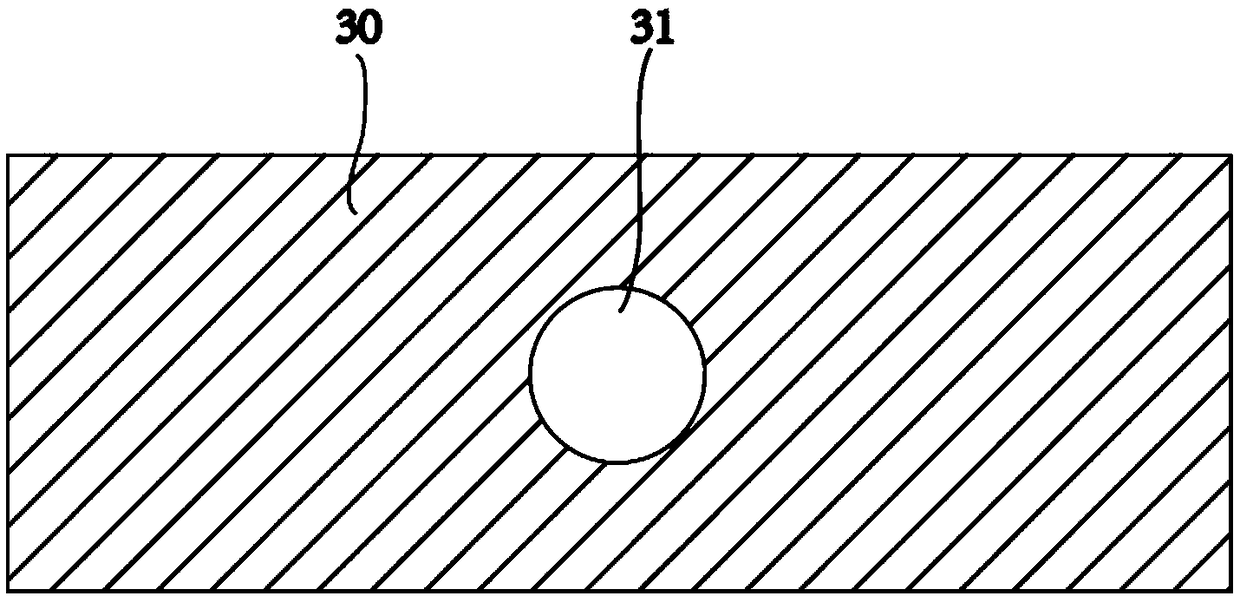

[0092] This embodiment provides a heat insulation performance testing device, including a heating temperature control device, a heater, a heat transfer plate, a cover plate, a first thermocouple, a second thermocouple and a temperature recorder;

[0093] The heating and temperature control device is electrically connected with the heater. The heater is provided with a heat transfer plate. The heat insulation sample is placed on the heat transfer plate and fits the heat transfer plate. The cover plate can be covered on the heat transfer plate so that The heat insulation sample is in a relatively closed space, and an environmental temperature control device is provided on the cover plate, and the environment temperature control device is used to control the temperature of the surface of the heat insulation sample away from the heat transfer plate;

[0094]A first thermocouple is installed on the surface of the heat insulation sample close to the heat transfer plate, and a second ...

Embodiment 2

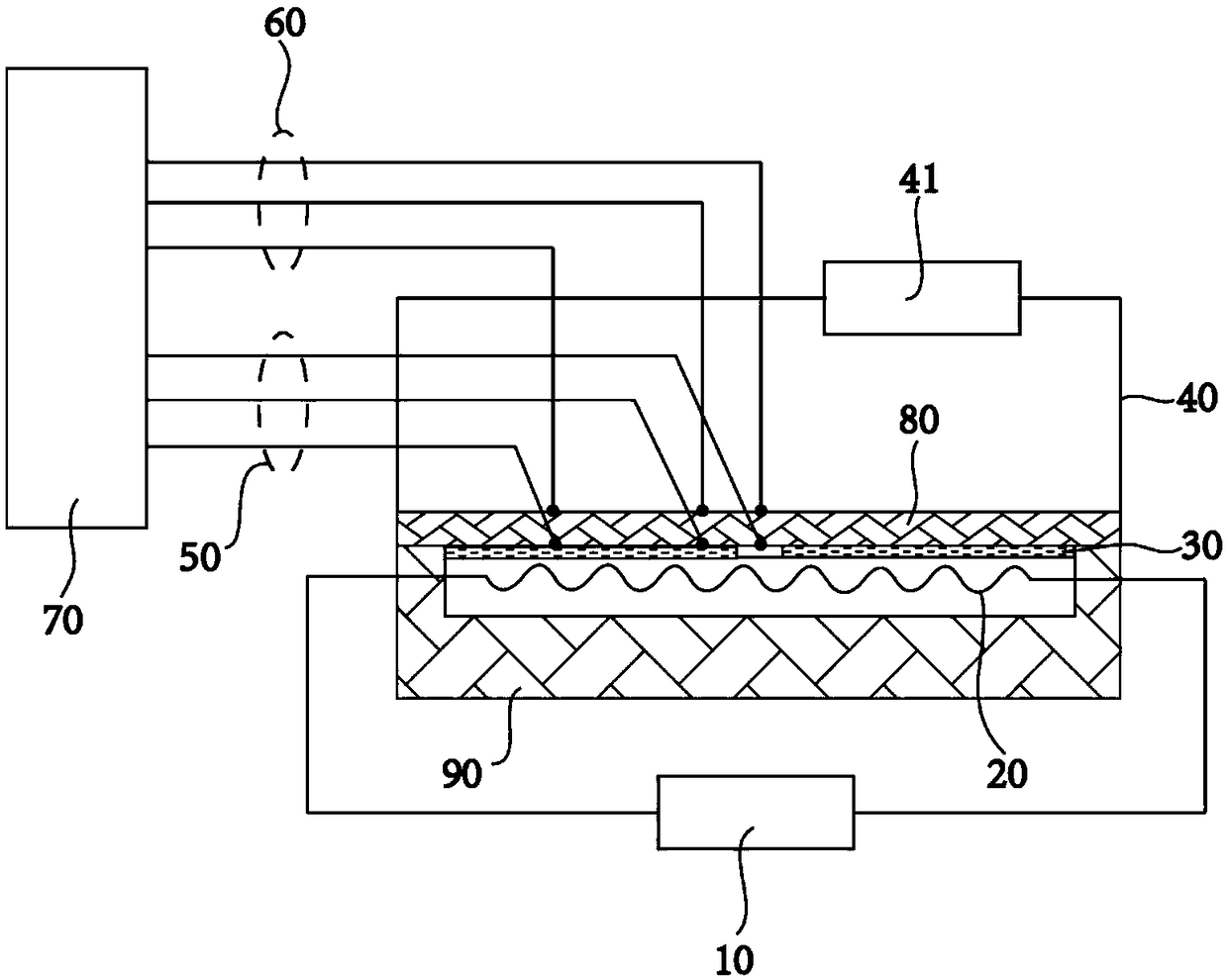

[0098] This embodiment provides a heat insulation performance test device, which is a further improvement of embodiment 1. In addition to the structures described in embodiment 1, the heat insulation performance test device also includes a heat insulation base;

[0099] The heat-insulating base is arranged below the heater and a groove is also arranged on the heat-insulating base, the heater is located in the groove on the heat-insulating base, and the heat transfer plate is located at the opening of the groove, that is, the heat transfer plate and the groove It is surrounded by a closed space, the heater is located in the closed space, the heat insulation sample is set on the heat insulation base, and the side of the heat transfer plate close to the heat insulation sample is at the same level as the upper surface of the heat insulation base.

[0100] Among them, the heating and temperature control device adopts ZKL-2000 intelligent temperature control system for temperature co...

Embodiment 3

[0102] This embodiment provides a heat insulation performance test method, using the heat insulation performance test device in Example 1 to test the heat insulation performance of the heat insulation sample, including the following steps:

[0103] (a) Provide the heat insulation sample and the corresponding heat transfer plate, place the heat transfer plate on the heater, and place the heat insulation sample to be tested on the heat transfer plate (make sure that the heat insulation sample is attached to the heat transfer plate combine);

[0104] (b) Cover the cover plate on the heat transfer plate, and control the temperature of the surface of the heat insulation sample away from the heat transfer plate through the environmental temperature control device;

[0105] (c) Turn on the heating temperature control device and the heater, heat the heat-insulated sample by forming a non-uniform temperature field on the heat transfer plate, and use the first thermocouple and the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com