A power battery cooling device based on the principle of ion wind

A power battery and cooling device technology, applied in corona discharge devices, secondary batteries, battery pack components, etc., can solve the problems of uneven heat dissipation, excessive power consumption, slow cooling speed, etc., to solve the problem of uneven heat dissipation , Increase the thermal conductivity, improve the effect of air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

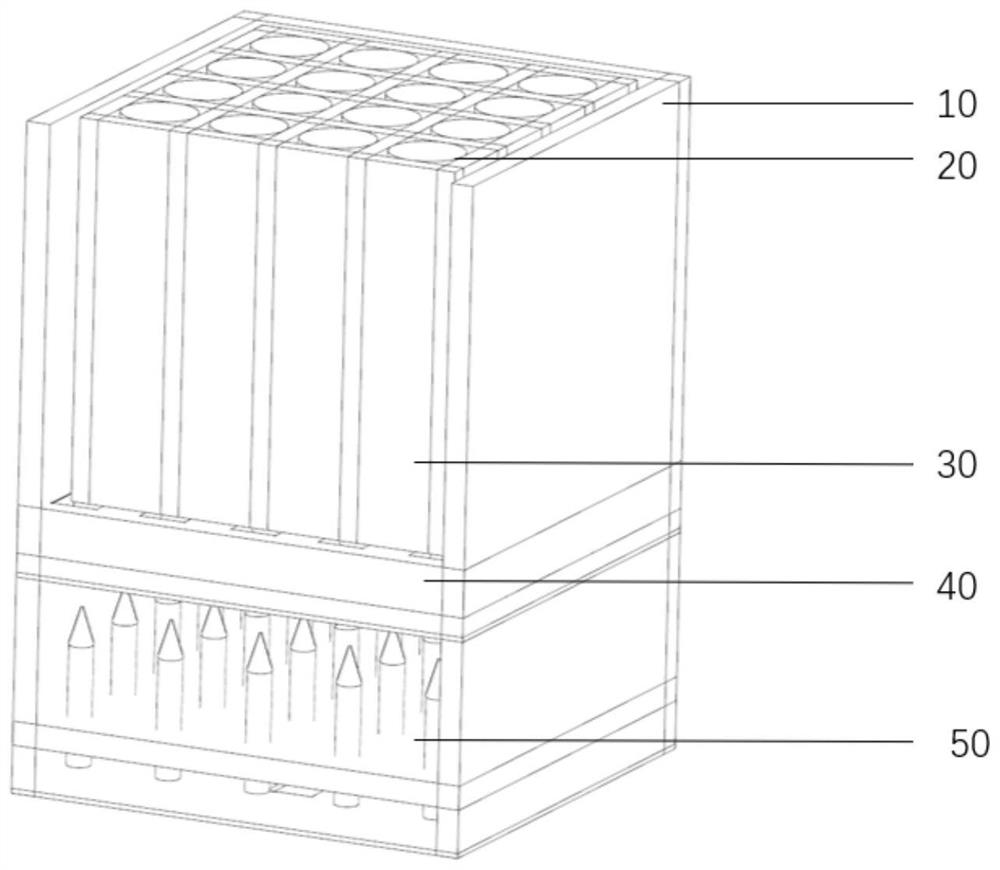

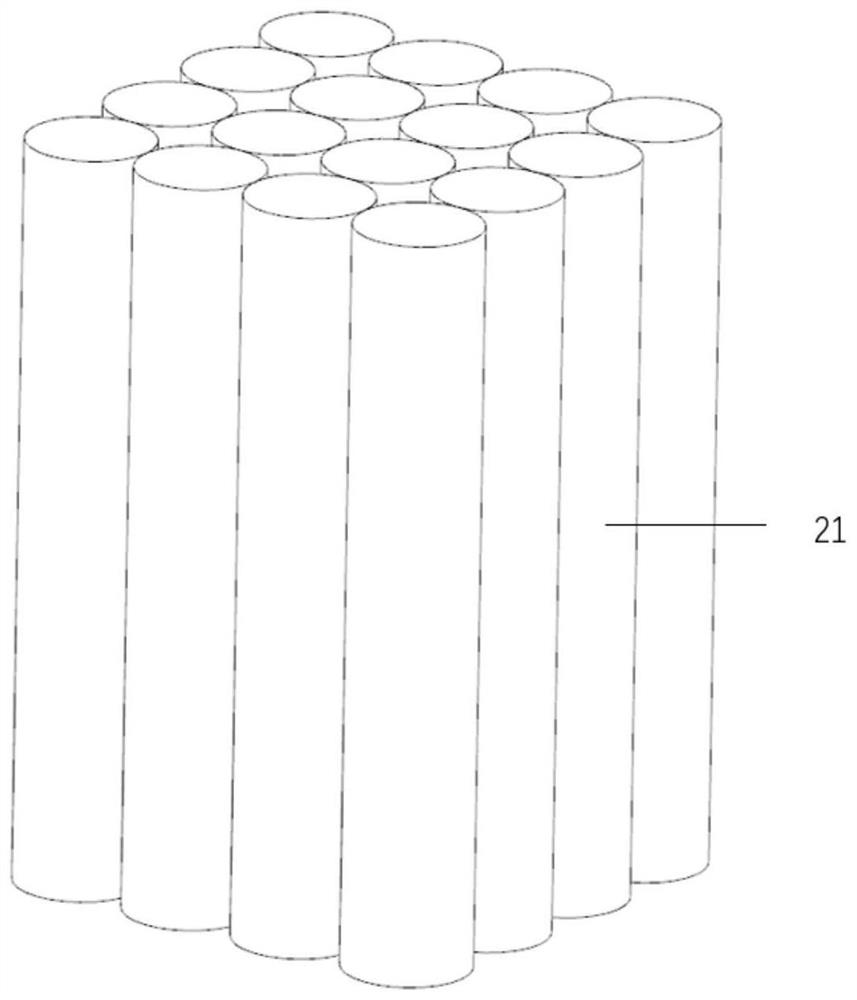

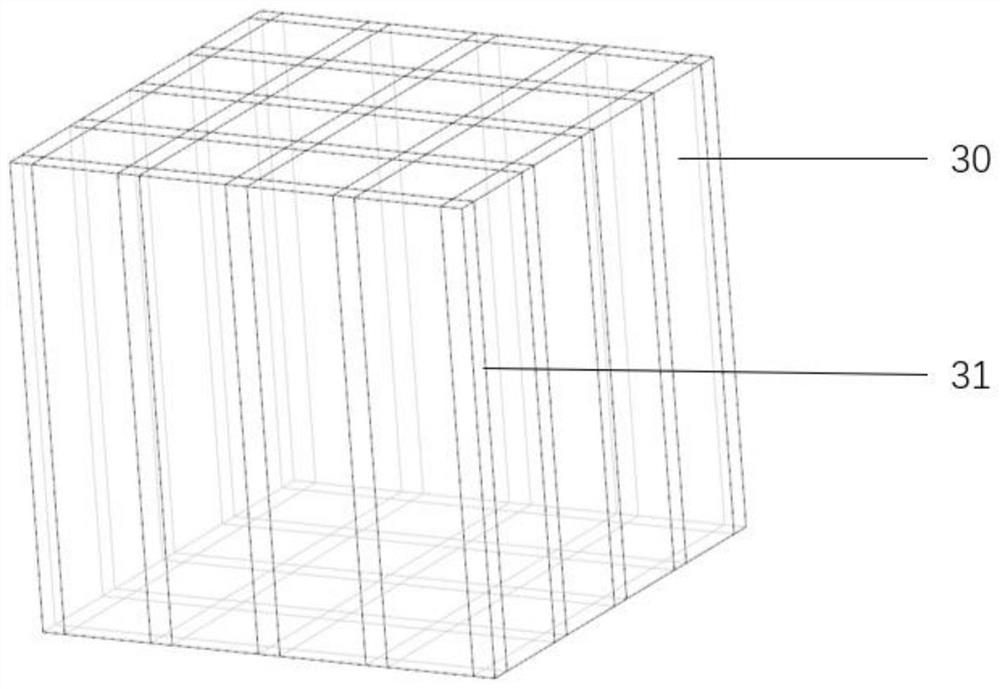

[0028] refer to figure 1 The power battery cooling device based on the ion wind principle of the present invention includes: a housing 10, a power battery module 20, a heat dissipation metal fin module 30, a heat dissipation base 40 and an ion wind heat dissipation module 50, a heat dissipation metal fin module 30, The heat dissipation base 40 and the ion wind heat dissipation module 50 are sequentially arranged inside the cuboid housing 10 .

[0029] Such as Figure 6 As shown, the ion wind cooling module 50 is fixed on the bottom of the housing 10 by bolts, and there are any number of holes on the bottom of the housing 10 to ensure that the ion wind cooling module 50 has a continuous stream of air influx during the working process, so that the corona discharge The process proceeds normally. The ion wind heat dissipation module 50 is located directly below the heat dissipation base 40, the main body of the ion wind heat dissipation module 50 is an ion wind generator, the em...

Embodiment 2

[0034] The emitter 51 of the ion wind generator adopts a wire electrode, and the receiving pole 52 adopts a mesh electrode, such as Figure 7 As shown, the wire electrode adopts metal thin wires, and the metal thin wires are wound along the emitter support 53, and are arranged side by side, and the distance between the wires is 5mm; in order to prevent the distance from being too small or too large, causing the ion wind generator The generated ion wind is small, and the distance L between the wire electrode and the mesh electrode is 5-10mm. Other components of the power battery cooling device are the same as those in Embodiment 1.

Embodiment 3

[0036] The emitter 51 of the ion wind generator adopts a needle electrode, and the receiver 52 adopts a plate electrode, such as Figure 8 As shown, the plate-shaped electrode is a metal plate, and a certain number of through holes are punched on the metal plate, and the through holes can allow ion wind to blow out therefrom to dissipate heat from the power battery module 20 . Other components of the power battery cooling device are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com