Processing method of medicinal material processed ginger slices and product

A technology for the processed ginger and decoction pieces, which is applied in the field of processing medicinal materials, the processed ginger, and can solve the problems of uneven quality of the processed products, weakened efficacy of the processed ginger, and rough preparation process, and achieves easy control of the processing level and rapid heating. , The effect of processing good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of ginger processing technology, comprises the steps:

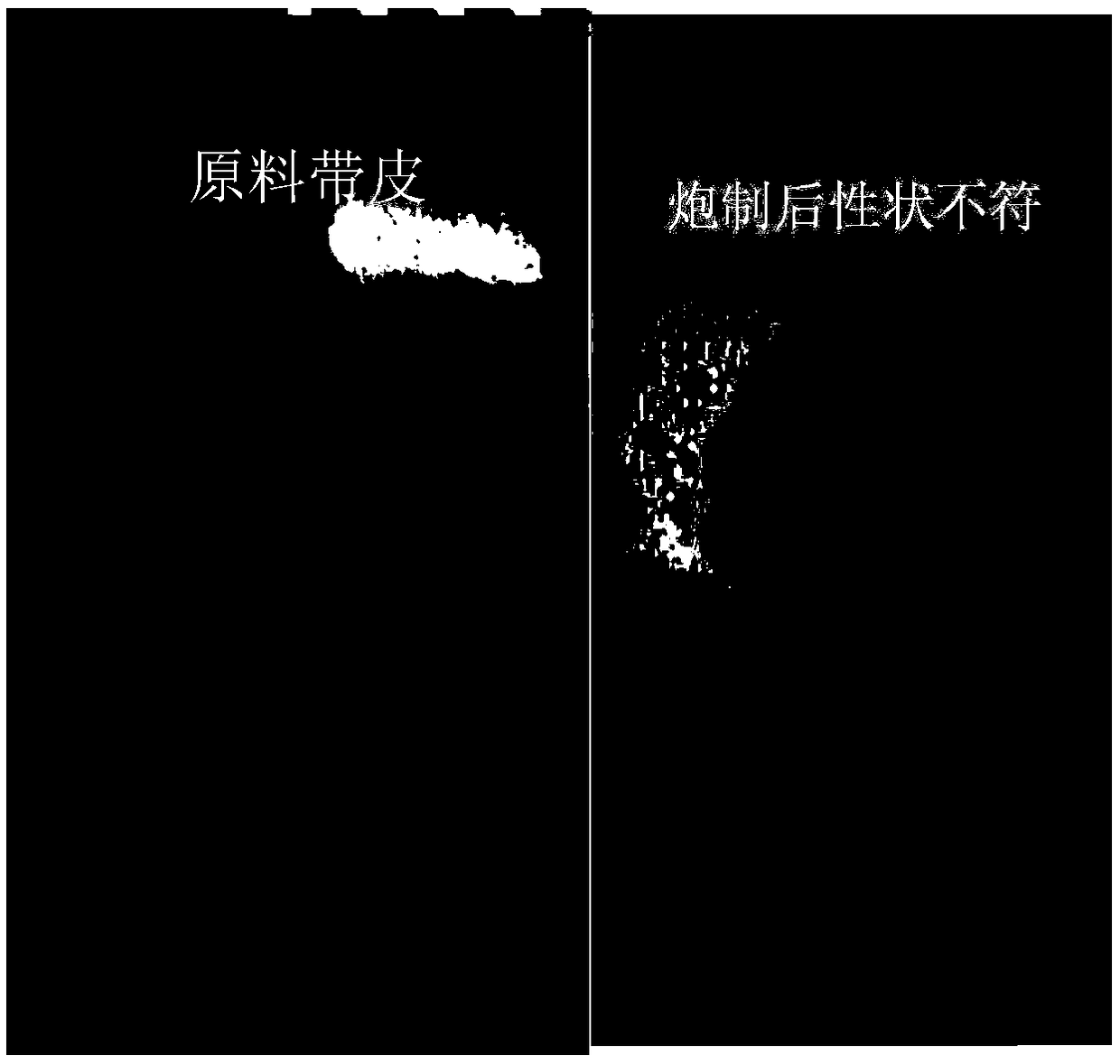

[0047] The steps of bumping the skin: Put the dried ginger into the equipment and turn it over, knock off the outer skin, take it out, and sieve the medicine crumbs:

[0048] The steps of frying river sand: take river sand with a particle size of 5mm, put it in a hot pot, stir fry the river sand with a strong fire at a temperature of 240-260°C, and fry until the river sand is smooth; the dried ginger and The amount ratio of river sand is 1:0.1;

[0049] Steps of sand scalding: Put the dried ginger into the smooth river sand, stir-fry continuously, stir-fry for 14 minutes until the ginger is bulging and the surface is brown;

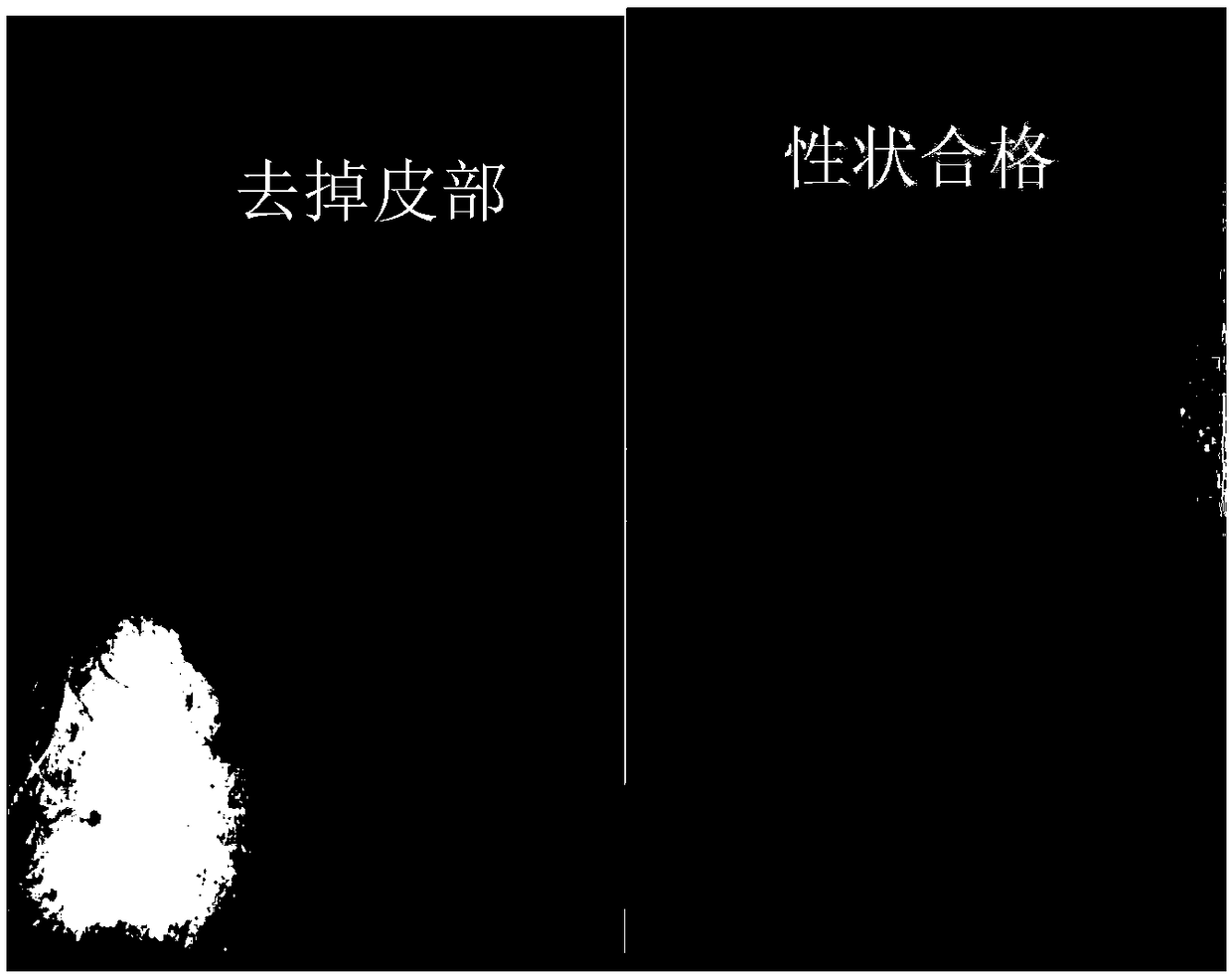

[0050] Steps of sieving: sieve while hot to remove sand, take the sieve residue, and let it cool naturally to obtain Paojiang decoction pieces.

Embodiment 2

[0052] A kind of ginger processing technology, comprises the steps:

[0053] The steps of bumping the skin: Put the dried ginger into the equipment and turn it over, knock off the outer skin, take it out, and sieve the medicine crumbs:

[0054] The steps of frying river sand: take river sand with a particle size of 5mm, put it in a hot pot, stir fry the river sand with a strong fire at a temperature of 240°C, and fry until the river sand is smooth; the dried ginger and the river sand The dosage ratio is 1:0.1;

[0055] Steps of sand scalding: Put the dried ginger into the smooth river sand, stir fry continuously, stir fry for 15 minutes until the ginger is bulging and the surface is brown;

[0056] The steps of sieving: sieve while it is hot to remove sand, take the residue of the sieve, let it cool naturally, and then get the Pao Jiang decoction pieces, such as figure 2 shown.

Embodiment 3

[0058] A kind of ginger processing technology, comprises the steps:

[0059] The steps of bumping the skin: Put the dried ginger into the equipment and turn it over, knock off the outer skin, take it out, and sieve the medicine crumbs:

[0060]The steps of frying river sand: take river sand with a particle size of 5mm, put it in a hot pot, stir fry the river sand with a strong fire at a temperature of 240°C, and fry until the river sand is smooth; the dried ginger and the river sand The dosage ratio is 1:0.1;

[0061] Steps of sand scalding: Put the dried ginger into the smooth river sand, stir fry continuously, stir fry for 16 minutes until the ginger is bulging and the surface is brown;

[0062] Steps of sieving: sieve while hot to remove sand, take the sieve residue, and let it cool naturally to obtain Paojiang decoction pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com