Pan-tilt for inspection robot of transformer substation

A technology for inspection robots and substations, applied in the field of pan/tilt, can solve problems such as difficult to meet high-precision requirements, limit robot usage scenarios, and low steering accuracy of pan/tilt, and achieve the effect of convenient design, simple structure, and convenient wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

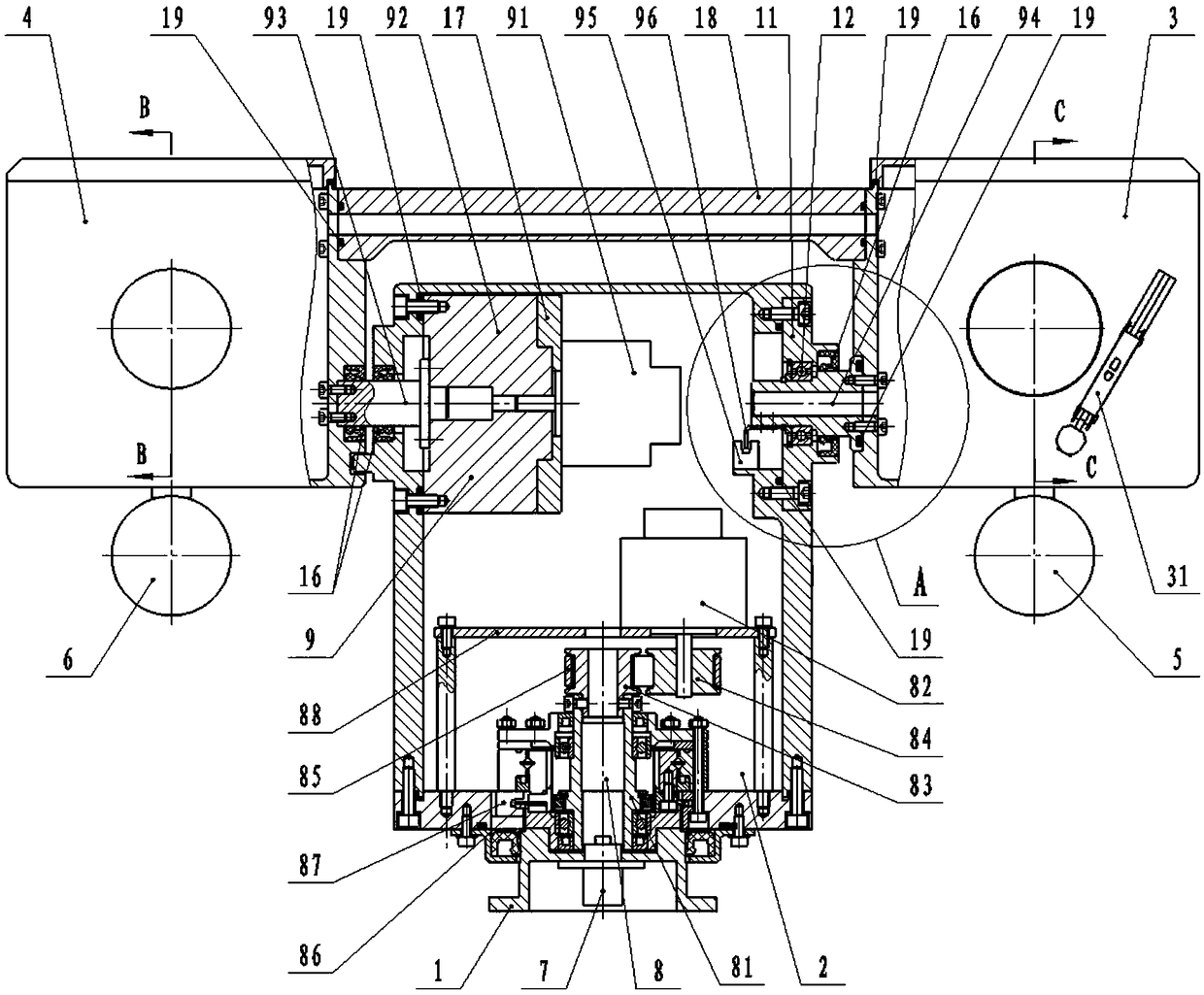

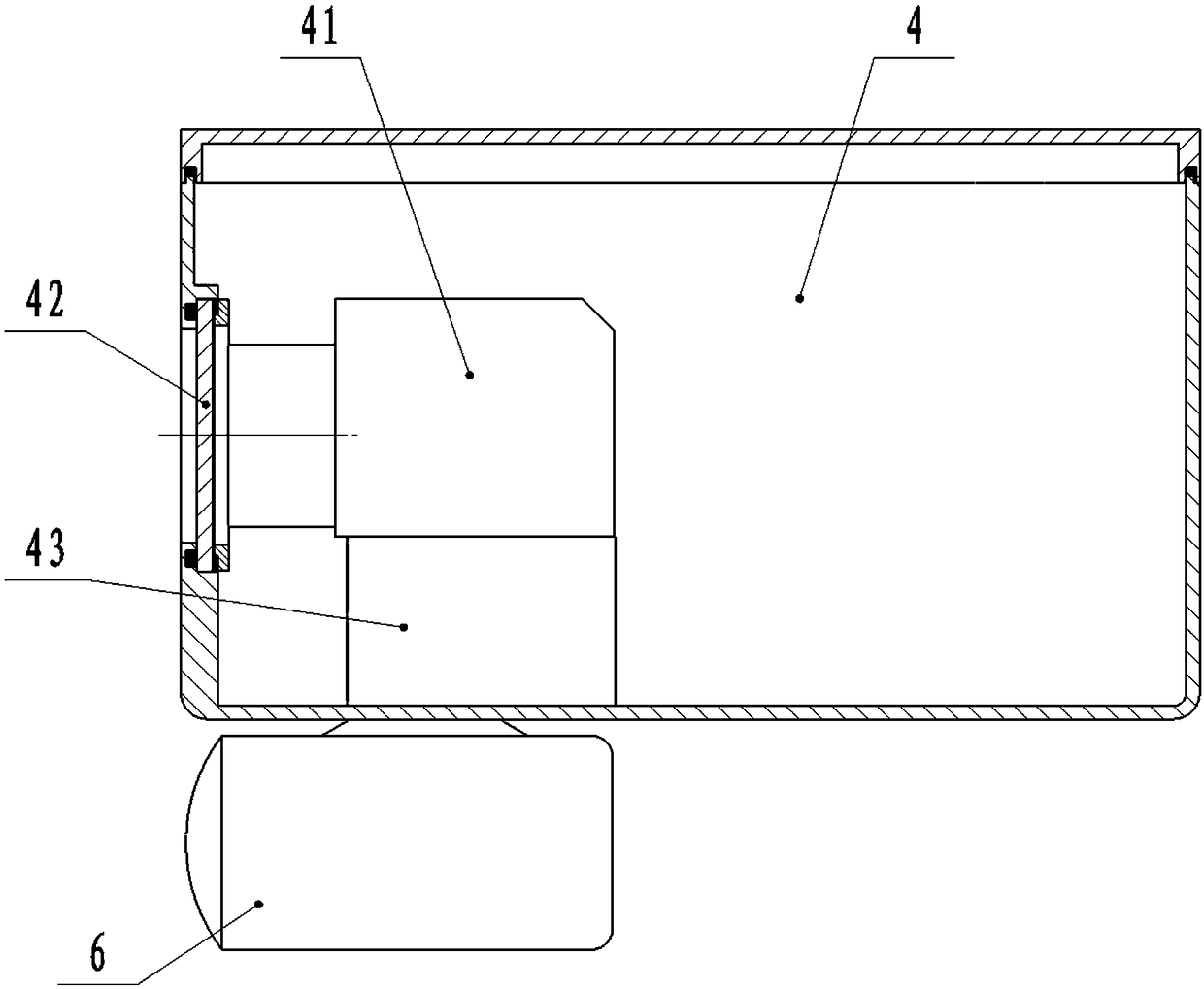

[0031] A substation inspection robot platform, comprising a fixed seat 1, a main cabin 2, a visible light camera cabin 3, an infrared camera cabin 4, a supplementary light 5 and a pickup 6, and the visible light camera cabin 3 and the infrared camera cabin 4 are respectively fixed On both sides opposite to the main cabin 2, and between the visible light camera cabin 3 and the infrared camera cabin 4, a connecting piece 18 is provided. Vertical drive mechanism 9;

[0032] A conductive slip ring 7 is fixedly installed in the fixed seat 1, and the horizontal driving mechanism 8 is fixed on the upper part of the conductive slip ring 7. The horizontal driving mechanism 8 includes a harmonic reducer I81 fixed on the bottom wall of the main cabin 2, Synchronous wheel I 83, synchronous wheel II 84, synchronous belt 85 and servo motor I 82 with encoder, said harmonic reducer I 81 output end slot is fixed with photoelectric switch trigger I 86, installed on the bottom wall of main cabin...

Embodiment 2

[0038] On the basis of Embodiment 1, the output end of the harmonic reducer I81 is connected to the fixed seat 1, and the input end is connected to the synchronous wheel I83. The synchronous wheel I83 is connected to the synchronous wheel II84 through the synchronous belt 85. The synchronous wheel II84 is fixedly connected with the output shaft of the servo motor I82 with an encoder, the servo motor I82 with an encoder is installed on the motor mounting frame 88, and the harmonic reducer I81 is a hollow type reducer, which is convenient for internal use The cable is routed, and the inner hole of the synchronous wheel II84 is coaxially fixedly connected with the output shaft of the servo motor I82 with an encoder, which can ensure that the inner hole of the synchronous wheel II84 rotates synchronously with the output shaft of the servo motor I82 with an encoder. The synchronous wheel Ⅰ83 and synchronous wheel Ⅱ84 have the same number of teeth to ensure synchronous rotation. The ...

Embodiment 3

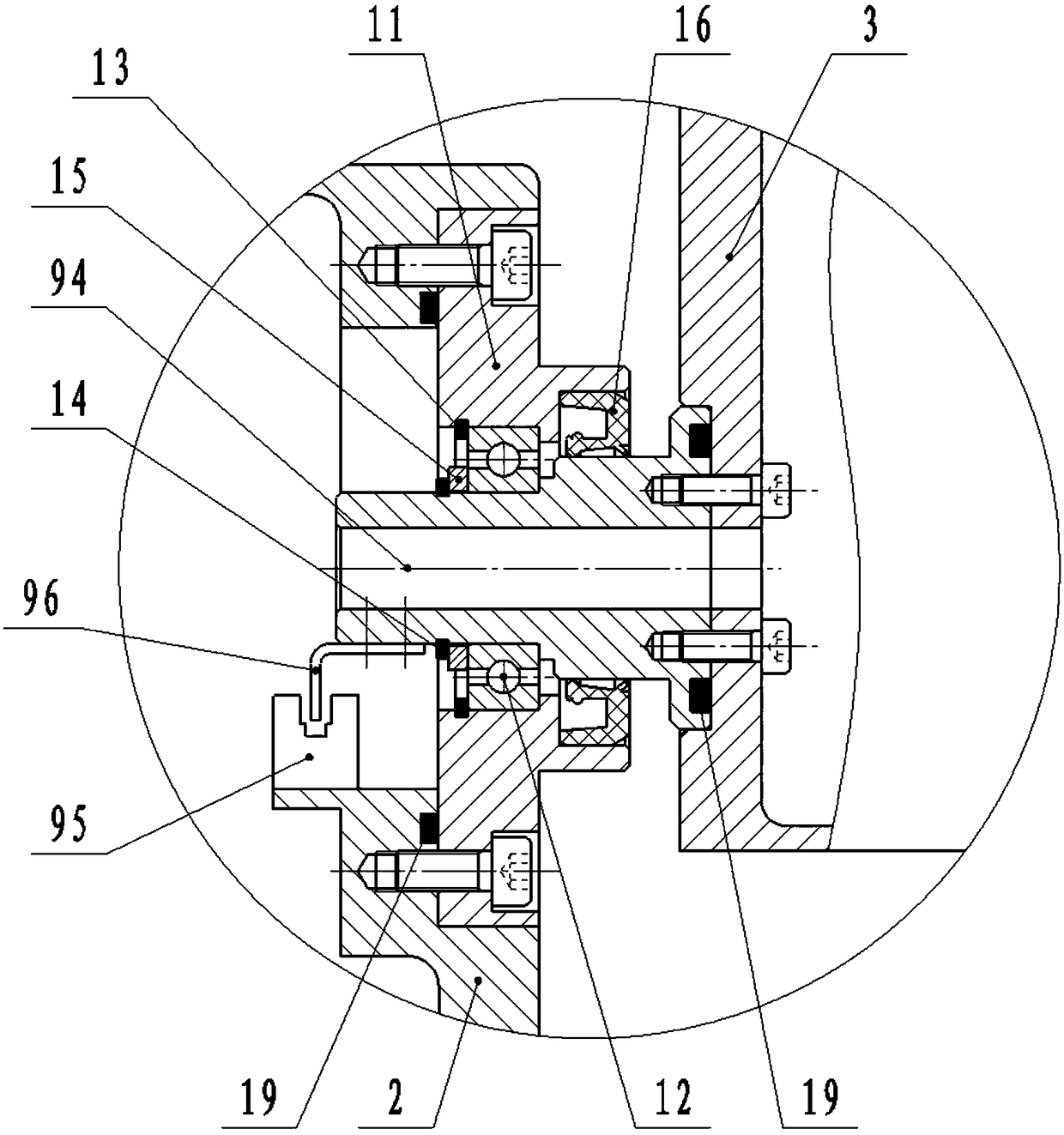

[0040] On the basis of Embodiment 1, one end of the passive shaft 94 is fixedly connected to the visible light camera cabin 3, and the other end is bearing-connected to the main cabin 2. The main cabin 2 is provided with a bearing seat 11, and the bearing seat 11 is provided with Bearing 12, a circlip 13 for the hole and a circlip 14 for the shaft, a shaft shoulder retaining ring 15 is installed on the outer cylindrical surface of the driven shaft 94, and the right end surface of the shoulder retaining ring 15 is tightly connected to the left end surface of the inner ring of the bearing 12. The circlip 13 for the hole is installed in the groove processed by the bearing seat 11 for the axial limit of the outer ring of the bearing 12, and the circlip 14 for the shaft is installed in the groove processed by the driven shaft 94 for the shaft shoulder The stop ring 15 and the axial limit of the inner ring of the bearing 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com