A lithium ion battery film for additive composition and a non-aqueous electrolyte and a lithium ion battery

A non-aqueous electrolyte, lithium-ion battery technology, used in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of film breakage, low electrolyte conductivity, and high electrolyte viscosity. The effect of improving service life, good cycle performance and rate discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] (1) Preparation of non-aqueous electrolyte

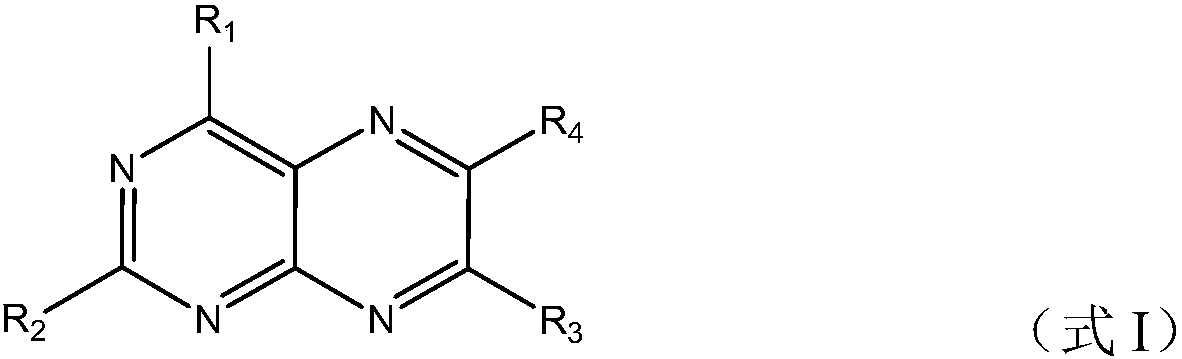

[0080] The pteridine type compound that present embodiment adopts is:

[0081] The sulfone used in this example is

[0082] Lithium hexafluorophosphate (LiPF 6 ) is dissolved in ethylene carbonate (EC) and diethyl carbonate (DEC), then add pteridine type compound and sulfone, mix uniformly, thus obtain the non-aqueous electrolytic solution according to the present invention. Wherein, based on the total amount of non-aqueous electrolytic solution, the content of lithium hexafluorophosphate is 12% by weight, the content of pteridine type compound is 0.1% by weight, the content of sulfone is 0.35% by weight, and the content of ethylene carbonate and diethyl carbonate Based on the total amount, the content of ethylene carbonate was 20% by weight.

[0083] (2) Preparation of lithium ion battery

[0084] In this example, a metal lithium sheet with a thickness of 600 μm was used as the negative electrode, and a polyethylene / ...

Embodiment 2

[0091] Adopt the method identical with embodiment 1 to prepare non-aqueous electrolytic solution and lithium ion battery, difference is, in step (1), the pteridine type compound that adopts is: Furthermore, the content of the pteridine-type compound was 0.5% by weight based on the total amount of the non-aqueous electrolytic solution.

Embodiment 3

[0093] Adopt the method identical with embodiment 1 to prepare non-aqueous electrolytic solution and lithium ion battery, difference is, in step (1), the pteridine type compound that adopts is: In addition, the content of the pteridine-type compound was 1% by weight based on the total amount of the non-aqueous electrolytic solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com