A high and low voltage prefabricated substation

A pre-installed substation, high and low voltage technology, applied in the field of substations, can solve problems such as uneven heat dissipation in the station building, and achieve the effect of protecting normal operation, preventing sliding, and ensuring safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

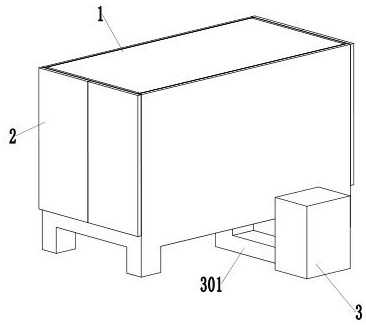

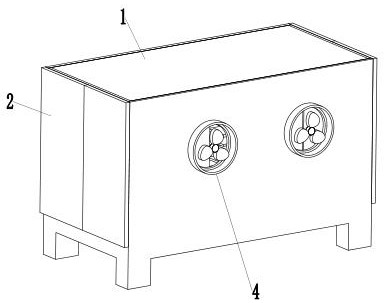

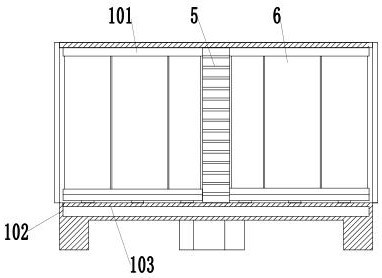

[0029] Such as Figure 1-7 As shown, a high and low voltage prefabricated substation includes a station building 1, a sealed door 2, a refrigeration device 3, an exhaust fan 4, and a heat dissipation pipe 5. Both ends of the station building 1 are provided with a sealed door 2. The lower end of the station building 1 is provided with a flow equalizer 103, and there is a gap between the flow balance plate 103 and the lower end surface of the station building 1. The flow equalizer 103 is perpendicular to the front and rear facades of the airtight door 2 and the station building 1. The side walls are connected, and the two sides of the lower end of the station building 1 are equipped with windshields 102, and the inner sides of the windshields 102 are connected to the left and right sides of the airtight door 2 parallel to the inside of the windshield 102. 103 is evenly provided with ventilation holes, and the middle part of the lower end of the flow equalizer 103 is horizontally...

Embodiment 2

[0031] Such as Figure 1-7 As shown, a high and low voltage prefabricated substation includes a station building 1, a sealed door 2, a refrigeration device 3, an exhaust fan 4, and a heat dissipation pipe 5. Both ends of the station building 1 are provided with a sealed door 2. The lower end of the station building 1 is provided with a flow equalizer 103, and there is a gap between the flow balance plate 103 and the lower end surface of the station building 1. The flow equalizer 103 is perpendicular to the front and rear facades of the airtight door 2 and the station building 1. The side walls are connected, and the two sides of the lower end of the station building 1 are equipped with windshields 102, and the inner sides of the windshields 102 are connected to the left and right sides of the airtight door 2 parallel to the inside of the windshield 102. 103 is evenly provided with ventilation holes, and the middle part of the lower side of the flow equalizer 103 is horizontall...

Embodiment 3

[0034] Such as Figure 1-7 As shown, a high and low voltage prefabricated substation includes a station building 1, a sealed door 2, a refrigeration device 3, an exhaust fan 4, and a heat dissipation pipe 5. Both ends of the station building 1 are provided with a sealed door 2. The lower end of the station building 1 is provided with a flow equalizer 103, and there is a gap between the flow balance plate 103 and the lower end surface of the station building 1. The flow equalizer 103 is perpendicular to the front and rear facades of the airtight door 2 and the station building 1. The side walls are connected, and the two sides of the lower end of the station building 1 are equipped with windshields 102, and the inner sides of the windshields 102 are connected to the left and right sides of the airtight door 2 parallel to the inside of the windshield 102. 103 is evenly provided with ventilation holes, and the middle part of the lower side of the flow equalizer 103 is horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com