Automatic opening cutting equipment for silicon rubber valves

A silicone valve and equipment technology, applied in metal processing and other directions, can solve the problems that affect the function of the silicone valve, affect the liquid outflow and the verticality of the water flow, and cannot be completely flushed, so as to ensure accuracy and incision efficiency, improve efficiency and The effect of uniformity and improved operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

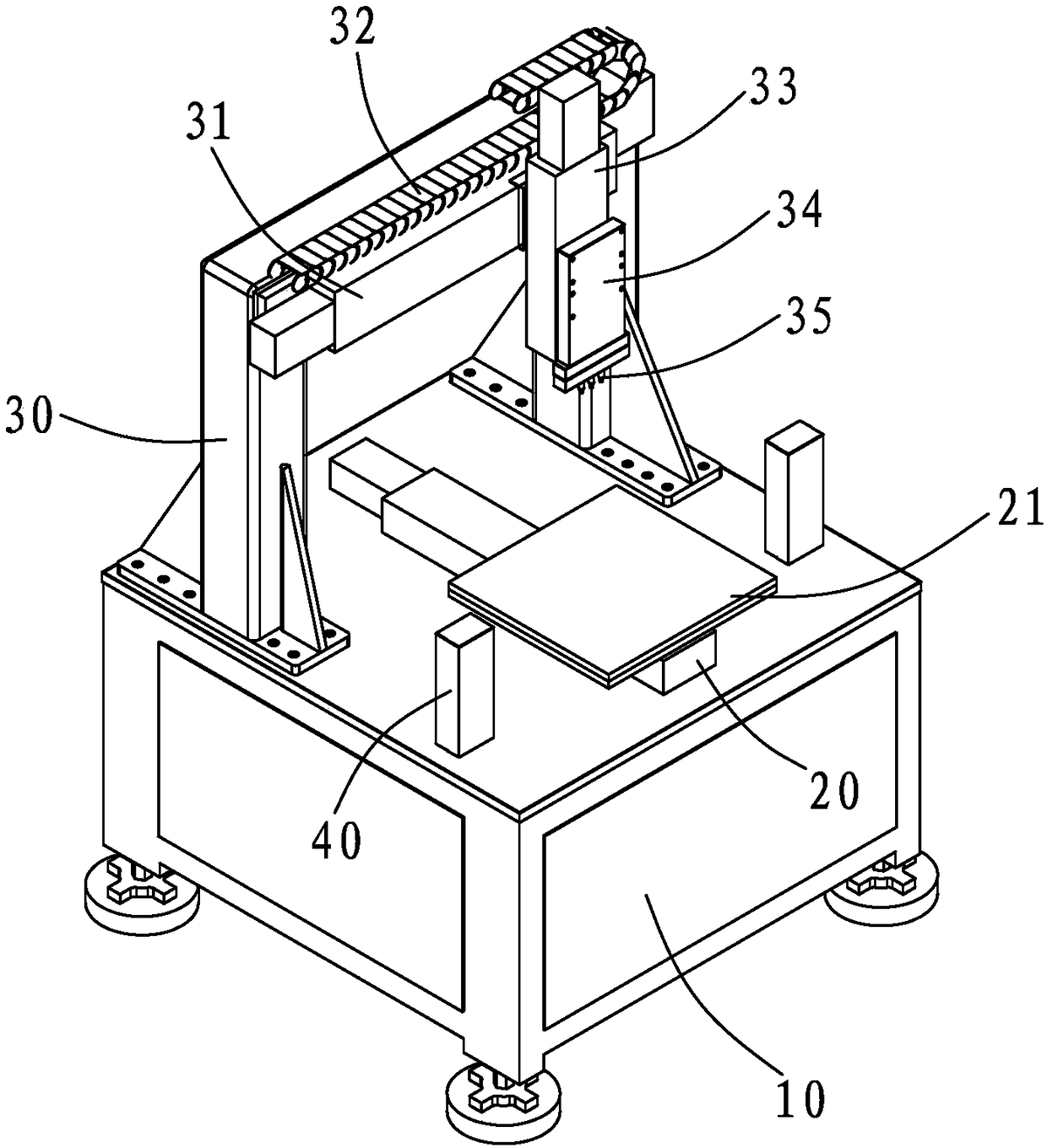

[0021] refer to figure 1 , the automatic silicone valve cutting device provided by the present invention includes a workbench 10, a Z-direction servo assembly and a two-dimensional servo assembly arranged on the workbench 10; the Z-direction servo assembly includes a Z-direction servo assembly arranged on the workbench 10 The main shaft 20, and the positioning tool 21 driven by the Z-direction servo main shaft 20, the surface of the positioning tool 21 is provided with a layer of flexible film with a cushioning effect, and the positioning tool 21 is provided with multiple sets of parallel positioning blocks for the positioning of the silicone valve, The cutting tool is provided with a cutter corresponding to the number of positioning blocks in each group, and through the step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com