A control system for offshore wind power step-up dry-type transformer

A dry-type transformer and control system technology, applied in control/regulation systems, non-electric variable control, electrical program control, etc., can solve the problems of high maintenance cost, difficulty in real-time data control, poor economic benefits, etc., and reduce maintenance costs. , The effect of reducing the frequency of going to sea and reducing the cost of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

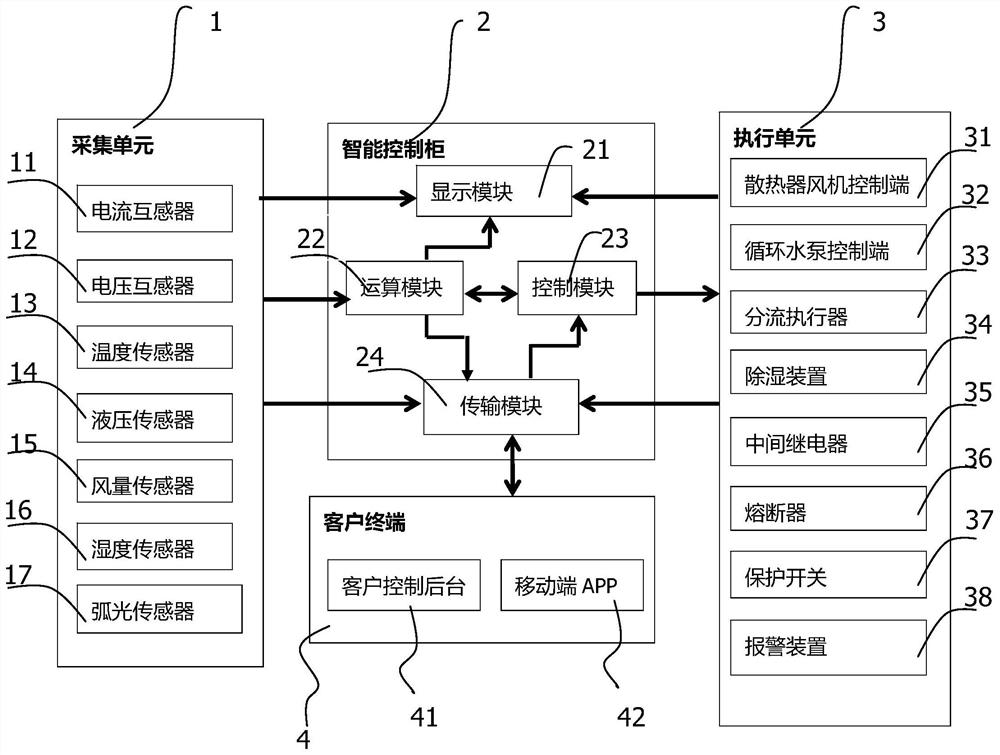

[0021] Such as figure 1 Shown is an offshore wind power step-up dry-type transformer control system of the present invention, including: an acquisition unit 1, an intelligent control cabinet 2, an execution unit 3 and a client terminal 4; the acquisition unit 1 includes a current transformer 11 and a voltage transformer 12 , temperature sensor 13, hydraulic sensor 14, air volume sensor 15, humidity sensor 16 and arc light sensor 17 and other acquisition components are used to collect real-time operating data and working environment data of the transformer; the intelligent control cabinet 2 includes a display module 21, an operation module 22, The control module 23 and the transmission module 24 are mainly used to display the data obtained by the acquisition unit 1 and the execution status of the execution unit 3, perform logical operations on the data obtained by the acquisition unit 1 and the environmental data, and use the calculation results as a judgment basis to issue cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com